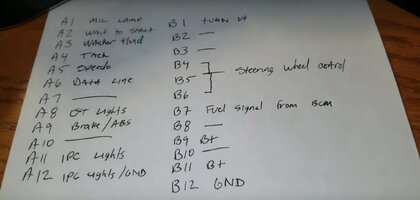

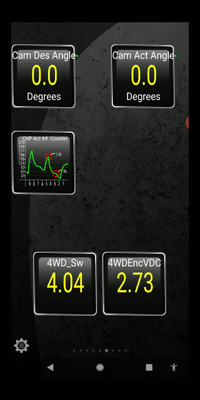

TFP Switch A/B/C. (Post #17, top left gauge) A couple of days ago I had little idea of what this was. Transmission Fluid Pressure manual valve position switch. Do what now??

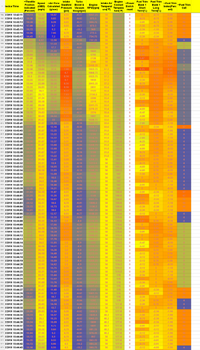

I googled the term and came up with a diagram and an understanding of the switch and its output and in working these data streams I managed to match the switch output to PID 1951, bits 5, 6, and 7, in the order A, B, and C. (Thank goodness for spreadsheets) For a display I match the decimal equivalent of these 3 bits and substitute text indicating the positions as we would see them such as Park/Neutral, Drive, Reverse and so on.

This switch cannot distinguish between Park or Neutral as the valve body pressures are the same in these 2 positions. (Or so I've read)

Could this be useful somehow? I have no idea, but I found it and it works to display the switch position, if not the individual channels of A, B, or C. This switch will not indicate changes in transmission selection without the presence of fluid pressure so if one shifts through the selections with the engine off no change is seen of course.

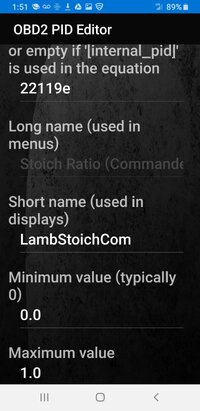

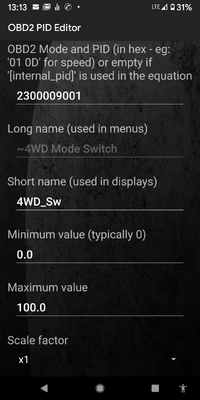

Name = Transmission Fluid Pressure Switch A/B/C

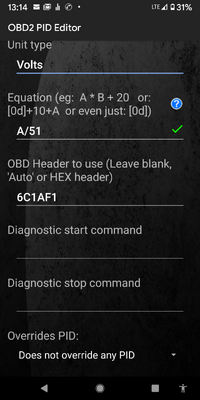

PID = 221951(append 01 for faster response in Torque)

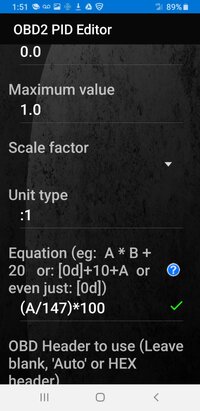

Scale = x1

Units =Bit Mapped

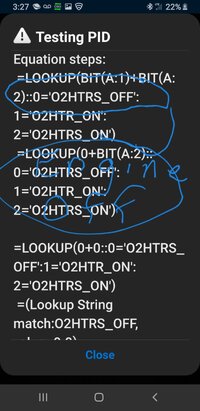

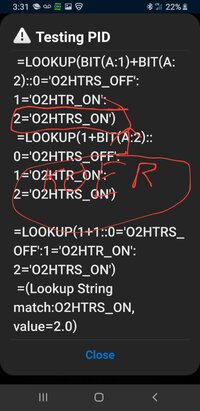

Equation = Lookup(A>5::5='P/N':4='Reverse':1='Drive':3='3rd':7='2nd':6='1st')

Header = Auto

Previously I have posted a PID for Park/Neutral as 221131, bit 2. That PID/bit does indeed indicate Park/Neutral as a value of 1 and all else as 0. That PID 221131 also contains things like crank request, starter relay command and a couple of other items I have yet to even hazard a guess. I have to remind myself that we are not in fact seeing the actual switch data. The PCM is seeing that information and outputting these PIDs that we then call up. I can only make logical guesses at where the PCM is getting its information based on testing and watching the data streams. I see that P/N as displayed by PID 221131 bit 2 changes without the engine running so it is not a derivative of the TFP switch. So where does it come from?

Transmission Range Switch A/B/C/P ?? (Post #17, center left gauge) Again I say "Do what now?" More tests, more googling, more noodling around and I find this switch is also represented in PID 1951 as bits 0,1,2, and 3. It has 4 switch outputs and through combinations represent all positions including separate park and neutral indications. I believe this to be a switch on the drivers side of the transmission. Since this has separate park and neutral indications it doesn't look like a candidate for the source of the 221131 bit 2 P/N indicator. I may never know what is that source so I will move on knowing only that it does appear to indicate P/N, if not an actual switch position. To further muddy the waters there is also a previously unmentioned PID 221920 (seen in post #17, bottom left gauge) that also displays a Transmission Selection with a single bit (#1 thru 7) each representing one of 7 positions, P,R,N,D,3,2,1. Confused yet?? I can tell you I am! I am currently wondering if this PID 221920 is for use by the Instrument Cluster for the display there.

Back to that Transmission Range Switch A/B/C/P.

PID = 221951( yes, this is the same PID# used above but we will be using different bits from it. And again I say "append 01 for faster response in Torque)

Scale = x1

Units = Bit Mapped

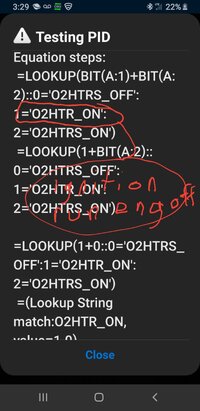

Equation = Lookup(A-(A>5)*32::6='Park':3='Reverse':10='Neutral':9='Drive':0='3rd':5='2nd':12='1st')

Header = Auto

And just for completions sake here is what I am currently using for PID 221920. I did not alter the value of A here and there exists a possibility that this will be erroneous if ever a value appears in bit #0. I have a solution for that if it comes up.

Name = Trans Select

PID = 22192001 (I have already appended the 01)

Scale = x1

Units = Bit Mapped

Equation = LOOKUP(A: :128='Park':64='Reverse':32='Nuetral':16='Drive':8='3rd':4='2nd':2='1st')

Header = Auto

Whew!!