gmcman

Member

- Joined

- Dec 12, 2011

- Posts

- 4,681

For the taps in every gear, is the vehicle stationary and you are selecting each gear, or are you driving it? If stationary, you should only have 1st engaged when in 1-3-D, and 2nd engaged if in 2.

Are the torque converter bolts tight?

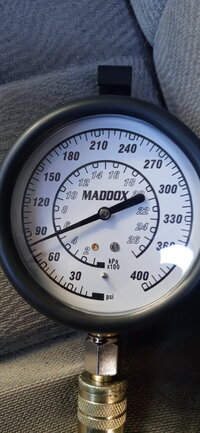

How long did the engine run before you shut it down? Are you sure the pump is getting fluid? I agree a pressure test would tell a lot.

I don't know the protocol for the 1st run on a rebuilt trans, but I would suspect raising the rear wheels off the ground and let everything turn slowly under minimal load.

Are the torque converter bolts tight?

How long did the engine run before you shut it down? Are you sure the pump is getting fluid? I agree a pressure test would tell a lot.

I don't know the protocol for the 1st run on a rebuilt trans, but I would suspect raising the rear wheels off the ground and let everything turn slowly under minimal load.