Hey guys, I see there is a lot of talk about pids. I added the gm extended pid set to my torque, but I still can't get wheel speed sensor data to show... Has that worked for anyone else?

Your profile lacks the year of your vehicle so I'm not sure how much of this applies.

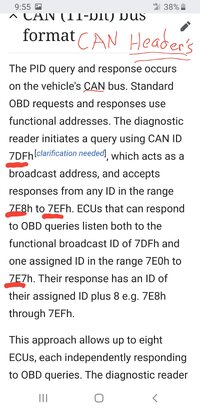

I've never seen that work in my 02 4.2 LL8. And having just looked at the format of the request Torque is sending I now know why. The request I just saw from Torque is an invalid message.

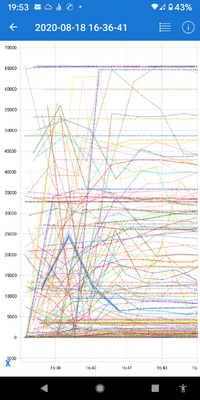

On my 05 Yukon 5.3 LM7 I get a value of one half the actual speed and the data is only received sporadically, like maybe once or twice in 5 minutes time! I need to have a peek in there to see just where that data is coming from.

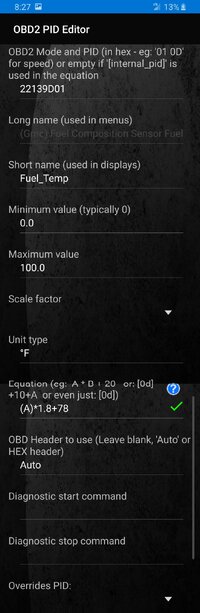

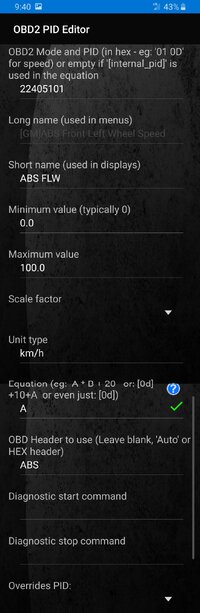

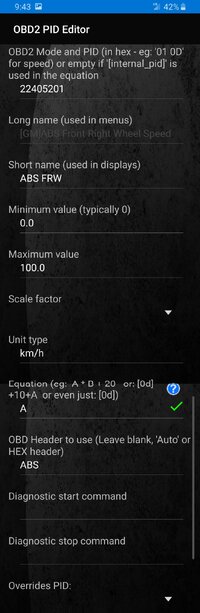

Now for some more details.... on my 02 Trailblazer the front wheel speed sensors are wired to the EBCM. The EBCM does not support service (mode) 22 parameter data requests by PID. So even if the PID #s Torque has are correct, Torque has no means of getting the data from the EBCM.

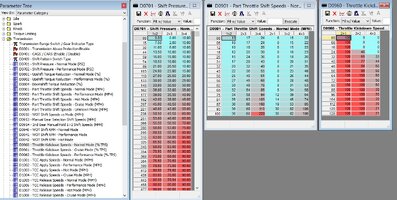

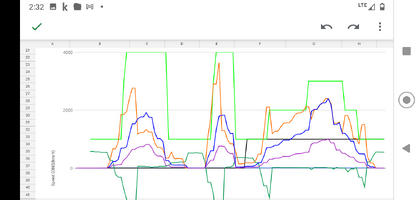

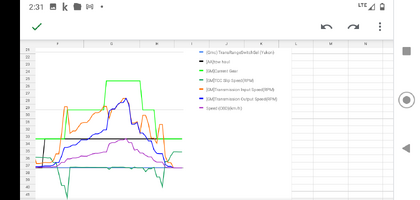

So how can a Tech 2 or other scanner be getting that data you ask! A different service (mode) is used by the Tech 2. Torque uses service 22, which makes a request for a single parameter and gets a single response. Over and over and over..... A lot of wasted time and bandwidth there. The "enable faster communications" feature in Torque can sometimes help but often the OBD adapter is not capable of that level of performance or the vehicle itself does not support that. So for faster data retrieval a scanner can use service 2A, "Request Diagnostic Data Packets". This service returns either a preconfigured packet or a packet dynamically defined by the use of other services like service 2C, "Dynamically Define Data Packet". The EBCM on my 02 TrailBlazer has predefined data packets. Packet 01 contains wheel speeds, one for each front and a single speed for the rear axle. These data packets return up to 6 bytes of data at a selectable data rate and instead of getting the data one response at a time the service can stream the data.

The Torque app is not designed for the use of these other services. Nor is any other app that I am aware of. I have fiddled with attempts to do so in Torque and have had some limited success but I cannot recommend it. It confuses the heck out of Torque and frequently locks up my OBD2 adapters.

Even if I did devise a means of retrieving the data from the EBCM that is not something I would post publicly. I believe the EBCM is built the way it is for a reason. Among the vehicles systems the brakes are what I would see as perhaps the single most mission critical system. "Tinkering" with that system is likely unwise at best. Not to say that I haven't done it,, but still not something I will get into here. Last year I discovered that codes from my Yukon EBCM cannot be cleared with the vehicle in motion. I had an intermittent issue with a wheel speed sensor that kept knocking out my cruise control while on a cross country trip. I must have pulled off on at least a half dozen exit ramps, stopped, cleared the code with a service 14 message then continued on till the next occurrence.

Now I don't know diddly squat about what happens on a CANBUS system but as far as I know on our platform when the CANBUS was brought onboard in 2008 it was only the ECM amd TCM?