As mentioned here, and in other threads, I've been curious about pneumatic floor jacks. I've seen the air assisted, hydraulic bottle jack style which are usually 12 or 20 tons, but too tall to get under the front of our trucks. Came across the air bag style. They're a dime a dozen on Ebay and Amazon, with varying degrees of positive/negative reviews. My main thing was to find one with some kinda warranty in case I got a dud. For the longest, many were being priced right around $100, but right before Thanksgiving the prices started going up.

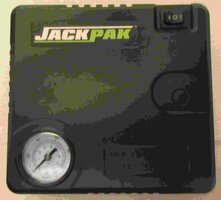

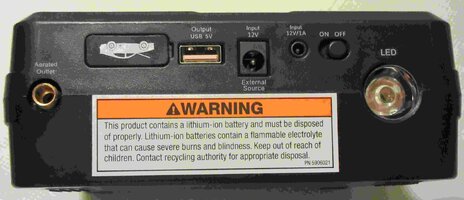

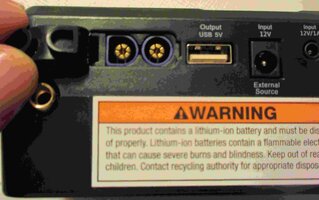

Found this one with a listed 1 year warranty, and pulled the trigger. FedEx dropped it off this afternoon. Here it is unboxed, and then assembled. Conveniently, it stands up on end for space saving storage.

We've often referred to stuff bought online as cheap Chinese crap... Well at least I know, this ain't that!

Now to the business end. I knew ahead of time, this wasn't going to provide as much vertical lift as our traditional hydraulic jacks. Max height is about 12". I started off trying to lift the truck by the frame at the B pillar, as expected, not enough reach, it did relax the suspension, but couldn't lift the tires off the ground. It inflates quickly and gets to max height in a couple of seconds with the inlet valve wide open. Deflation is slower and more controlled which is probably a good thing.

Went around to the rear and lifted by the diff, as expected plenty of clearance to throw a pair of jack stands under the axle. (I see I missed a spot cleaning up that tranny fluid leak from the summer

)

Came around to the front, and didn't have quite enough reach. At max height, the tires are barely touching the floor... So I'd have to lift from the control arm

My idea was, since the base is just a flat piece of sheet metal, build a riser out of some spare 2x4s to give it a boost, maybe about 4-6". When the bag is fully inflated, it does flex and lean a bit depending on how centered your lift point is on the cradle, so not having to go max height would be good stability wise.

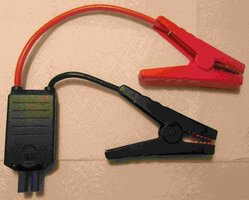

One consistent complaint I saw in many of the reviews, is the air line fitting that comes with it, is some funky unknown size, other than your typical 1/4. In some ads, the sellers swapped in the right fitting, this one wasn't the case. I have spares so not an issue. The oddball fitting is on the right.

It uses a pair of ball valves for the inlet and outlet. I read of some buyers swapping these out for trigger style valves, and I think that's the route I'm gonna take as well. Only got to use it for messing around so far, but I like it. Much easier to make height adjustments, raise it a little here, drop it just a touch there with a quick reach and twist. That's convenient for me, since my knees like to complain if I get up off the ground a number of times. That's usually the case trying to get the cradle positioned where I want it prior to lifting, with my other jack. It's gonna get its fair share of use over the next few weeks, so I'll be able to give a better review.

)

)

Perfect for lifting the front end. It did sag a little bit under the weight but it held up fine. And due to the casters, similarly to our hydraulic floor jacks, when the load shifted, it rolled along with it, keeping the bag vertical and no tilting.

Perfect for lifting the front end. It did sag a little bit under the weight but it held up fine. And due to the casters, similarly to our hydraulic floor jacks, when the load shifted, it rolled along with it, keeping the bag vertical and no tilting. The uppers aren't pressed all that tight. The lowers sucked on mine.

The uppers aren't pressed all that tight. The lowers sucked on mine.

)

)