Freelance_lumberjack

Member

In another thread there has been a handful of comments regarding Torque Pro and transmission parameters. Thought I would toss out a couple of things I wonder about here.

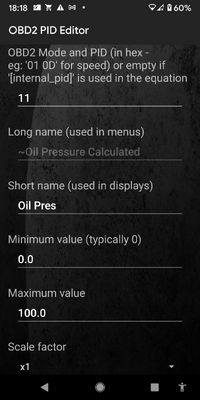

Torque Pro has their set of extended parameters that I have long surmised initially came from user submissions. What vehicles these users were testing on we will never know. So some PIDs work on our platform and some do not. For trans fluid temp there are 2 where the only difference is the header (one is for CANBUS vehicles).

Some appear to work but how reliable are they?

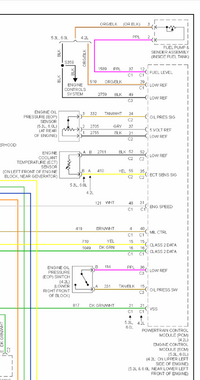

Take the PID for input shaft speed,... according to wiring diagrams my 2002 has no input shaft speed sensor so what is the source of this value??

Similarly there is the PID for TCC Slip... With no input shaft speed sensor how can this be determined and differentiated from some other component slippage??

2001 truck 5.3 4l60e pid 1973 works as a tow haul indicator. Fully tested.Do you know what PCM your vehicle is using? I really don't know doodly squat about this PCM vs that PCM but if it were the same as one I have there is at least some expectation that PIDs just might be the same.

My Trailblazer has no tow/haul mode (don't know if any of them do?) but my Yukon does.

This discussion of Tow/Haul mode... I had to go back in this thread to even see what I had been doing as with many such things I get into it for a time then move on and forget about it! So I see that I never did come to any conclusions about this 1973 PIDs bit 0 validity.

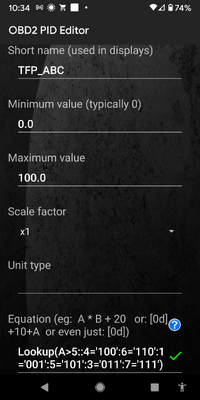

@jawhnny what response were you seeing for the 1973 PID? Did you try the PID test button in the equation editor and see the complete response or were you only looking at a Torque Pro dashboard display?

However I understand it may not for others.

There are 5 modes in the tables.My Jimmy is using a P59 I believe

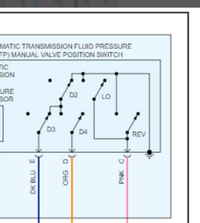

Mine never had a Tow/Haul button either but I did see it say it would use that shift table if commanded by the TCCM if it if shifted into 4lo.

I also saw I could enable a setting in TunerPro to enable it by a momentary ground to pin 71 on the PCM instead of just the TCCM data bus signal.

Works like a charm now, thank you!!

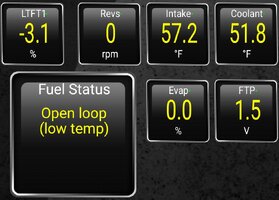

To me it seems it just switches to tell you its NOT in normal trans mode.

When I looked through TunerPro, it showed 4 tranny modes. Normal, performance/tow, manual and WOT modes. If any of these other modes are enabled, it seems to trigger this.

Works perfect to tell me if my Tow/Haul button works when I push it though.

1 Normal

2 (tow haul trucks)/competition

3 hot mode triggered by pcm

4 another one I forget

5 unused mode

Hot mode is to cool overheated trans