ChevyTBLover

Member

- Joined

- Nov 21, 2011

- Posts

- 116

, ideas are flowin lol... I think the wood needs to go on top and below it though... the painted fiberglass is standing out too much but if the whole cluster panel matched, I think it would look tits... clean install bro...

, ideas are flowin lol... I think the wood needs to go on top and below it though... the painted fiberglass is standing out too much but if the whole cluster panel matched, I think it would look tits... clean install bro...

Boricua SS said:everybody is jumpin on the tablet wagon... hmmmm.., ideas are flowin lol... I think the wood needs to go on top and below it though... the painted fiberglass is standing out too much but if the whole cluster panel matched, I think it would look tits... clean install bro...

yodaddy4200 said:Well here they are... They work perfect!! It was kinda sunny when i took the pick but they should be bright enough during the day i think

View attachment 15599

View attachment 15600

wesman43 said:Is it more practical to buy the LED flasher than it is to use resistors?

wesman43 said:Is it more practical to buy the LED flasher than it is to use resistors?

ChevyTBLover said:

ChevyTBLover said:

You've given me the fevah (Maine accent)!

You've given me the fevah (Maine accent)!

JCJARHEAD said:I have been perusing this thread through the years....wishing I could do more LEDs. I have the cabin lights done...that was relatively easy as those bulbs were plug and play. I also did the CHMSL with using the "Avalanche protocol." Works great!

I have since lost about 3 cluster lights....and I can't stand it! SO....Although I have NEVER soldered a thing in my life....I am going to attempt to do my cluster bulbs with some LEDs I got off of ebay. Thanks to Roadie I had purchased and learned to use a multi-meter a while back. If I can't figure LED polarity visually....I think I can set it to diode, attach leads, and see if bulb lights up.

I will report back once complete. I have some time this coming weekend so I hope to get underway with it. I have watched some "how to solder" and "gauge cluster" vids on Youtube to help my confidence and pick up any tips.

I looked into some of the services, and some seemed alright....but after seeing the process. I decided to try myself....I have purchased a solder iron, solder sucker, all LEDs (went with BLUE)..also bought the BLUE needles. I will also do the stepper motors eventhough mine are fine at 135l miles....since I am already in there? Got the latest model motors.

Dont even get me started on the HVAC controls...at least not yet!

Thanks to all who've posted in this thread...and mostly to Blckshdw for his relentless advocacy of LEDs!You've given me the fevah (Maine accent)!

JCJARHEAD said:GM Instrument Cluster Bulb Replacement Kit Gauge Speedometer Lamp Repair | eBay

If anyone has any feedback re these devices (the right power?).....or any other part of the process.....I always welcome the insightful advice of the knowledgeable GMT Nation!

DDonnie said:This is just my suggesstion, but i think it's especially true for a beginner. I was frustrated for years and convinced i couldnt solder because i was using a cheap soldering iron. As soon as i bought a temp controlled iron, i realized i wasnt the one the couldnt solder, it was my soldering iron. I would strongly suggest purchasing a nicer iron as soon as you get a chance. They are pricier, but they are worth it. Also, a little bit of solder wick might work better for you than the solder sucker, but thats just my preference.

JCJARHEAD said:Thanks for the advice! I will look into both. Can you suggest an appropriately calibrated iron for use on the gauge cluster? Or features to have in addition to temp control. To your point....we're breaking my solder cherry here so let's do it right!

)....that I am getting a bit more brazen in my DIY attempts. And of course my GMT Nation safety blanket gives me confidence as well.

)....that I am getting a bit more brazen in my DIY attempts. And of course my GMT Nation safety blanket gives me confidence as well.

DDonnie said:Digital Soldering Station : Soldering tools & supplies | RadioShack.com

This is the one i have, i got it for 50 or 60 on sale. Basically, i would look for one that has a temp controller, changable tips, and a station to rest the iron as well as a tip cleaner.

You can get ones for much cheaper, but this seemed like a good iron for the price and i was in a hurry.

JCJARHEAD said:One more important question? What temperature do you recommend for use on our cluster's circuit board? Read a lot about not getting carried away with heat and lifting the pad and such? Hoping to avoid that.

Was hoping since the one I bought on eBay was marketed as GMC cluster repair, that it would be pre set or just the right power.

Blckshdw said:This is the iron I upgraded to, after (like DDonnie) I realized my Radio Shack starter iron was a POS. Also got some different shaped tips, which are very useful.

[EBAY]270901702389[/EBAY] [EBAY]270771000535[/EBAY]

Blckshdw said:This is the iron I upgraded to, after (like DDonnie) I realized my Radio Shack starter iron was a POS. Also got some different shaped tips, which are very useful.

[EBAY]270901702389[/EBAY] [EBAY]270771000535[/EBAY]

Do you have any more advice you would like to impart?

Do you have any more advice you would like to impart?Sparky said:A while ago I treated myself to this station:

Weller WESD51 Digital Soldering Station - Amazon.com

Night and day difference when soldering with it vs my old $5 wally world special!

A bit pricey but I don't think I'll ever really need to upgrade.

