Sqrly

Member

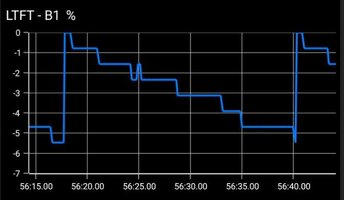

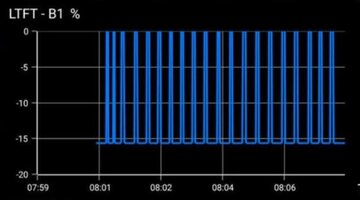

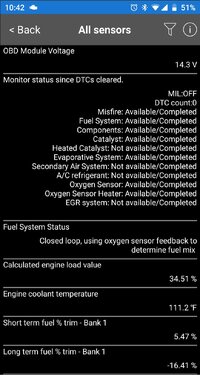

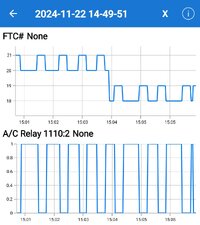

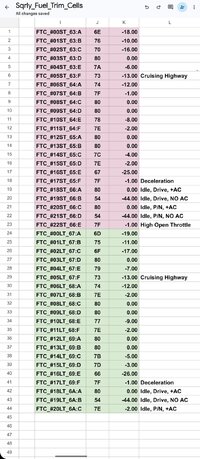

The capture is good and as expected for a hot idle vehicle. Your "observed" LTFT is the problem.... no way it should be sitting in that far negative. In fact, when the STFT swings negative, the sum is almost at coding (-25%)... running too rich.

So what could make it idle rich? Is there something to find with my scanner app?

I checked the pressure regulator vacuum line, there's no gas in it, not even the smell. The air filter was changed in march. I put in a stock one.

When I fixed the gas tank, because the cracked/leaking rollover valve had been replaced with a giant hose barb that was still leaking, I checked the charcol canister and it was dry.

I haven't changed the fuel filter yet, could a dirty one cause an issue like this?

Note: Same log as in post #78

Last edited: