Its another rainy and blustery day here... and thus, the last kind of weather that anyone with any common sense would attempt working on an open topped engine parked out their driveway. Instead... I have used some of the time today to make an order for the requisite Cleaning Supplies needed to do this job right. I like to think about this critical phase of Pre-Assembly using:

"The Three to One Rule" ---- Simply stated, if you intend on using 100% of your Mechanical Skills and Attention to Details during the Disassembly of your Engine... then you must use 300% of that same Skill-Set during the Cleaning and Preparation Phase to ensure the cleanliness of the mating up areas of any and all surfaces that require Gaskets or Seals... and ALL BOLT HOLES CHASED AND SPRAYED OUT CLEAN. They must all be PERFECTLY CLEAN AND DRY before bolting these components onto the Engine Block.

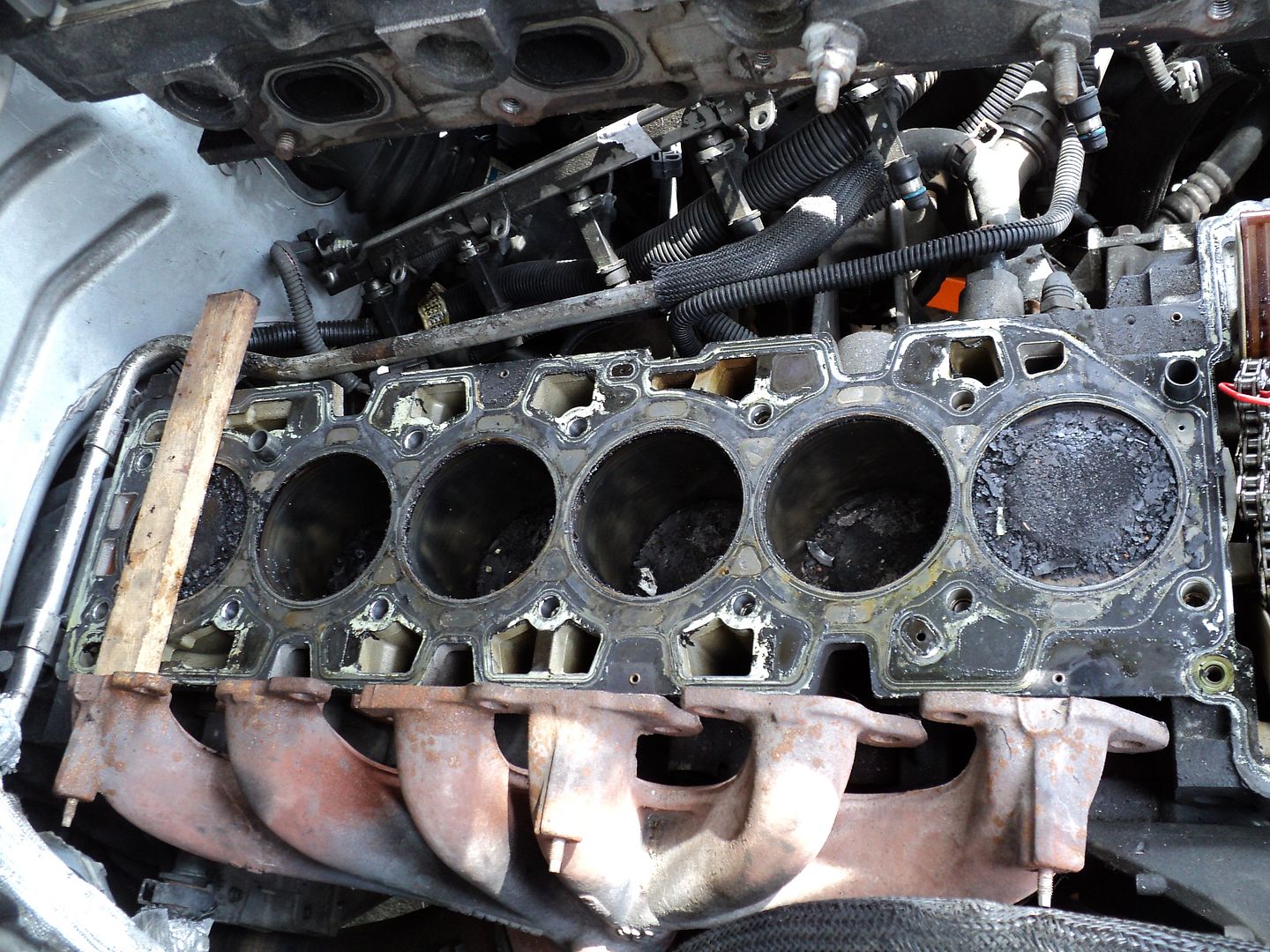

In this case... since I am installing a Brand New Engine Head... my obligation is to clean out the Combustion Chambers and Flat Surfaces of any and all Dirt, Oil, Preservative and Packing Residue with a Lint-Free Cloth...as well as running a Thread Chaser through the Spark Plug Holes. Once cleaned and sprayed down with a Solvent that leaves Absolutely NO RESIDUE... then the Components not being immediately installed should be thoroughly wrapped up in new Saran Wrap to prevent even the slightest contamination before being installed onto the Gasket(s) aligned on the Engine Block and bolted down via the Gospel and Verse of the OEM Torque Pattern and Recommended Torque Settings and finally... finishing off the job with the correct degrees of turn for the TTY settings required for each Fastener.

