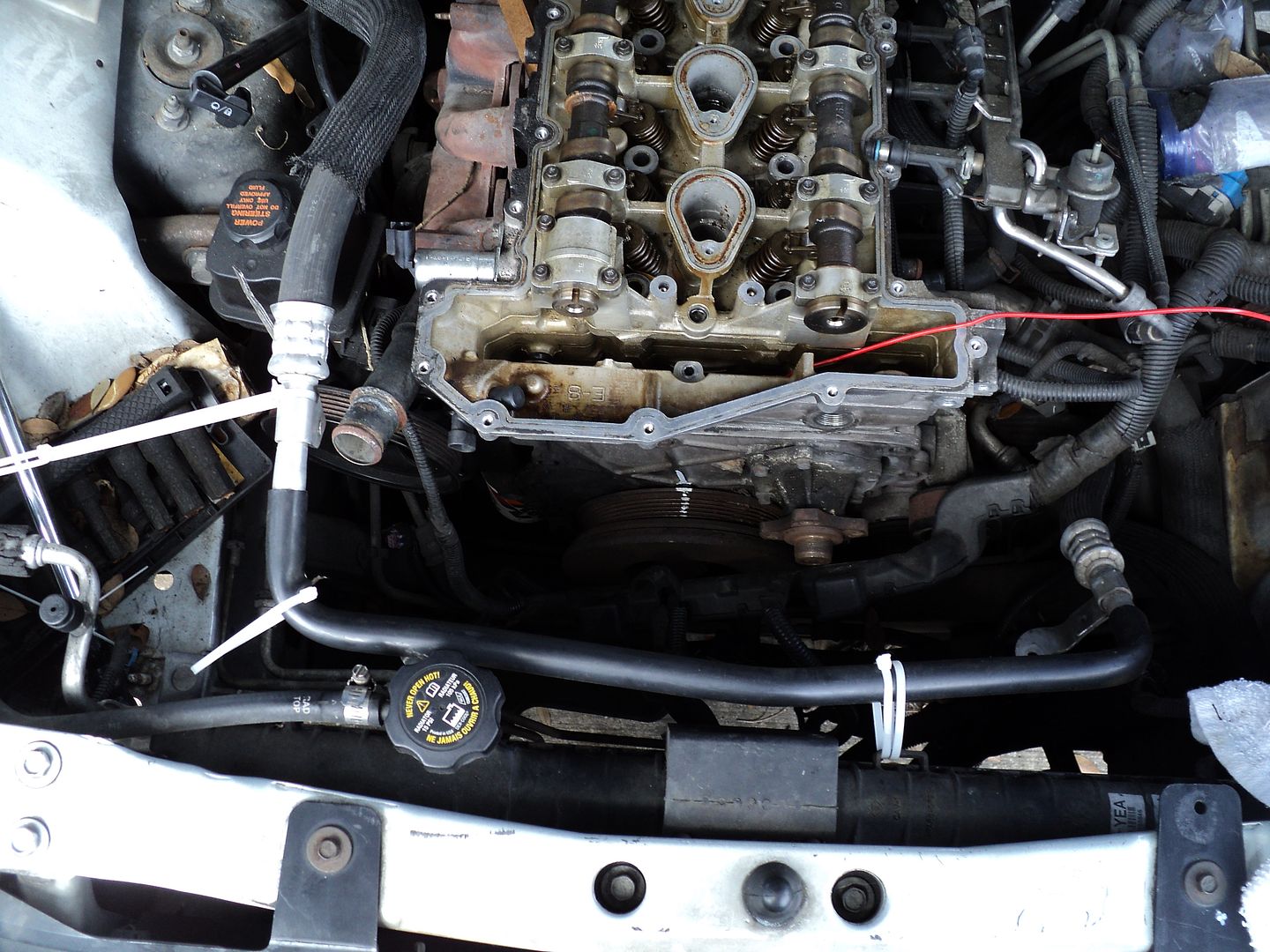

I have just managed to solve this “Not-So-Funny” Metric Bolt Sizing Question for the GM Atlas 4.2L Engine, albeit in a kind of a “Funny” way... only because “Mr. Smarty-Pants”...(..errr ..that would be YOURS...TRULY...of course) should have realized the solution to this question all along. But like so may of us who can develop “Project Fatigue”; what with our noses pressed down so close to the road we are working on... that from time to time... we can manage to lose our way with realizing we're lost.

In this case... the answer to the question mentioned above came to me all of a sudden when I realized that at some point in the last five months...I had read an interesting Technical Article concerning the GM introduction and regular use of TTY Bolts as their Standard Fasteners, specifically addressing the problems being encountered with Head Bolts easily snapping off during repairs at both ends of the work when dis-assembly and/or re-assembly of the GM Atlas 4.2l Engine became necessary.

The author added much to my understanding by providing a detailed account of all of the Specialty Tools and Procedures to follow...that included the information on the necessary and very expensive Kent-Moore Head Bolt Extraction Kit.... and the two other required items for evacuating the Engine Block Bolt Holes using the exact size BOTTOMING TAPS to properly prepare the thread innards to accept a new set of TTY Bolts... and kill Two Birds with One Stone: (A) Clean out the Residual Broken Bolt Metal Remnants ...and... (B) Smooth all of the threads so that the new TTY Bolts would neither Grab nor Gall the Aluminum Block and have the same cascade failure cycle repeat itself.

