@Blckshdw you're an absolute GRAND SLAMMAH. I deeply appreciate your effort and attention to effect this provision. Absolutely clinch. VERY APPRECIATED.Pulled this out of GMSI. If you're familiar with downloading torrents and working with VMware virtual machines, you can get a copy here

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What did you do to your GMT today? [Part II]

- Thread starter Mooseman

- Start date

THE SHINE!!! lololol MY EYES lololol!!! Those are gonna chooch well into the 2030's as long as you stay away from Minnesota road saltBed lined the tank straps and pump top. No wonder these rust so badly. They're just bare steel. Why couldn't they have stayed with plastic? Oh yeah, right!

View attachment 106205View attachment 106206View attachment 106207

Is it any worse than Canadian road salt?THE SHINE!!! lololol MY EYES lololol!!! Those are gonna chooch well into the 2030's as long as you stay away from Minnesota road salt

I think THE worse is brine. It's literally liquid salt. They use it in NY as well as northern Ontario. I've seen the effects on my son's 2011 Silvy frame that we had to fix. Both rear crossmembers were gone. He had already replaced his fuel pump due to rust through.

I think THE worse is brine. It's literally liquid salt. They use it in NY as well as northern Ontario. I've seen the effects on my son's 2011 Silvy frame that we had to fix. Both rear crossmembers were gone. He had already replaced his fuel pump due to rust through.northcreek

Member

And according to this,plenty of it:Is it any worse than Canadian road salt?I think THE worse is brine. It's literally liquid salt. They use it in NY as well as northern Ontario

Do they use salt on roads in New York state?

The Authority's primary weapon to fight roadway icing is rock salt. The average annual usage for the past ten years is approximately 180,000 tons.

180,000 TONS. Let's work the math: 180,000 x 2000 (pounds per ton) = 360,000,000 Pounds. 360 Million pounds of salt.And according to this,plenty of it:

Do they use salt on roads in New York state?

The Authority's primary weapon to fight roadway icing is rock salt. The average annual usage for the past ten years is approximately 180,000 tons.

With 365 days a year that works out to nearly One Million pounds of salt Per Day!

With 365 days a year that works out to nearly One Million pounds of salt Per Day!  . Actually 986,301 pounds of salt per day. wow!

. Actually 986,301 pounds of salt per day. wow!Bah, that's nothing. The city of Toronto alone lays down 150,000 metric tonnes (that's 165,000 US tons). Ottawa, where I am, which is usually colder than Toronto, does 185,000 metric tons (204,000 US tons). All of Ontario lays 5-6 MILLION metric tons per year. That's insane!

There's gotta be something better. It's also harmful to the environment.

There's gotta be something better. It's also harmful to the environment.

Dude. That's intense. @Redbeard & @northcreek those calculations were an invitation to enormity yes?? lololol WOW!!!! I will say that the only point of differentiation betwixt those road salt *flavors* that might perhaps be involved is the *actual* ore that's in physical deposition to the undercarriage, as I still (now 11 years later) find rust from the rust belt adhered to the exterior gloss & var. coatings of *THE BEAST* that once trudged the (at the time in 2011) coldest winter in decades to find Grand Rapids MinnesotaIs it any worse than Canadian road salt?I think THE worse is brine. It's literally liquid salt. They use it in NY as well as northern Ontario. I've seen the effects on my son's 2011 Silvy frame that we had to fix. Both rear crossmembers were gone. He had already replaced his fuel pump due to rust through.

