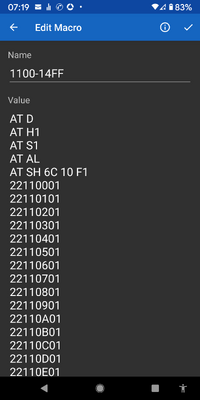

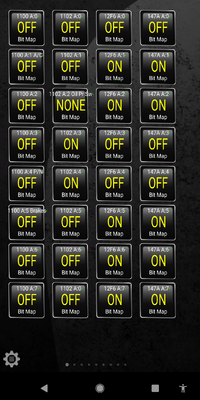

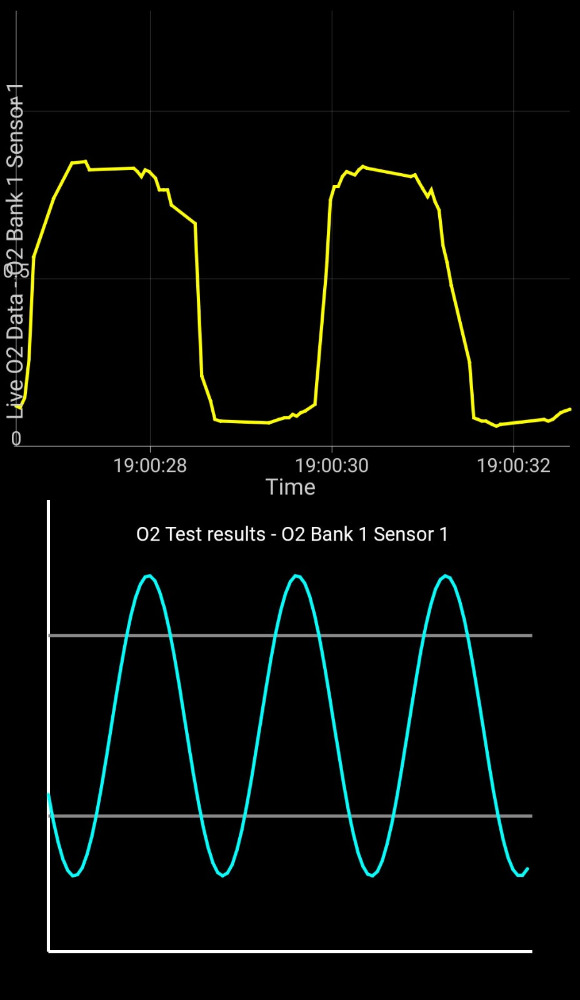

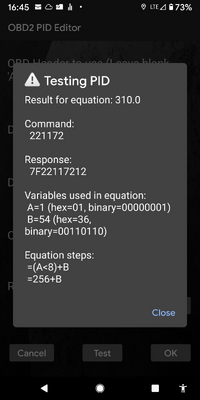

Great info. I will try the oil pressure PID you provided. I was looking at at a class 2 listing in hptuners.com forum under “PIDS” and saw that the [GM] extended pid for misfire count on cylinder 1 and 2 were swapped. I set them up with their respective history pid on the dash board and it appears that the class 2 listing I reviewed was wrong. The [GM] extended pid in Torque seems correct for their respective cylinder as the current count switches properly to the history pid. Unless the history pid is swapped as well. I will look at that tomorrow. Where you able to find any additional PIDS for the lm7? I am going to set up the TCC PIDS tomorrow and see how they go.

That same class 2 pid list listed your oil pressure address but with a different equation. Will update and see how that goes as well.

I have also read, I think it was in the class 2 forum in here that the misfire info seems unreliable and that the individual stopped even using them on the dash board. Has that been your observation as well?

Did a torque scan today and tried to email it to myself and nothing was attached and I got a note saying the proposed attachment had zero bytes. What am I doing wrong? I did the short scan as I did not have the hours it says it takes to complete.

That same class 2 pid list listed your oil pressure address but with a different equation. Will update and see how that goes as well.

I have also read, I think it was in the class 2 forum in here that the misfire info seems unreliable and that the individual stopped even using them on the dash board. Has that been your observation as well?

Did a torque scan today and tried to email it to myself and nothing was attached and I got a note saying the proposed attachment had zero bytes. What am I doing wrong? I did the short scan as I did not have the hours it says it takes to complete.