Is the cell I don't see (#21LT) included in the 8 your referring to?

Should there be a #22LT?

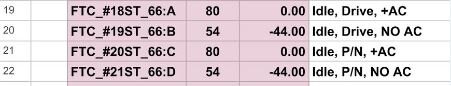

So for whatever reason, GM seems to have decided there would be no saved values for Long Term Fuel Trim Cells #21 and #22.

They are just not there with the other saved values.

Cell #21 appears to be used only at idle, in Park or Neutral, with the A/C compressor OFF.

Cell #22 I see in use only at large throttle openings, like when near Wide Open Throttle. Likely coinciding with a low vacuum, high MAP sensor reading.

Here is what I see in both recorded data and very specific tests I have recently done.

As you operate the vehicle the PCM looks at operating conditions and according to criteria set forth in the programming selects a given "Fuel Trim Cell#" to operate under.

During operation in the selected cell# the PCM begins with the stored values of the selected cell# and adds in the data it sees from the oxygen sensor to determine the fueling needs.

As it operates in the selected cell if the O2 sensor data indicates corrections are needed, at some point the PCM updates the value in the cell# in use. I have seen both short and long term cell values updated during a drive.

As operating conditions change a new cell# will become the "Current Fuel Trim Cell#" and again the PCM will switch to the stored values for that cell# and add in the corrections from the O2 sensor to determine fueling needs.

Again, if the O2 sensor indicates continuing adjustments are necessary the PCM will update the stored values for the now current Fuel Trim Cell#.

In this way when the operating conditions return the PCM back to a previously used Fuel Trim Cell# the values it then reads from the stored cell(s) will be the values it had updated when it was last there. Continuity for those operating conditions.

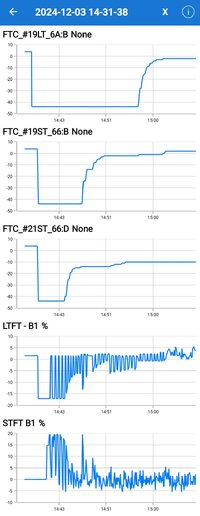

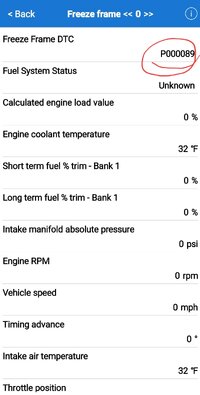

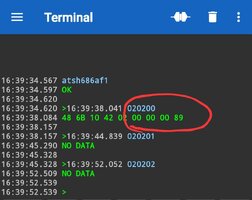

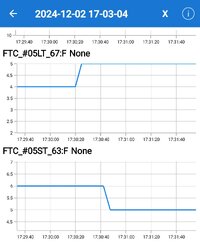

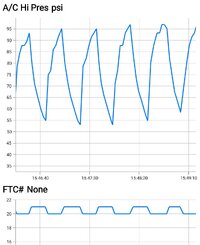

This seems like a good time for a graphic:

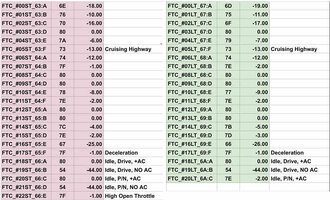

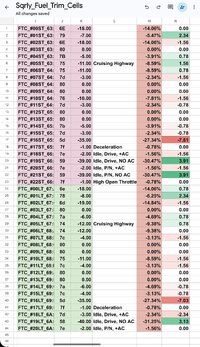

What is seen here is the values stored in all those fuel trim cells plus the "Current Fuel Trim Cell#".

The red line starting at the top left at a value of "21" is the Current Fuel Trim Cell ## in use.

The engine has recently started and is at idle. The A/C compressor is OFF.

All the graph lines below are steady, no changes so the fueling seems pretty good.

Now the Current Fuel Trim Cell# switches to #20 because the A/C compressor has started.

Again, the fueling seems OK as we see no changes in the fuel trim cells represented directly below.

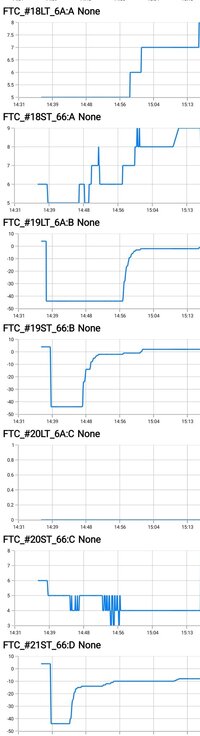

Continuing along the top red line (Current Fuel Trim Cell#) we see a drop from 20 to 18. This is when I shifted from Park to Drive. The A/C compressor is still ON and we are still at idle.

