Mike534x

Member

- Apr 9, 2012

- 1,003

That is correct! I'll check the kit to see if the appropriate fitting/adapter is in there. So at minimum, the pressure should be 12 PSI at just idle. I don't know for sure if the pick up tube is blocked, but the oil on the dipstick is relatively clean with the 1500 miles on the oil change done via dealer in Oct (prior to purchasing the truck). No hint of gas in the oil from the smell test either.

I am curious on why the dummy gauge wasn't reading 40 PSI with the switch disconnected, because from past readings the gauge should at the very least give the false reading then?

Cleaning the TB is definitely on the list, I wanted to remove the coil packs and inspect the spark plugs to see if a tune up was ever done, and whether the correct plugs were used. I've got Iridiums on hand, so it'll line up perfectly this weekend when working on her. I'm half tempted to pull the VVT solenoid to inspect the screen, to see if it looks like there's any blockage/gunk clogging it or if the screens are missing like most of them are prone to with age.

I am curious on why the dummy gauge wasn't reading 40 PSI with the switch disconnected, because from past readings the gauge should at the very least give the false reading then?

Cleaning the TB is definitely on the list, I wanted to remove the coil packs and inspect the spark plugs to see if a tune up was ever done, and whether the correct plugs were used. I've got Iridiums on hand, so it'll line up perfectly this weekend when working on her. I'm half tempted to pull the VVT solenoid to inspect the screen, to see if it looks like there's any blockage/gunk clogging it or if the screens are missing like most of them are prone to with age.

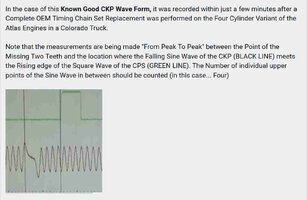

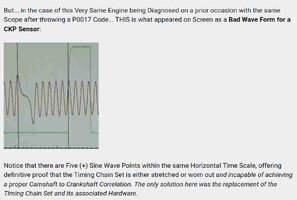

I'm having issues with a code p0017 and I have to get it fixed before I have to go in for the annual state inspection.

I'm having issues with a code p0017 and I have to get it fixed before I have to go in for the annual state inspection.

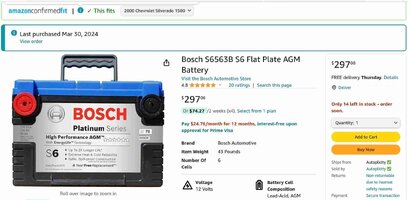

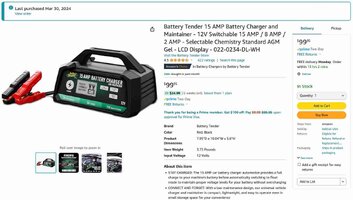

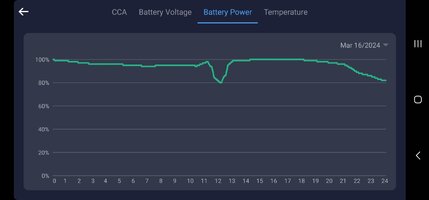

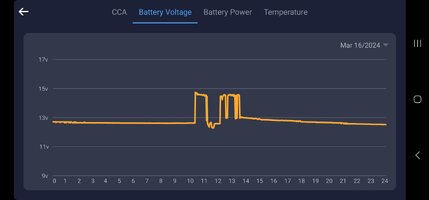

When I looked at the time readout, I thought that was minutes, and you meant that was your whole drive. Oops. My battery monitor shows the time stamps along the bottom, so I misread your voltage chart.

When I looked at the time readout, I thought that was minutes, and you meant that was your whole drive. Oops. My battery monitor shows the time stamps along the bottom, so I misread your voltage chart.