****PUBLIC NUDITY WARNING - EXPLICIT - GRAPHIC CONTENT****  ((((Freshly Shaved @5,000 "grit" /123 Block Commutator Massage Strop, JUST ABOUT to get all dolled up in fresh torque&angle&ACDelco goo after a few more gulps of lacquer thinner to the thread ports/decks and last looks to a soft plastic **delicata** vacuum tip sonata

((((Freshly Shaved @5,000 "grit" /123 Block Commutator Massage Strop, JUST ABOUT to get all dolled up in fresh torque&angle&ACDelco goo after a few more gulps of lacquer thinner to the thread ports/decks and last looks to a soft plastic **delicata** vacuum tip sonata

((((Freshly Shaved @5,000 "grit" /123 Block Commutator Massage Strop, JUST ABOUT to get all dolled up in fresh torque&angle&ACDelco goo after a few more gulps of lacquer thinner to the thread ports/decks and last looks to a soft plastic **delicata** vacuum tip sonata

((((Freshly Shaved @5,000 "grit" /123 Block Commutator Massage Strop, JUST ABOUT to get all dolled up in fresh torque&angle&ACDelco goo after a few more gulps of lacquer thinner to the thread ports/decks and last looks to a soft plastic **delicata** vacuum tip sonata

Attachments

flyboy2610

Member

A naked engine! My eyes, my eyes!****PUBLIC NUDITY WARNING - EXPLICIT - GRAPHIC CONTENT****((((Freshly Shaved @5,000 "grit" /123 Block Commutator Massage Strop, JUST ABOUT to get all dolled up in fresh torque&angle&ACDelco goo after a few more gulps of lacquer thinner to the thread ports/decks and last looks to a soft plastic **delicata** vacuum tip sonata

I saw the inside of my 02 way too often. So much so that it was like being married

@flyboy2610 Bahahahahaha & @Mooseman Gahahahahahaha - 100% Intimacy!!!! I'm sure it appreciated all that T.L.C.!! Oh man! lololol

Did the fuel pump on the TB. Despite having a hoist and tons of tools, took over 6 hours although the DIY shop owner was on the phone for an hour so he only charged me for 5 hours. The straps were in relatively good condition and the bolts came out with breaking or spinning in the frame. This thing then fought me on everything. Broke almost all the line clips, the fuel line was rusted to the pump so had to fiddle with the plastic spacer that goes in it, the filler hose was just being a PITA and the old lock ring wouldn't budge, even with an air hammer (albeit a weak cheap one) but it eventually came off. Hell, even the old pump wouldn't come out as it somehow expanded and wouldn't fit through the hole. I wasn't gentle anymore.

Getting the new lock ring on was no picnic neither. It just wouldn't turn all the way. Had to bend the tank's tangs back a tiny bit to allow the ring to go to full lock. Then more fun fixing the fuel line connector, replacing the broken clips and putting it back into place. One of the bigger clips that broke I didn't have a replacement so I used a zip tie instead. It's just an evap line so it'll be good enough. And the final fuel line connector was just being a PITA to go back in despite using some lube on it. Ran it before the final bolt up to ensure no leaks.

And while I was waiting for my guy to get off the phone, I did a quick check of the front steering and... the right outer tie rod is shot. So much for Mevocrap's TTX.

Anyway, at least I don't get high on gas fumes anymore.

Getting the new lock ring on was no picnic neither. It just wouldn't turn all the way. Had to bend the tank's tangs back a tiny bit to allow the ring to go to full lock. Then more fun fixing the fuel line connector, replacing the broken clips and putting it back into place. One of the bigger clips that broke I didn't have a replacement so I used a zip tie instead. It's just an evap line so it'll be good enough. And the final fuel line connector was just being a PITA to go back in despite using some lube on it. Ran it before the final bolt up to ensure no leaks.

And while I was waiting for my guy to get off the phone, I did a quick check of the front steering and... the right outer tie rod is shot. So much for Mevocrap's TTX.

Anyway, at least I don't get high on gas fumes anymore.

Not getting high on gas fumes anymore is *KEY* - I like your quote: "I wasn't gentle anymore". Those photos tell the tale of a poor soldier fallen prey to the *SEDITION OF OXIDATION" :V :o ;Did the fuel pump on the TB. Despite having a hoist and tons of tools, took over 6 hours although the DIY shop owner was on the phone for an hour so he only charged me for 5 hours. The straps were in relatively good condition and the bolts came out with breaking or spinning in the frame. This thing then fought me on everything. Broke almost all the line clips, the fuel line was rusted to the pump so had to fiddle with the plastic spacer that goes in it, the filler hose was just being a PITA and the old lock ring wouldn't budge, even with an air hammer (albeit a weak cheap one) but it eventually came off. Hell, even the old pump wouldn't come out as it somehow expanded and wouldn't fit through the hole. I wasn't gentle anymore.

