Yes…

A Failing Fuel Pump can also trigger a P0171 Code.

So you might consider examining the behavior of the Fuel Pump in a Non-Invasive manner using either a PICO-Scope Model #2204A (or LATER Model) or a Hantek Model# 1008C along with using a Hantek Model# CC-65 Low Amperage Clamp.

What Equipment is Necessary for this type of Testing?

(1) A Laptop Computer.

(2) An Inexpensive Oscilloscope that should come with its own unique Scope Analysis Software.

(3) A Low Amperage Clamp set to around 20 Amps.

(4) A Hantek 20:1 Voltage Attenuator.

(3) A Fuse-able Link Loop with a 15 Amp Fuse installed. It MUST have Small Blades on the wire ends to plug into the Fuel Pump Relay Fuse Location and NOT Damage the Fuse Block insert points.

What am I supposed to be LOOKING for during this Test?

Watch THIS Video and follow along with the VOP (Video Original Poster) as he explains the simple set up and use procedures...just use the Fuel Pump Fuse on the GMT360 instead of a Fuel Pump Relay insert point as the VOP describes. The Principles will be the same whenever using a Low Amperage Clamp:

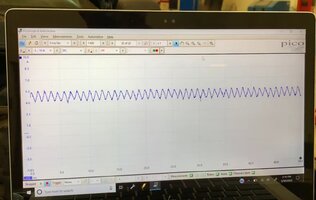

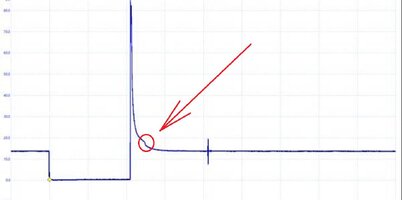

If your Fuel Pump is presently performing nominally, the “Voltage Over Time” Graph on your Laptop Screen should show a Good Wave Form as shown in this image:

View attachment 101969

That Jagged Horizontal Line is displaying the amount of the Amperage Draw on the Left Vertical Margin Scale and the Time Segment Scale on the Horizontal Axis. Those ‘Jagged Ups & Downs’ represent the individual Copper Commutator Segments inside of this Known Good Fuel Pump as they actuates under the influence of the 12 Volts DC running the Electric Pump and drawing in the necessary steady Amperage to function properly.

If YOU can see ANY Breaks or Gaps in that Jagged Horizontal Line that should appear as uniform as the example image, this would indicate a Damaged or Failing Fuel Pump and replacing the pump would be in order. Please understand that as long as your Oscilloscope Leads and Fuel Pump Fused Link Loop are good… then THIS Test is DEFINITIVE and will not involve any Guess Work.

Anyone can prepare for using this Equipment and Procedures by visiting the PICO-Scope Site and Downloading and Installing their FREE Software for your particular Laptop Computer Operating System. This nice feature here is that you can actually Practice Using the PICO Software ...without having to purchase any equipment first and determine if these types of procedures will help you, without having to just R&R the Fuel Pump without knowing whether it is actually having any subtle ...or major issues.

https://www.picotech.com/downloads

Amazon carries a wide range of Automotive Oscilloscopes and Suppot Equipment required to use them that range from just a few Hundred to Thousands of Dollars. THESE are the better Introductory Choices:

Hantek Model #1008C Kit (Eight Channels + Signal Generator):

Hantek 1008C 8CH Automotive Diagnostic Oscilloscope: Amazon.com: Industrial & Scientific

www.amazon.com

PICO-Scope Various Model Oscilloscopes (Two Channels:

Hantek Model #CC65 Low Amp Clamp:

Hantek 20:01 Voltage Attenuator: (NOT needed with the Low Amperage Clamp for THIS Test)

)

)