Around September 27th, 2022, Hurricane IAN Blew through along the Gulf Coast of Florida and the upper 20 Feet of a 100 Foot Tall Rotting Pine Tree in my Neighbor's Yard leaning over my Back Fence broke off in the powerful south to northbound gusting wind vector and struck the outer roof and rain gutter of my Back Porch causing some damage:

I later brought this to the attention of my Millionaire Neighbor's Grounds Keeper and

he Swore on the Souls of his Children that he would

"Have that Tree taken down." He did nothing. But you see... my Rich Neighbor is a Quadriplegic who has had enough grief in his life to worry about, so I decided that when the time was right, I'd have that tree removed, along with all of the Big Overgrowth on my property, including *tuning up* the Large Oak Tree

(think... "Sleepy Hollow" Scary looking here) threatening to damage the front roof area of my residence.

So a few weeks ago... Enter the "Sherwood Tree Service", a Licensed and Insured Genuine Arborist and the Owner Tom and his Intrepid Crew soon worked tirelessly over a two day stretch while being pelted with Icy Rain and while climbing these tall, slippery trees so very precariously at times that at one point,

I asked them to stop before anyone got hurt.

They smiled and to a man said,

"MRRSM... We do THIS Stuff ALL The Time..." When the work was finished...My Huge Oak Tree was damned near "A Work of Arboreal Art". This was an amazing outcome considering they were charging about half as much as the many other estimates from Tom's competition. When the huge job was completed, I insisted on adding in a very considerable Bonus for the Crew because of the Terrible Hazards they overcame while laboring so earnestly on my behalf.

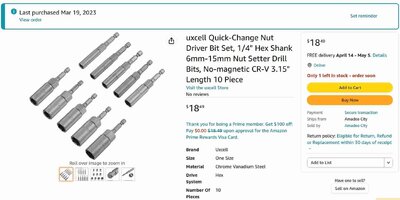

And that leads to "The Tools" featured in this post as a

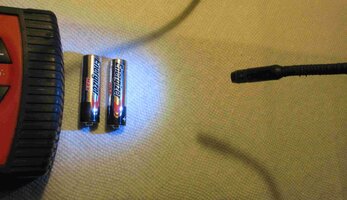

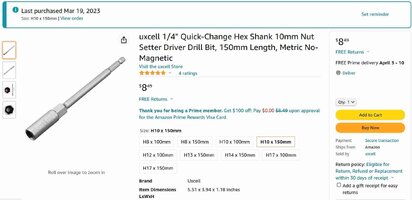

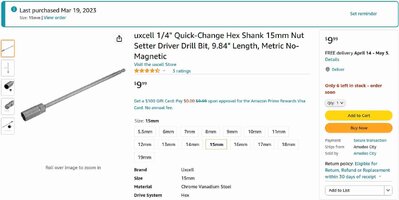

Milwaukee 1/2" M18 FUEL Brush-less Hand Hammer-Drill capable of turning both of the

Brand New 12" X 1" and 18" X 1/2" "Ship's Augers" necessary to drill deep into the Tree Stumps that I definitely wanted

Killed Off. In most Horror Stories involving putting down Dracula, the Tool of Choice is

NOT Holy Water and a Silver Cross of Christ...but instead...

A Humble Wooden Stake driven straight through the Vampire's Heart. The same can be said for Killing Stumps..."

DRT".... (Dead...Right THERE...) but the "Stakes" needed here are

Pure Copper Nails.

A few years back, one of my Other Neighbors... not so affectionately known to all as "Wacko-One" (draw your own conclusions) sported a

HUGE and imposing Pine Tree that was decorating her neighbors Vehicles with Pine Sap. The outcome was that for some strange reason...

THAT Giant Pine Tree wound up being "DRT" almost overnight.

And as the rumors would have it... The Tree Surgeons working on the Removal Job damaged the Power Saws they were using after accidentally running them over some array of "Copper Spikes" with their powered blades and finding tout right then that somebody driven those Cooper Death Spike deep into the Trunk of that Big Ol' Pine Tree.

So, I've seen first hand what these

"Copper Nails" can

REALLY Do...

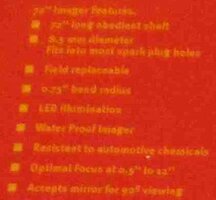

(probably due to the Copper-Oxide or Copper-Sulfate Leeching out of them inside the Xylem and Phloem). So I will be using them HERE in about a week or so after the Potassium Nitrate gets introduced. The reason I obtained several packets of them is that now that the Trees have been cut down to the ground, I want them to

STAY that way... especially those few Malignant Brazilian Pepper Trees that are dug in along my Fence Line.

To accomplish this, I first need to Drill Down

DEEP into the Hearts of the

Huge Sable Palms, Live Oaks and Florida Holly Tree Stumps and then pour in a

LOT of Potassium Nitrate via the

"Spectracide Stump Remover" Dispenser Bottle in order to desiccate the cores of the Tree Stumps and thus, invite the

Special Fungi that will move in right away "Chasing the Nitrogen" as a Fertilizer and wind up

Eating those Stumps from the Inside - Out. The Trick though is getting enough of the

*Stuff* as

deep inside the base roots as possible to make this work.

en.wikipedia.org

So I was guessing that a

1/2" Hand Hammer Drill with a LOT of Torque and Durable Battery Power along with the proper Long Wood Drill Bits-Augers would be required and thus, I am adding these to my collection of Splendid Milwaukee M18 "Fuel Tools" and Specialty Drills, hoping they will be my BFF to get all of this work done and

NOT have any New Tree Growth haunting my back yard, come Spring:

Same Day Follow Up on Monday, 11/27/2023 @ 12:50 PM EST:

AWESOME TOOL COMBINATION !!!

I used the LONG 1/2 OD "Ship's Auger" to drill the FULL 18" Deep into the bases of the Sable Palms, Live Oak and Brazilian Pepper Tree Bases... and with Two Fully Charged M-18 Batteries at hand...

THAT Drill went all the way in

LIKE Butter. The holes were drilled in a stellate pattern around their "hearts" and then I filled each one with 18" X 1/2" DEEP of the Spectracide Potassium Nitrate Powder.

It only took about 30 Minutes to do Two Sable Palms, One Live Oak and Three Florida Holly (Brazilian Pepper) Tree bases. It helps to stop occasionally to allow the Milwaukee Drill to

*Cool Down* just a 'BIT' and to extract any root and trunk fiber windings from the coring Drill Flutes as often as they build up...

But other than THAT... This Ideal-Tool-Combination worked out swimmingly well.

I could NOT be Happier if I was TWINS!

not fun helicoiling a 1000$ crank...

not fun helicoiling a 1000$ crank...