Getting the new lock ring on was no picnic neither. It just wouldn't turn all the way. Had to bend the tank's tangs back a tiny bit to allow the ring to go to full lock. Then more fun fixing the fuel line connector, replacing the broken clips and putting it back into place. One of the bigger clips that broke I didn't have a replacement so I used a zip tie instead. It's just an evap line so it'll be good enough. And the final fuel line connector was just being a PITA to go back in despite using some lube on it. Ran it before the final bolt up to ensure no leaks.

And while I was waiting for my guy to get off the phone, I did a quick check of the front steering and... the right outer tie rod is shot. So much for Mevocrap's TTX.

Anyway, at least I don't get high on gas fumes anymore.

View attachment 106266View attachment 106267View attachment 106268

- STOKED that you didn't have any leaks to the fresh install. All that business can now just be a memory. Glad you got it whipped.

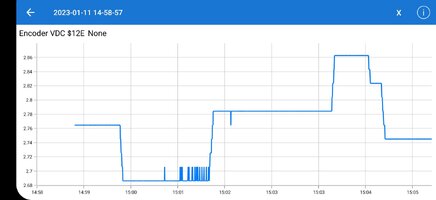

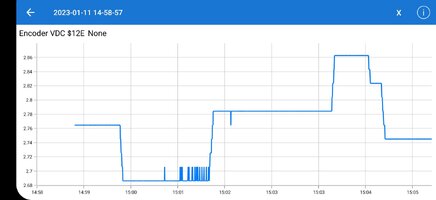

- STOKED that you didn't have any leaks to the fresh install. All that business can now just be a memory. Glad you got it whipped.So the last few days had me playing with the Tech 2 and the TCCM.

By monitoring voltages with a DMM I discovered that the Tech 2 does NOT release the electric shift motor brake when using the "special functions" to energize the Motor A and Motor B circuits.

Not having actually read any Tech 2 instructions for such functions I speculate that perhaps this function is designed to allow testing of amperage draws? Still haven't looked that up.

Anyway, I further found that these circuits appear to be energized for just 5 seconds or so in the use of these "special functions". Indeed, trying to execute the command a second time without a rest period yields the error message about it being within 10 seconds of the prior execution and thus is not allowed.

Going further I noticed the encoder return signal changed very slowly during those 5 seconds of Motor Circuit application indicating that even with the electric brake applied my shift motor moved ever so slightly.

Makes me wonder if my brake is aging or is it meant to operate this way.

Anyway, as for "what did I do to my GMT360 today" I sucessfully activated each of these Motor A & B circuits using commands from my phone and Bluetooth adapter and "adjusted" the position of my shift motor just slightly. Why do such a thing? Just to see if I could of course!

By monitoring voltages with a DMM I discovered that the Tech 2 does NOT release the electric shift motor brake when using the "special functions" to energize the Motor A and Motor B circuits.

Not having actually read any Tech 2 instructions for such functions I speculate that perhaps this function is designed to allow testing of amperage draws? Still haven't looked that up.

Anyway, I further found that these circuits appear to be energized for just 5 seconds or so in the use of these "special functions". Indeed, trying to execute the command a second time without a rest period yields the error message about it being within 10 seconds of the prior execution and thus is not allowed.

Going further I noticed the encoder return signal changed very slowly during those 5 seconds of Motor Circuit application indicating that even with the electric brake applied my shift motor moved ever so slightly.

Makes me wonder if my brake is aging or is it meant to operate this way.

Anyway, as for "what did I do to my GMT360 today" I sucessfully activated each of these Motor A & B circuits using commands from my phone and Bluetooth adapter and "adjusted" the position of my shift motor just slightly. Why do such a thing? Just to see if I could of course!

