Hi,

I've posted about my issue with the P0171 awhile ago and I'm still chasing it and go no progress I'm no mechanic and I really need to fix this since on mechanic in my country was able to fix it (I'm not from the USA) so here's what I did so far:

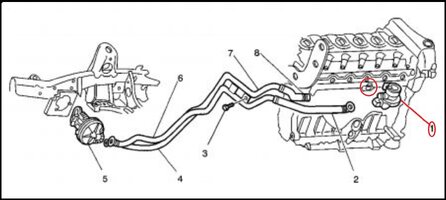

-Checked for vacuum leaks with a smoke machine and got none.

-Changed the intake manifold gaskets with Fel-Pro and torqued it to 89 inch pounds

-Cleaned fuel injectors and replaced the o-rings

-Replaced O2 upstream sensor with (ACDelco 213-1698)

-Replaced Fuel pressure regulator with (Standard Motor Products PR233)

-Replaced Fuel Filter (ACDelco GF831)

-Replaced Engine Coolant Temperature Sensor (ACDelco 213-963)

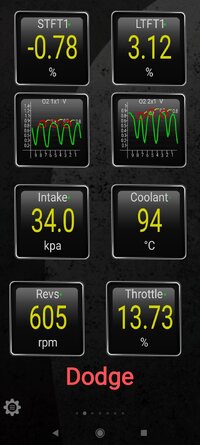

My idle jumped to ~900 rpm after the CEL on but whenever I clear the CEL is goes back to normal also my fuel pressure reading is at 48-49 psi with key on and truck off and about the same when the truck is on... I read online that the fuel pressure specs should be between 50-57 psi I'm using a cheap fuel pressure gauge and I believe my fuel pressure readings are a bit low however it doesn't effect my truck's startup or overall performance I need your input on my fuel pressure readings.

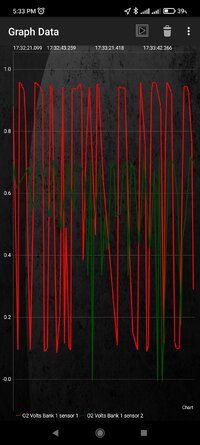

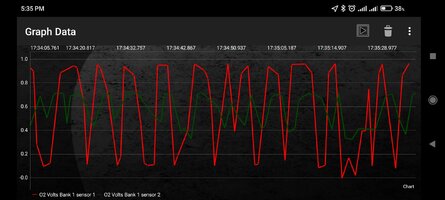

Regarding my fuel trims, I'm using a cheap OBDII scanner and Torque app to monitor my fuel trims after changing the intake manifold gaskets my CEL was cleared both of my STFT and LTFT readings are within +3.5 and -3.5 % even after triggering the P0171 code my STFT and LTFT didn't increase which I guess is strange correct me if I'm wrong but shouldn't my STFT and LTFT be higher than +15% to trigger the code?

I'm very frustrated as my truck ran normally after changing the intake manifold gaskets for about 100mi and I thought my issue was fixed, I'm in a desperate need for the guidance of the veterans of this forum, any help is greatly appreciated.

Thank you in advance.

I've posted about my issue with the P0171 awhile ago and I'm still chasing it and go no progress I'm no mechanic and I really need to fix this since on mechanic in my country was able to fix it (I'm not from the USA) so here's what I did so far:

-Checked for vacuum leaks with a smoke machine and got none.

-Changed the intake manifold gaskets with Fel-Pro and torqued it to 89 inch pounds

-Cleaned fuel injectors and replaced the o-rings

-Replaced O2 upstream sensor with (ACDelco 213-1698)

-Replaced Fuel pressure regulator with (Standard Motor Products PR233)

-Replaced Fuel Filter (ACDelco GF831)

-Replaced Engine Coolant Temperature Sensor (ACDelco 213-963)

My idle jumped to ~900 rpm after the CEL on but whenever I clear the CEL is goes back to normal also my fuel pressure reading is at 48-49 psi with key on and truck off and about the same when the truck is on... I read online that the fuel pressure specs should be between 50-57 psi I'm using a cheap fuel pressure gauge and I believe my fuel pressure readings are a bit low however it doesn't effect my truck's startup or overall performance I need your input on my fuel pressure readings.

Regarding my fuel trims, I'm using a cheap OBDII scanner and Torque app to monitor my fuel trims after changing the intake manifold gaskets my CEL was cleared both of my STFT and LTFT readings are within +3.5 and -3.5 % even after triggering the P0171 code my STFT and LTFT didn't increase which I guess is strange correct me if I'm wrong but shouldn't my STFT and LTFT be higher than +15% to trigger the code?

I'm very frustrated as my truck ran normally after changing the intake manifold gaskets for about 100mi and I thought my issue was fixed, I'm in a desperate need for the guidance of the veterans of this forum, any help is greatly appreciated.

Thank you in advance.