Didn't sleep well, so got up to tinker with the camera setup in the EXT. The trailer hitch camera was acting up, so did a little testing. Disconnected the power to the roof camera, and it started working properly again. So my conclusion was, using the amp turn-on signal to activate the amp, and power 2 cameras simultaneously, wasn't providing enough current. OK, lemme throw a relay in there, pull power from the 4 gauge 12V line, and use the amp turn on circuit to activate it. Easy right?

Well I didn't have a spare relay lying around.

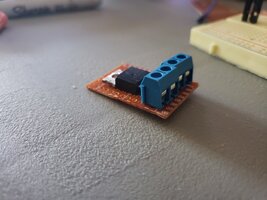

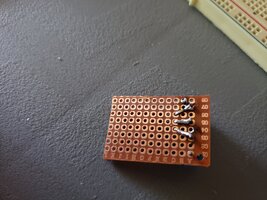

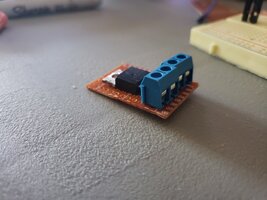

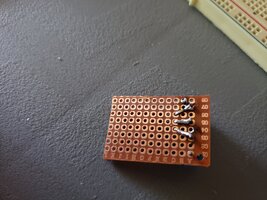

Rooted through the random parts drawers, and came up with an idea. Cut up a small piece of perf board, an NPN transistor, and a couple of screw down wire terminals, to make a solid state relay circuit.

Pulled the lift gate trim, and tried fishing the camera wires through the boot. No dice, the plugs were just too big, so slit the boots, and fished them through that way. Was going to fit some split loom on there, but can't find it. So I'll revisit that later. Drilled a couple small holes and fitted the camera close to the glass. I may need to put some foam under the base, because when I checked the image while the bass was hitting, the camera was nodding with the beat

Shot with the glass open, and the lift gate open.

Ran my wires through the headliner and down the D pillar, taped some of them, and taped the relay circuit to a wire bundle. Did a couple of quick tests, and now both cameras were working nice and clear through the HU.

Buttoned everything up and went for a drive, after a few minutes, the old camera started getting fuzzy again, and eventually stopped giving me a signal. I dunno WTH is going on with it

Rooted through the random parts drawers, and came up with an idea. Cut up a small piece of perf board, an NPN transistor, and a couple of screw down wire terminals, to make a solid state relay circuit.

Rooted through the random parts drawers, and came up with an idea. Cut up a small piece of perf board, an NPN transistor, and a couple of screw down wire terminals, to make a solid state relay circuit.

Shot with the glass open, and the lift gate open.

Shot with the glass open, and the lift gate open.

definitely the deepest I've been into the TB, but was quite an accomplished feeling remembering how smooth the old gal was capable of running. It's incredible.

definitely the deepest I've been into the TB, but was quite an accomplished feeling remembering how smooth the old gal was capable of running. It's incredible.

Before

Before