For mine, parked it in the driveway last night. @kurupt stopped by this morning with his XUV, as he needed to get his midgate down to prep for an upcoming move, but the midgate window regulator had broken and he couldn't lower the window in order to drop the gate.

Got the inner panel off, only broke 1 clip. Managed to get the window pulled down about halfway before the steel cable in the regulator bound up, so we cut it. Problem solved. He said he was having a weird issue with the headlights sometimes going out. Switched the headlight relay with the cooling fan one for now, we definitely won't need that for a couple of months. He'll monitor how it behaves for a while and if that fixes it, he'll buy a new relay. Radio sound was also sporadic, although I think that's an old problem we never resolved, since I remember talking to him about troubleshooting the Bose amp, but we never got around to it.

Ended the visit sitting in my EXT for a bit, going over my Torque dashboards, and getting his setup again.

Got the inner panel off, only broke 1 clip. Managed to get the window pulled down about halfway before the steel cable in the regulator bound up, so we cut it. Problem solved. He said he was having a weird issue with the headlights sometimes going out. Switched the headlight relay with the cooling fan one for now, we definitely won't need that for a couple of months. He'll monitor how it behaves for a while and if that fixes it, he'll buy a new relay. Radio sound was also sporadic, although I think that's an old problem we never resolved, since I remember talking to him about troubleshooting the Bose amp, but we never got around to it.

Ended the visit sitting in my EXT for a bit, going over my Torque dashboards, and getting his setup again.

Eric04

Member

Did the fuel pump on the TB. Despite having a hoist and tons of tools, took over 6 hours although the DIY shop owner was on the phone for an hour so he only charged me for 5 hours. The straps were in relatively good condition and the bolts came out with breaking or spinning in the frame. This thing then fought me on everything. Broke almost all the line clips, the fuel line was rusted to the pump so had to fiddle with the plastic spacer that goes in it, the filler hose was just being a PITA and the old lock ring wouldn't budge, even with an air hammer (albeit a weak cheap one) but it eventually came off. Hell, even the old pump wouldn't come out as it somehow expanded and wouldn't fit through the hole. I wasn't gentle anymore.

Getting the new lock ring on was no picnic neither. It just wouldn't turn all the way. Had to bend the tank's tangs back a tiny bit to allow the ring to go to full lock. Then more fun fixing the fuel line connector, replacing the broken clips and putting it back into place. One of the bigger clips that broke I didn't have a replacement so I used a zip tie instead. It's just an evap line so it'll be good enough. And the final fuel line connector was just being a PITA to go back in despite using some lube on it. Ran it before the final bolt up to ensure no leaks.

And while I was waiting for my guy to get off the phone, I did a quick check of the front steering and... the right outer tie rod is shot. So much for Mevocrap's TTX.

Anyway, at least I don't question get high on gas f

umes anymore.

Without

Easily my least favorite job that I've done on the TB. With any job in the Rust Belt you have to plan on running into headaches but it felt like every little thing wanted to be a butthole. I'm sure I had at least as many hours into getting the wheels back on the ground. More than I had into rebuilding the front end, ffs. Glad to see you got through it without murder or property destruction.Did the fuel pump on the TB. Despite having a hoist and tons of tools, took over 6 hours although the DIY shop owner was on the phone for an hour so he only charged me for 5 hours. The straps were in relatively good condition and the bolts came out with breaking or spinning in the frame. This thing then fought me on everything. Broke almost all the line clips, the fuel line was rusted to the pump so had to fiddle with the plastic spacer that goes in it, the filler hose was just being a PITA and the old lock ring wouldn't budge, even with an air hammer (albeit a weak cheap one) but it eventually came off. Hell, even the old pump wouldn't come out as it somehow expanded and wouldn't fit through the hole. I wasn't gentle anymore.

Getting the new lock ring on was no picnic neither. It just wouldn't turn all the way. Had to bend the tank's tangs back a tiny bit to allow the ring to go to full lock. Then more fun fixing the fuel line connector, replacing the broken clips and putting it back into place. One of the bigger clips that broke I didn't have a replacement so I used a zip tie instead. It's just an evap line so it'll be good enough. And the final fuel line connector was just being a PITA to go back in despite using some lube on it. Ran it before the final bolt up to ensure no leaks.

