I got the one from AAP (Masterforce? - the brand they use for all their kits). It was the most complete, with different parts & such. And they give you 45 days to return.

O'Really's has a 48hr policy (WTF?), and Autobone only showed the 'duckfoot' type puller that requires the dampener to have threaded holes for pulling with bolts (like a stuck brake rotor). Which GM doesn't use on the LS dampeners (or any, apparently?) But they do have the notches in the back that the Chrysler tool can use, as well as the 'lips' at the edge of the three spokes that the Spent-More tool (as Moose likes to call them) connects with. But I'm not paying $100 for a freaking tool that I'll use 1-2 times in my life.

Ironically, I did try the coupler trick you mention - threaded the forcing screw on 1/2 of the coupler, and the extension (double-threaded) bolt on the other half of it. That didn't work for me, either, and the thrust washer that came with the kit, which could've helped me, was too wide.

I don't like them either, and agree that something like a thrust washer would be optimal. But the one with the AAP kit above didn't fit (it was wider than the crank flange and extended into the balancer. I've already scored / galled the front of the flange (slightly) with the conical tips from my HF pullers (which are in various states of repair / breakage.) Thinking that I haven't ruined the crank yet, but don't want to keep pushing my luck. Internally, things are fine w/ threads, etc., and the new bolt will fit flush, as normal - no need for me to resurface the outer edge.

Thinking while writing here... I wonder if a socket of appropriate diameter would do the trick. Will try that today, along with

@littleblazer's method below, if required. Would really like to get this thing off w/o having to wait a week to do so.

I was confused for a minute...then I realized... you mean an extension bar. Probably with the smaller (socket) end to the back of the crank, and also ground into a round(er) shape, and the larger (ratchet) end that the rod supplied with the puller would go into (or maybe the puller itself, directly, with no rod between puller screw and extension bar. Did I guess right?

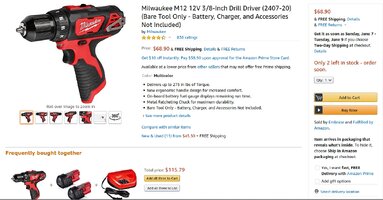

Thinking 3/8" would prolly be optimal, and maybe an impact-grade vs. chromium would be less apt to break. Thoughts? Thx.

(ok, it'll cost some gas, but it'll be good to get out of the house, and it'll keep me 'on schedule', such as it is)

(ok, it'll cost some gas, but it'll be good to get out of the house, and it'll keep me 'on schedule', such as it is)

Only about 1 -1.5 years of easy use before needing to dis-guard them. I'm going back 10- 15 years and I believe I spent about $25 each on them. I don't mind (much lol) spending good $$$ if the tools hold up. But to spend money on them and they don't last gets my knickers twisted up. Each time I use the "old regular" can opener I do think about these that don't leave a sharp edge, so I was just a wondering if yours held up better than my old pair. (hopefully you don't owe stock in either of the companies come to think of it...). Thanks.

Only about 1 -1.5 years of easy use before needing to dis-guard them. I'm going back 10- 15 years and I believe I spent about $25 each on them. I don't mind (much lol) spending good $$$ if the tools hold up. But to spend money on them and they don't last gets my knickers twisted up. Each time I use the "old regular" can opener I do think about these that don't leave a sharp edge, so I was just a wondering if yours held up better than my old pair. (hopefully you don't owe stock in either of the companies come to think of it...). Thanks.

not fun helicoiling a 1000$ crank...

not fun helicoiling a 1000$ crank...

Now if only I had enough patience to paint the heads on all the bolts... Would take a week or more having to just do a couple at a time when I had time and as mentioned, I don't have that kind of patience.

Now if only I had enough patience to paint the heads on all the bolts... Would take a week or more having to just do a couple at a time when I had time and as mentioned, I don't have that kind of patience.

(OUCH!)

(OUCH!)