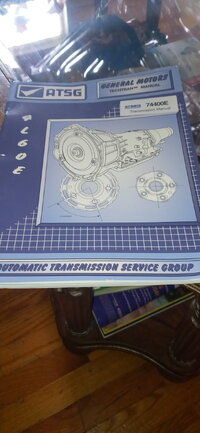

trans bench guy did say to prevent a common dtc code (4got the number 1870 or 1070 something70)to ream the bore for and replace the converter clutch valve..the reamer is 100plus and the new valve cost around 50..so not gonna do that..

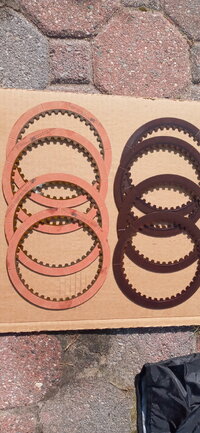

This is actually really important, without it there is leakage or "blowby" of fluid past the piston in the worn cylinder, this causes the overall pressure to drop which means the clutches and band don't have full pressure and they start to slip and burn. It would be a shame to rebuild everything you've done so far and not fix the problem that caused it all in the first place.

There are two fixes for that worn valve, one is the reamer and inserts from Sonnax to restore them to OEM operation of PWM lockups of the torque converter. When the PWM works you don't feel the tourque converter locking. I think the other fix is by Transgo, it's a lot cheaper, no tools required you just change some springs and install their new piston and it holds pressure but you lose the PWM function and the lockup feels like a shift when it happens.

If your cash is wearing thin or you just don't want to spend the $$ on a one time use tool then at least get the cheaper kit so the leak gets plugged and you're not burning all your new clutches.

..first thing to do in the morn..glad i caught that now

..first thing to do in the morn..glad i caught that now