All of the fasteners that do NOT come with OEM Thread Sealants applied should first be Lightly Wire-Brushed on all the threads and subsequently be washed in Very Hot, Soapy Water and then Immediately Dried with either a Heat Gun... or by spraying down each one with a non-residue forming solvent. Do NOT apply any lubricants without consulting the specifications for fastener installation in the manual FIRST. In some cases... certain fasteners that pass through or dwell within the Water Column or Coolant Passages will require having the proper Water, Oil and Gas Resistant SEALANT applied to the Threads and Shanks to prevent the coolant from leaking out of the block and into places it should not be.

If you have your Fasteners stored inside one location and either the Engine on a Stand or the Engine in the Vehicle is located in another... it will be necessary to "normalize" them by having the Fasteners acclimated to the ambient temperatures where the Engine dwells. You do NOT want a huge temperature variance between them, as you run the risk of Damaging the Engine, Breaking the Fasteners or getting improper Fastener Torque if they are very far apart in how cold or hot these components happen to be when used. Having a temperate work environment when putting Major Engine Components together is conducive to a successful outcome.

Likewise... these fasteners should be placed inside Pre-Marked Plastic Zip-Lock Baggies in their respective sets, depending upon the orders for their installation. In some cases... certain fasteners are to be Oiled on the Threads and Under the Base of the Bolt Head and Hardened Steel Washers to ensure that the Fasteners Do NOT Grab, Stick or Gall under the compressive forces they are designed to ensure an accurate application of High Levels of Torque.

In the case of the GM Atlas 4.2L TTY Head Bolts... I will be defying the Factory OEM convention of installing these Fasteners BONE DRY... by applying an EXTREMELY LIGHT COATING OF 3&1 Oil that will then be very thoroughly wiped clean from the threads and leave only the slightest residue therein. The reason for this contingency is that the GM OEM Reps have made this recommendation due to the extremely high number of these Fasteners Snapping Off during standard installation procedures.

More on Procedures and Cleaning Products in the Next Installment...

"The Three to One Rule" ---- Simply stated, if you intend on using 100% of your Mechanical Skills and Attention to Details during the Disassembly of your Engine... then you must use 300% of that same Skill-Set during the Cleaning and Preparation Phase to ensure the cleanliness of the mating up areas of any and all surfaces that require Gaskets or Seals... and ALL BOLT HOLES CHASED AND SPRAYED OUT CLEAN. They must all be PERFECTLY CLEAN AND DRY before bolting these components onto the Engine Block.

In this case... since I am installing a Brand New Engine Head... my obligation is to clean out the Combustion Chambers and Flat Surfaces of any and all Dirt, Oil, Preservative and Packing Residue with a Lint-Free Cloth...as well as running a Thread Chaser through the Spark Plug Holes. Once cleaned and sprayed down with a Solvent that leaves Absolutely NO RESIDUE... then the Components not being immediately installed should be thoroughly wrapped up in new Saran Wrap to prevent even the slightest contamination before being installed onto the Gasket(s) aligned on the Engine Block and bolted down via the Gospel and Verse of the OEM Torque Pattern and Recommended Torque Settings and finally... finishing off the job with the correct degrees of turn for the TTY settings required for each Fastener.

All of the fasteners that do NOT come with OEM Thread Sealants applied should first be Lightly Wire-Brushed on all the threads and subsequently be washed in Very Hot, Soapy Water and then Immediately Dried with either a Heat Gun... or by spraying down each one with a non-residue forming solvent. Do NOT apply any lubricants without consulting the specifications for fastener installation in the manual FIRST. In some cases... certain fasteners that pass through or dwell within the Water Column or Coolant Passages will require having the proper Water, Oil and Gas Resistant SEALANT applied to the Threads and Shanks to prevent the coolant from leaking out of the block and into places it should not be.

If you have your Fasteners stored inside one location and either the Engine on a Stand or the Engine in the Vehicle is located in another... it will be necessary to "normalize" them by having the Fasteners acclimated to the ambient temperatures where the Engine dwells. You do NOT want a huge temperature variance between them, as you run the risk of Damaging the Engine, Breaking the Fasteners or getting improper Fastener Torque if they are very far apart in how cold or hot these components happen to be when used. Having a temperate work environment when putting Major Engine Components together is conducive to a successful outcome.

Likewise... these fasteners should be placed inside Pre-Marked Plastic Zip-Lock Baggies in their respective sets, depending upon the orders for their installation. In some cases... certain fasteners are to be Oiled on the Threads and Under the Base of the Bolt Head and Hardened Steel Washers to ensure that the Fasteners Do NOT Grab, Stick or Gall under the compressive forces they are designed to ensure an accurate application of High Levels of Torque.

In the case of the GM Atlas 4.2L TTY Head Bolts... I will be defying the Factory OEM convention of installing these Fasteners BONE DRY... by applying an EXTREMELY LIGHT COATING OF 3&1 Oil that will then be very thoroughly wiped clean from the threads and leave only the slightest residue therein. The reason for this contingency is that the GM OEM Reps have made this recommendation due to the extremely high number of these Fasteners Snapping Off during standard installation procedures.

More on Procedures and Cleaning Products in the Next Installment...