I'm no expert, I'm just following along and watching vids like you but...

Try taking a pressure reading before you take it out. I'm not 100% sure how to do it but I remember seeing a vid where there was a place to put a pressure gauge to see what the internal pressure is.

If there is no pressure from the pump nothing will work. Knowing that would allow you to concentrate on the pump and leave the rest of the gears/clutch packs alone.

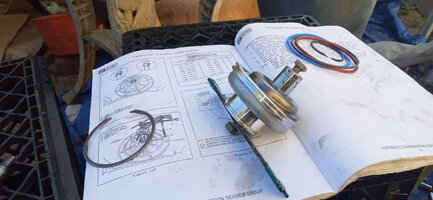

Didn't you end up with an extra seal or o-ring on the pump rebuild?

If there is pressure then you can ignore the pump and look for a reason why the clutch packs aren't engaging.

My bet is on the pump since all gears including reverse are out.

On the bright side... - aren't you glad you put that drain plug in!

A note for the cable, I undid the nut on the end of the shaft and dropped the entire cable adjustment assembly. The shaft has a flat spot so it goes back indexed to where it was. This saves playing around with that adjustment.

I feel your pain, I've had to pull things twice before and pulling it the second time is rough but it's fresh in your mind and will go a lot faster this time.