I've soldered at a bunch of different temperatures depending on what I'm working with (never needed 850 degrees however!). Lead-free solder takes more heat to melt. I don't solder with lead-free however, the lead-based stuff is easier to work with and a lot more forgiving. Lead free can be brittle when cool, a lot of electronics failures from a few years ago when they first really started pushing it can be traced to bad solder joints.

JCJARHEAD said:...Do you have any more advice you would like to impart?

Blckshdw said:Getting back on topic...

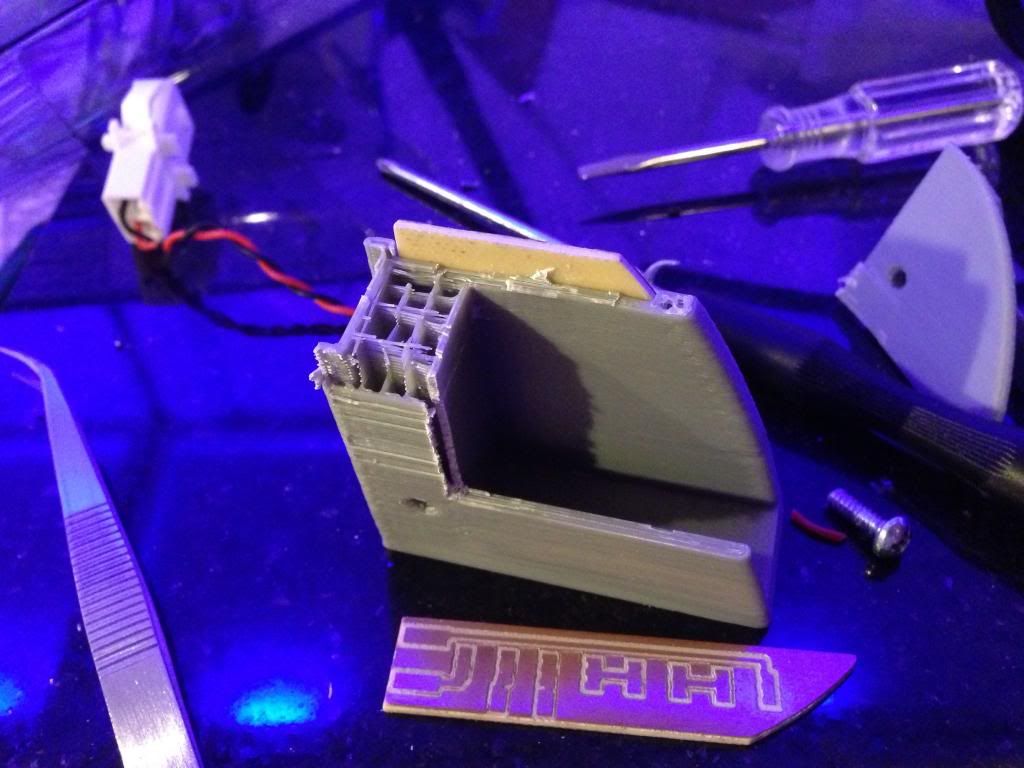

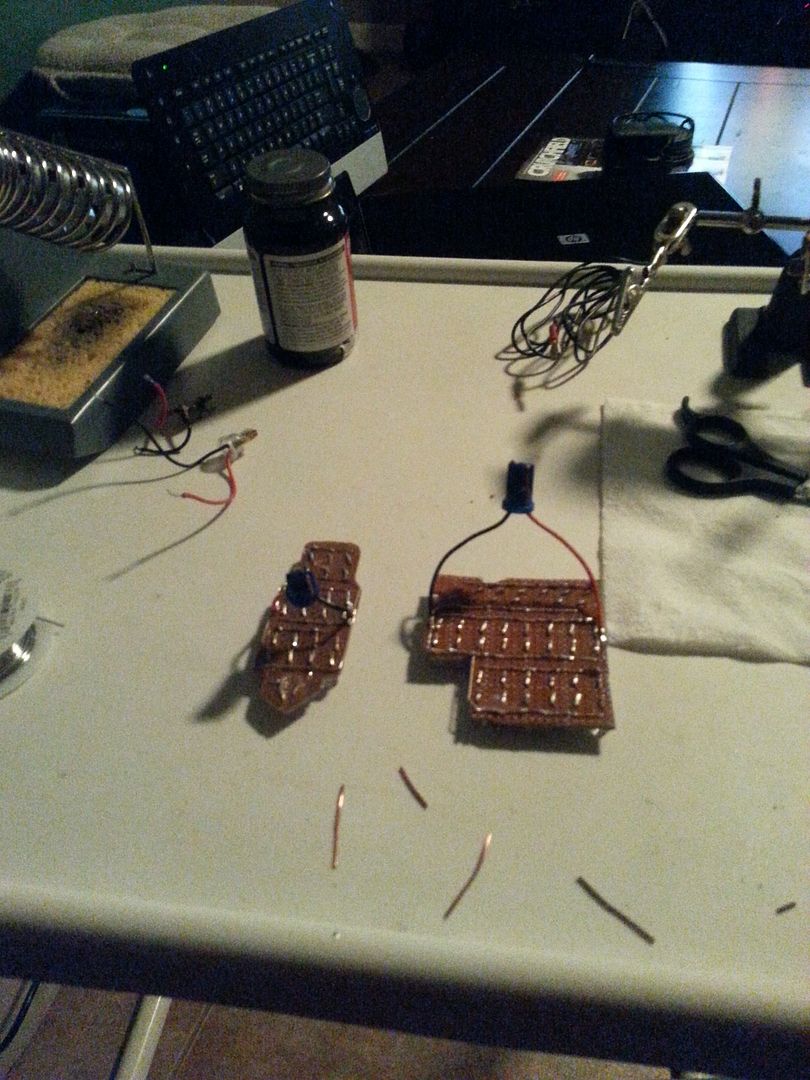

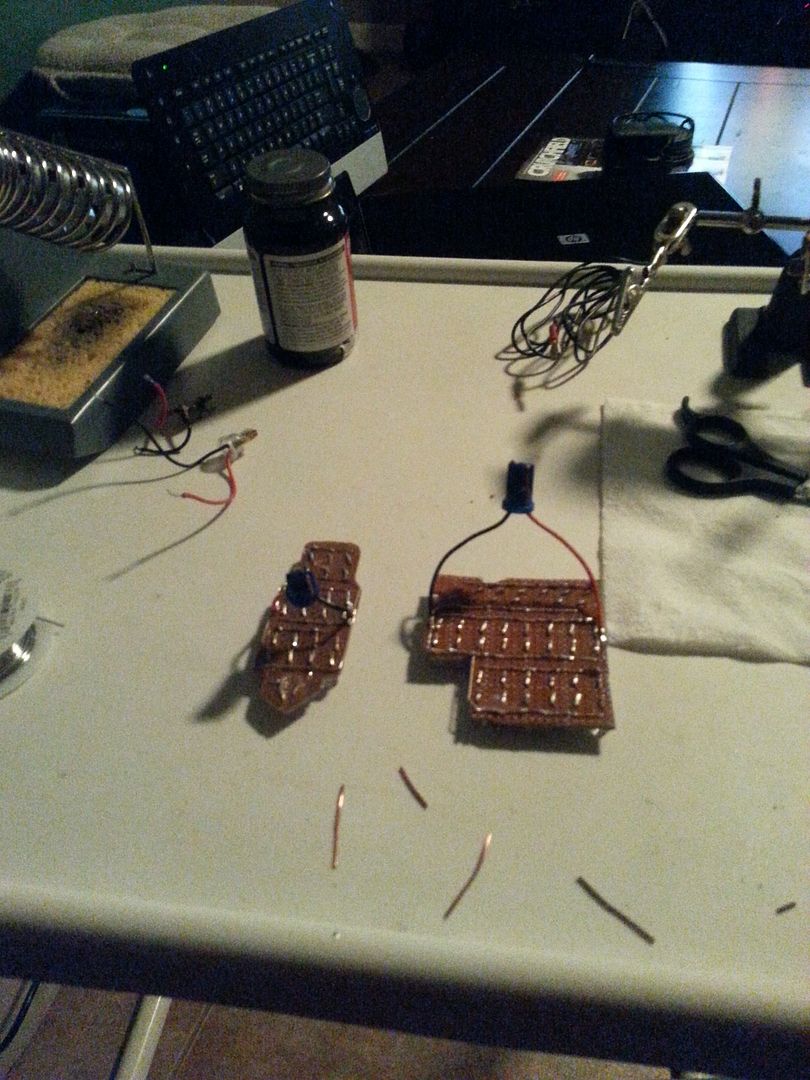

Fresh set of empty 194 bases showed up from China today, so time to fix my burnt up dome lights. One for the front row, one for the third row.

Quick test with the power supply, much mo betta!

Now to silicone the front row ones back in the overhead console, and let that set overnight so I can reinstall them tomorrow after work.

DDonnie said:Question, what do you use for your bench power supply? Right now, i have a rigged cigarette lighter power supply with a modified adapter.

Boricua SS said:I sanded the tops of my bulbs and it virtually eliminated all hotspots on my HVAC controls...

See the 2 hotspots on my rear wiper controls? I didn't sand those bulbs.. now look at my HVAC.. nothing but smooth output..

kjkim93 said:Even though I bought flat top LEDs? I'm going to do the cluster and headlight switch and wiper switch. Should I get a very high grit sand paper then?

DDonnie said:dude, your vents turned out so much better than mine. I'm thinking about redoing them.

kjkim93 said:Does anybody know where I can get instructions to change the steering wheel controls?

kjkim93 said:So my leds and resistors have finally come in today. and tips or warnings before I do this next week? ive gathering all the information off this site which im thankful for.

and this may sound trivial...but check your led's BEFORE soldering them in...nothing worse that taking your time and making everything look perfect, only to find out one of your bulbs is fubar

and this may sound trivial...but check your led's BEFORE soldering them in...nothing worse that taking your time and making everything look perfect, only to find out one of your bulbs is fubar