can duplicate this even when the ac relay is removed. This leads me to think that with the relay removed the system thinks the compressor is running

Hmmmmm...

Well, there is a compressor feedback signal to the HVAC module. So that module should surely know if the compressor clutch is powered or not.

If the relay is out then the clutch cannot be powered and thus the feedback signal to the HVAC module (connector 1, terminal B12) must be absent.

So at least the HVAC module knows the compressor is not running.

While the PCM does control the actual enabling of the compressor it does so at the direction/request of the HVAC module. The PCM does not decide on its' own to engage the compressor.

With the relay in place it goes like this:

A press of the "snowflake" button while the compressor is enabled causes the HVAC module to send a message for the compressor to be disabled (8815981001 for anyone interested).

The PCM then reports the current status of the compressor (enabled) and then acknowledges the previous message from the HVAC module.

Now the HVAC module acknowledges the status report from the PCM.

Then the PCM reports the current engine torque and the disables the compressor and again reports the status, now disabled.

The HVAC module acknowledges the PCMs status report of the now disabled compressor.

The PCM again reports the current engine torque.

All this happens in maybe 200 milliseconds or thereabouts.

This is typical of the goings on of the serial data bus. Almost nothing works like the old days of control loops and active switches anymore. It's all programming and sensor inputs.

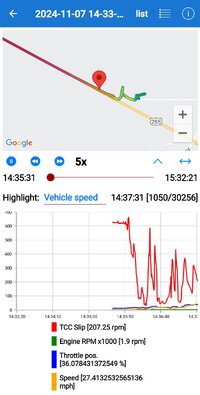

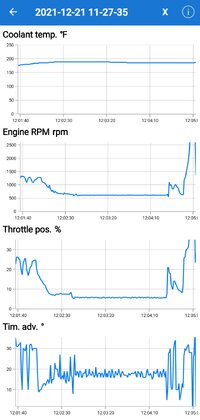

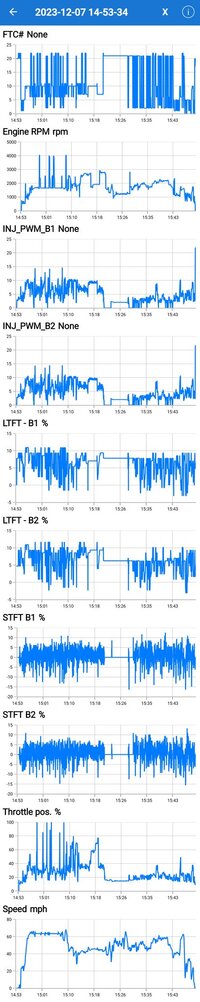

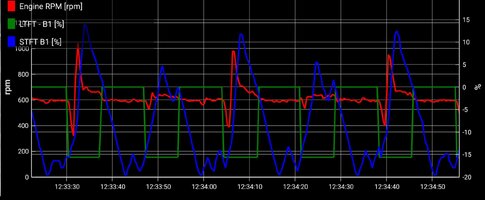

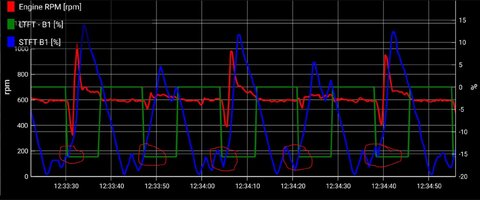

We know the PCM adapts the idle to compensate for the load of the compressor.

So when the compressor is stopped what adjustments are removed?

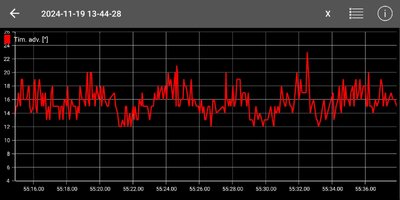

I am curious about what happens with the throttle angle, injector pulse width, and other parameters the PCM may adjust in anticipation of the release of the compressor load.

It's too cold here for me to attempt any tests with my own 2002 4.2. Mid-teens °F each night and tomorrow's high is forecast at 29°F.