And while I was waiting for my guy to get off the phone, I did a quick check of the front steering and... the right outer tie rod is shot. So much for Mevocrap's TTX.

Anyway, at least I don't get high on gas fumes anymore.

View attachment 106266View attachment 106267View attachment 106268

Last edited:

Anyway, as for "what did I do to my GMT360 today" I sucessfully activated each of these Motor A & B circuits using commands from my phone and Bluetooth adapter and "adjusted" the position of my shift motor just slightly. Why do such a thing? Just to see if I could of course!

Just to satisfy my own curiosity I spent some time investgating the Tech II commands for activating encoder motor circuit A or B. My lady bought a bare bones little single channel osciloscope for a little kit radio project and I used that to have a look at the motor circuit while noodling about with the commands. I managed to figure out that the TCCM runs the motor circuit with a PWM output of from 8% (maybe 4%, I forget) to 50%. Of course I cannot say that is the entire range it uses in real-time operations but that is the range that is accepted as a device control operation by a scantool.

The Upull I go to, Colorado Springs, is hours away but the next trip I will have to grab and encoder motor to play with. I always have an assortment of items that are not needed for my vehicles but solely for my hobby of exploring these vehicles electronic modules and their operations.

I think I currently have something like 4 PCMs, 2 BCMs, 2 IPCs, 3 or 4 TCCM, 1 DDM, 1 PDM and a pair of CJ2 HVAC modules.

I may need an intervention.

Where in Colorado are you?

South Fork. Just down the hill to the east from Wolf Creek Pass and the ski area.

Wow... Thats a bit of a drive for me!South Fork. Just down the hill to the east from Wolf Creek Pass and the ski area.

Oil pressure has started fluctuating when cold. Normal idle oil pressure is 35psi but recently it has been fluctuating down as low as 10psi with idle at 550 - 600 rpm. The fluctuation is regular and happens only at idle and only when cold; after a coupe of minutes it stays steady at 35-40 psi. Graphed RPM and Oil Pressure side-by-side and confirmed steady idle while seeing pressure fluctuate. The link below captures exactly what I am observing; looks like the oil pickup seal needs replacing. Truck has 180K miles on it.

Chevy Silverado oil pressure fluctuation/low(and the fix)

Chevy Silverado oil pressure fluctuation/low(and the fix)

Just make sure it's not the sensor first. It's a well known failure part. I'd try replacing that first or do a pressure test to confirm.Oil pressure has started fluctuating when cold. Normal idle oil pressure is 35psi but recently it has been fluctuating down as low as 10psi with idle at 550 - 600 rpm. The fluctuation is regular and happens only at idle and only when cold; after a coupe of minutes it stays steady at 35-40 psi. Graphed RPM and Oil Pressure side-by-side and confirmed steady idle while seeing pressure fluctuate. The link below captures exactly what I am observing; looks like the oil pickup seal needs replacing. Truck has 180K miles on it.

Chevy Silverado oil pressure fluctuation/low(and the fix)

Took the TB out for a quick grocery store run and I was greeted with the familiar smell and Exxon Valdez slick. And it also takes longer to start so fuel pressure loss. New cuss words invented.

My wife drove it on Sunday and no issues then. Yesterday, the DIY owner called to check that all was good. It was until now. Maybe it's the front connector because I did have a hard time getting it in. The tank is full of gas. I might try to pump it out tomorrow just in case we have to drop the tank again. Will get connector repair kits just in case. Probably won't be able to get it in the shop until next week. Might get that outer tie rod done at the same time.

FOOK!

Oil pressure has started fluctuating when cold. Normal idle oil pressure is 35psi but recently it has been fluctuating down as low as 10psi with idle at 550 - 600 rpm. The fluctuation is regular and happens only at idle and only when cold; after a coupe of minutes it stays steady at 35-40 psi. Graphed RPM and Oil Pressure side-by-side and confirmed steady idle while seeing pressure fluctuate. The link below captures exactly what I am observing; looks like the oil pickup seal needs replacing. Truck has 180K miles on it.