The salient information I needed to be reminded of was this:

(A) A Bottoming Tap of with the Metric Thread Dimensions of M11 X 2.00 would be an absolute necessity for the Post-Removal Clean Up of the Bare Engine Block Head Face, while an entirely DIFFERENT Bottoming Tap would be necessary to deal with any Broken TTY Bolts holding in the Crankshaft Bearing Caps and Cage... also notorious for snapping off in the same fashion....and...

(B) I needed to be reminded that I had already purchased a short Machine Shop version of this tool last year and somehow, during the period in between, I had completely forgotten about buying the damned thing! Well...today, this memory came flooding back with a vengeance as I was mulling things over while considering the problem from the Block Side where the threads are instead of thinking about that damned complicated Aluminum Engine Head. HERE is ARP's BEST TOOL for this necessary clean-out job:

Naturally... the whole original idea was to locate Four Bolts of an M11 X 2.00 X 200MM variety to act as Top Down Guide Pins to ensure a correct SPACEX- like ”Falcon 9 Rocket Booster Landing” with a FLAWLESS alignment to get the Aluminum Engine Head perfectly in place...and thereby...cut out all the busy work of having to laboriously tear down the entire Factory Valve Train Installed Components...just to set the GD thing on the Engine Block!

This search proved to be even MORE serendipitous though, when I discovered that ARP sells a VERY LONG Thread Cleaning Tap with the dimensions of M11 X 2.00 X 180MM... and Hell...when you look at the image of this tool...you might think... “Bobby..Why not just get FOUR of THESE … use THEM as your Guide Pins...and be done with it?” ...and I WOULD …except that doing so would cost me around $60 X 4 = $240.00 Plus S&H... so no... the mission now moves back towards trying to find a set of Four Bolts long enough to get this job done..without having to Break the Bank at Monte Carlo. I just ordered one of these ARP Long Thread Cleaners. And so the search for these Four Mystery Guide Bolts will continue...

“All Solutions... Breed New Problems...”

Felpro provides their take on the burgeoning TTY Fasteners Market they will also be selling in:

http://www.felpro-only.com/blog/proper-installation-use-t-t-y-bolts/

Felpro Mechanic Testing TTY Bolts...

Felpro Mechanic Demonstrating "Which Side Is UP? How to Recognize Felpro Gasket Markings"

In this case... the answer to the question mentioned above came to me all of a sudden when I realized that at some point in the last five months...I had read an interesting Technical Article concerning the GM introduction and regular use of TTY Bolts as their Standard Fasteners, specifically addressing the problems being encountered with Head Bolts easily snapping off during repairs at both ends of the work when dis-assembly and/or re-assembly of the GM Atlas 4.2l Engine became necessary.

The author added much to my understanding by providing a detailed account of all of the Specialty Tools and Procedures to follow...that included the information on the necessary and very expensive Kent-Moore Head Bolt Extraction Kit.... and the two other required items for evacuating the Engine Block Bolt Holes using the exact size BOTTOMING TAPS to properly prepare the thread innards to accept a new set of TTY Bolts... and kill Two Birds with One Stone: (A) Clean out the Residual Broken Bolt Metal Remnants ...and... (B) Smooth all of the threads so that the new TTY Bolts would neither Grab nor Gall the Aluminum Block and have the same cascade failure cycle repeat itself.

The salient information I needed to be reminded of was this:

(A) A Bottoming Tap of with the Metric Thread Dimensions of M11 X 2.00 would be an absolute necessity for the Post-Removal Clean Up of the Bare Engine Block Head Face, while an entirely DIFFERENT Bottoming Tap would be necessary to deal with any Broken TTY Bolts holding in the Crankshaft Bearing Caps and Cage... also notorious for snapping off in the same fashion....and...

(B) I needed to be reminded that I had already purchased a short Machine Shop version of this tool last year and somehow, during the period in between, I had completely forgotten about buying the damned thing! Well...today, this memory came flooding back with a vengeance as I was mulling things over while considering the problem from the Block Side where the threads are instead of thinking about that damned complicated Aluminum Engine Head. HERE is ARP's BEST TOOL for this necessary clean-out job:

Naturally... the whole original idea was to locate Four Bolts of an M11 X 2.00 X 200MM variety to act as Top Down Guide Pins to ensure a correct SPACEX- like ”Falcon 9 Rocket Booster Landing” with a FLAWLESS alignment to get the Aluminum Engine Head perfectly in place...and thereby...cut out all the busy work of having to laboriously tear down the entire Factory Valve Train Installed Components...just to set the GD thing on the Engine Block!

This search proved to be even MORE serendipitous though, when I discovered that ARP sells a VERY LONG Thread Cleaning Tap with the dimensions of M11 X 2.00 X 180MM... and Hell...when you look at the image of this tool...you might think... “Bobby..Why not just get FOUR of THESE … use THEM as your Guide Pins...and be done with it?” ...and I WOULD …except that doing so would cost me around $60 X 4 = $240.00 Plus S&H... so no... the mission now moves back towards trying to find a set of Four Bolts long enough to get this job done..without having to Break the Bank at Monte Carlo. I just ordered one of these ARP Long Thread Cleaners. And so the search for these Four Mystery Guide Bolts will continue...

“All Solutions... Breed New Problems...”

Felpro provides their take on the burgeoning TTY Fasteners Market they will also be selling in:

http://www.felpro-only.com/blog/proper-installation-use-t-t-y-bolts/

Felpro Mechanic Testing TTY Bolts...

Felpro Mechanic Demonstrating "Which Side Is UP? How to Recognize Felpro Gasket Markings"