Look below this point and we see a line has begun a rather sharp increase in value. In was at 5 and rose to 12 in about 20 seconds. The PCM has seen O2 sensor data indicating the mixture was lean and in response increased the fuel trim value and updated the stored value for this cell# as well.

Just about the time the rising value reached 12 the Current Fuel Trim Cell# (red line up top) changed from 18 to 19. This is when the A/C compressor turned OFF.

Since we are now operating in a different cell# we see a different line down a little lower starts it own rise. The PCM is seeing a lean mixture condition here in this cell also and has increased fuel trims there as well. This cell begins at 2 and rises to 5 before the "Current Fuel Trim Cell#" changes yet again. This time to Fuel Trim Cell# 0.

And so it goes, the operating conditions cause a given cell# to be selected as the Current Cell in use and the PCM starts with the values previously stored in the cell and adjusts and updates the fueling and stored values as needed.

I avoided stating that these cell values we saw being updated were Short or Long Term values. Either can and will be updated as seen fit by the PCM programming. The cells we saw updated were Short Term values.

Now then, at the end of your drive you turn off the key. At the moment the key turns from RUN to ACC The PCM updates at least some of the stored Long Term Cell values, presumably incorporating data it obtained during the drive.

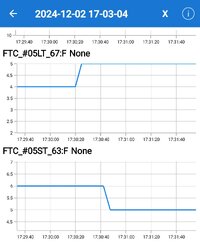

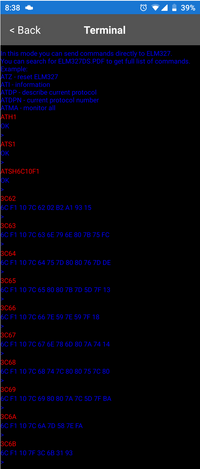

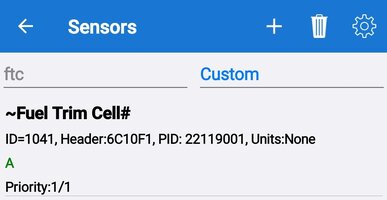

Shortly after the Long Term Cell values are updated the Short Term Cell values essentially copy the Long Term values of the same cell##. Often the copy is the very same value though sometimes I see the value increased by no more than 1. So far I have not yet seen or recorded any time when the copied value is decreased at all. Here is an example where the key was just turned from RUN to ACC and Long Term Cell #5 is updated from 4 to 5 and then copied to Short Term Cell #5.

The result of this is that at the next startup The Long and Short Term Cell values will be about the same, or no more than a single bit different.

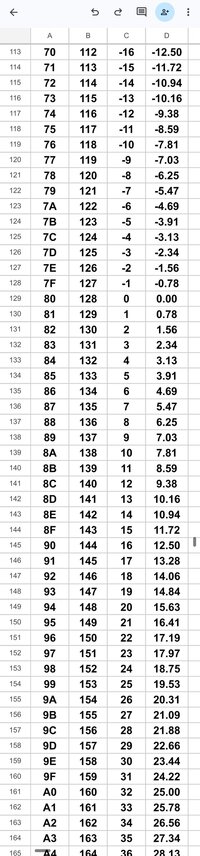

You can see this in your own cell values I have posted in the spreadsheet screenshot previously. Between Long and Short Term values they vary by no more than 1 and where there is a difference the Short Term is always more positive than the Long Term.

So you may be asking "What about Cells #21 and #22 where there is no Long Term Value to copy from?".

It gets weird there. Tests and recorded data show me that the value copied to Short Term Cells #20 , #21 and #22 come from Long Term Cells #18, #19 and #20 !!

I proved this by writing unique values to every cell, reading all the cells, then turning the key to ACC then reading back the cell values.

This is how changing just 3 cells values ends up changing 8 cells in the end.

It took me quite some time to get this straight.

I can spend days studying this stuff.

I can spend days studying this stuff.

I just used the one in the torque either the base one or the GM added ones. There is two if I recall "absolute" and "actual". As you, the "magician" knows, torque equations might be "airy" ... as in "errory"... but I would expect "standard equations" to be correct and only the sensors that are reflected in said equations to be the problem. Hence, I would find that a "wacky load" is an indication of sensor issue. My reads on the "load" pids are basically only have MAP and IAT involved. Having said that, I am sure each maker has their own "adjustments" to "help" things.... such as throttle and coolant temp. Again, this is for the "speed density" fueling system.

I just used the one in the torque either the base one or the GM added ones. There is two if I recall "absolute" and "actual". As you, the "magician" knows, torque equations might be "airy" ... as in "errory"... but I would expect "standard equations" to be correct and only the sensors that are reflected in said equations to be the problem. Hence, I would find that a "wacky load" is an indication of sensor issue. My reads on the "load" pids are basically only have MAP and IAT involved. Having said that, I am sure each maker has their own "adjustments" to "help" things.... such as throttle and coolant temp. Again, this is for the "speed density" fueling system.