Chevy Silverado oil pressure fluctuation/low(and the fix)

What sort of cold temps are we speaking of here??

"Cold" in Tempe, AZ is obviously a relative term; mid-40's at night.What sort of cold temps are we speaking of here??

"Cold" in Tempe, AZ is obviously a relative term; mid-40's at night.

Ahhhh, I have what I deduce is a pickup tube O-ring leak on my 2002 4.2 LL8 but it only surfaces below say 20°F at the first startup after a nights off cycle, and then again at an oil temperature above 195°F.

Similar situation here, happens on first start of the day. Haven't monitored oil temp in parallel with oil pressure. Will do that tomorrow to see where the fluctuation ceases.

Edit: Cannot find a PID for Oil Temp. Outstanding video on the replacement process here:

Chevy Silverado Oil Pan Gasket Replacement How-To

Edit: Cannot find a PID for Oil Temp. Outstanding video on the replacement process here:

Chevy Silverado Oil Pan Gasket Replacement How-To

Last edited:

Good news! I won't have to drain the tank.

Bad news:

And that's not even a connector I touched. It's more forward above the transfer case. Leaking that much, I can't even drive it to the shop. I'll probably get CAA to tow it over there (they do owe me a 200km tow this year). Looking at the video again, it may be the metal line it connects to.

FOOK!

Bad news:

And that's not even a connector I touched. It's more forward above the transfer case. Leaking that much, I can't even drive it to the shop. I'll probably get CAA to tow it over there (they do owe me a 200km tow this year). Looking at the video again, it may be the metal line it connects to.

FOOK!

BrianF

Member

Hopefully the leak is accessible, I just got triggered from my fuel line clip saga whenever the hell that was.

F00000000000000000000000K :/Good news! I won't have to drain the tank.

Bad news:

And that's not even a connector I touched. It's more forward above the transfer case. Leaking that much, I can't even drive it to the shop. I'll probably get CAA to tow it over there (they do owe me a 200km tow this year). Looking at the video again, it may be the metal line it connects to.

FOOK!

Ordered a Dorman fuel line that goes from the fuel rail to the tank. Seems to be the easiest and best solution however will take a couple of weeks to get here (they were backordered here)

Thanks bubba, Imma have to break out the stethoscope tomorrow, I just spent the *yogic stillness* cutting the slices of light into a white plastic chip beside the flywheel, absolute center of absolute zenith has beeeeeeeeeen CUT!!!!!! Even though this engine's all 'sploded and I could get down on the crank cradle and go through the rings, the time *hath come* that this sweet ship must set sail.I would be placing a hamd lightly here or there while waiting for the "ping" to see if anything could be felt.

I'm bankin' once pre prime first flow force feed oil PSI comes back downtown, everybody in the case that needs freshly forced *AHNAHLD SCHVAZZANAGAH ROYAL PURPLE PUMP UP* gonna get with it. The *CLACK* sound -*sounds like* loudly clicking a tongue against the roof of a mouth. No plugs, no coolant, everything's naked. Just valve train & rings in the house. I'll have to take a vid and see if I catch *THE PHENOMENA*

Replaced the oil pickup tube O-ring & oil pan gasket. The old O-ring (original w/ 180K miles) clearly shows signs of deformation/flattening. Oil pressure is no longer fluctuating at first startup; also, now running 3-5 psi higher. Have to say, this involved a fair amount of dis-assembly & re-assembly just to be able to get at a part that retails for $1.81 on RA.

@azswiss Do you have 4x4 transfer case pulling requirements on that operation too? *Talk About ^^^intensive^^^ for those gaskets. I feel like it would have been *STELLAR* to have some good old fashioned replaceable vulcanized stamp gaskets made for the platform pan/fc. The glue/de-glue kinda cuts out the "racing" mechanic aspect consideration!! lololol