BrianF

Member

Got the Trailblazer back from the shop. AC system held pressure but they added dye anyways in case of a slow leak. They recharged it and she blows cold..... very cold, uncomfortable in fact. I had jumped the low pressure switch previous and compressor did not kick on, so I figured worse. Oh well.

They found the same things as myself on the ABS module issue. Power to the unit, good ground, battery tested good. Either the ignition switch (unlikely as it was swapped when the problem first popped up) or the module itself is bad.

They found the same things as myself on the ABS module issue. Power to the unit, good ground, battery tested good. Either the ignition switch (unlikely as it was swapped when the problem first popped up) or the module itself is bad.

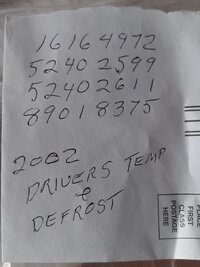

) and took apart the lower dash. Getting in there was a bitch as I'm not as flexible as I used to be (not that I was very flexible to be begin with

) and took apart the lower dash. Getting in there was a bitch as I'm not as flexible as I used to be (not that I was very flexible to be begin with  ). So get the actuator out, open it up and it looked fine, no broken gears or anything. Put in the chinesium actuator, do the relearn via the Tech2. Went through it but it was still on defrost. Huh? Thought maybe it's the other actuator, the one with the gear. Pull it out and confirm that it's for the floor and vents. Put it back in and now the vents don't work

). So get the actuator out, open it up and it looked fine, no broken gears or anything. Put in the chinesium actuator, do the relearn via the Tech2. Went through it but it was still on defrost. Huh? Thought maybe it's the other actuator, the one with the gear. Pull it out and confirm that it's for the floor and vents. Put it back in and now the vents don't work  . Pull it out again (by now the screws practically come out by themselves) and the actuator is all the way to one end. Maybe I didn't put it in right and it jumped the gears. Open it up and the "timing" was off as per

. Pull it out again (by now the screws practically come out by themselves) and the actuator is all the way to one end. Maybe I didn't put it in right and it jumped the gears. Open it up and the "timing" was off as per

. I think maybe on a -30c morning, it was probably all stiff and jumped a tooth.

. I think maybe on a -30c morning, it was probably all stiff and jumped a tooth.

.Only thing though, and that was also with the previous setup, I find the front shocks too soft with a lot of porpoising. Gabriel doesn't make a front shock/strut for my truck yet so I think I'll go with some Bilsteins later.

.Only thing though, and that was also with the previous setup, I find the front shocks too soft with a lot of porpoising. Gabriel doesn't make a front shock/strut for my truck yet so I think I'll go with some Bilsteins later.