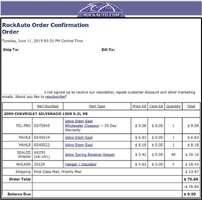

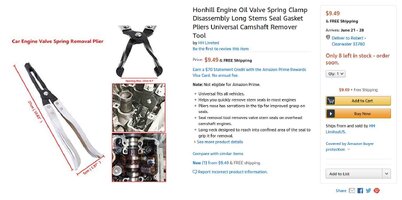

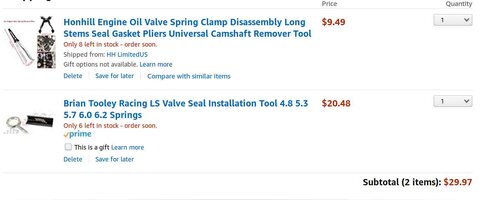

It is a rare occasion when I can find a "Suitable Cheap Replacement' for my demand to use the Best Tools and Materials I can find for Engine Building. But in THIS case... Spending $80.00 for what amounts to being just being (2) 5/16" X 36" Mild Steel Rods to slide in through the two Hollow Ports under either side of the Camshaft Cover Retention Plate and keep the Disaster of Dropping (1) or MORE Roller-Lifters Down inside the LM-7 Engine Block from happening is STILL WAY more Money than I'd care to pay.

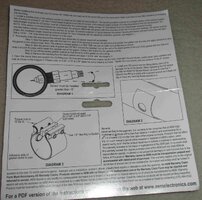

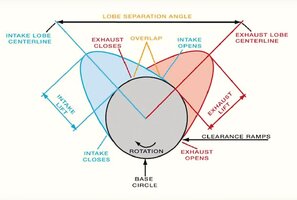

Using this Pair of Rods is a 'Necessary Evil' to ensure that ALL 16 Roller-Lifters will Remain Held UP Inside of the Lifter Trays after giving a few Quick Spins on the Nose of the Camshaft using a few Water Pump Bolts threaded in the nose of the camshaft to get enough Action on The Spin. The idea is that the Quick Rotational Velocity is supposed to Stuff all of the Roller Lifters high and tight up inside of their Black Plastic Retention Trays.

Ordinarily, that action alone on Newer or even Low Mileage Engines like my LM7 (73,000 Miles after 19 Years) would be enough to ensure that they all would remain held fast while performing the Camshaft R&R. But should any Mechanic suffer from the Fates and Gravity in that Moment... and if any of those Roller Lifters were to drop down into the bowels of the Engine... It would require a Total Re-Build of the Motor to get out the THAT Hell after experiencing such an unfortunate eventuality.

Still... In spite of my reticence to Drop $80.00 for this "Specialty Camshaft Roller Rocker Retention Tool Kit"... I think I've found a Respectable Substitute with the purchase of a (3) Pack of 5/16" X 36" Set of SMOOTH ALUMINUM RODS for only $19.18 with FREE S&H off of eBay. The only additional precautions I need to take is to Round and Smooth Over the two "Business Ends" of these Two Aluminum Rods. I've already seen too many YouTube Videos on LS Camshaft Swaps where the intrepid Mechanics wind up using 5/16" Wooden Dowels that can be observed snapping off here and there and leaving all sorts of debris inside of their engines... So I can only guess that my choice of using the more favorable and forgiving Rods made out of Aluminum will prove to be the Better Alternative.

But just in case there is any Metal to Metal resistance... I'll have them both lubed up with plenty of Perma-Tex "Ultra-Slick" Purple Jesus Engine Assembly Lube to ensure they can easily slide into each side of those two Hollow Ports under the Camshaft Cover ...directly underneath every single Roller Lifter and also reach all the way to the Back of the Engine Block.

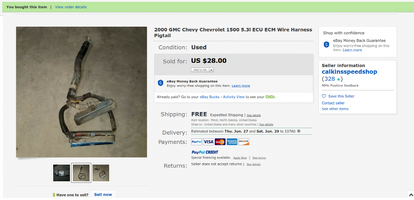

Getting this task right means preventing any sudden drops of these (16) Slippery, Heavy Little Metal Cylinders... before I'm able to get the Old Camshaft OUT ... and the New TSP 212/218 112 LSA 550"/550" Camshaft correctly INstalled... as nicely as you please ...and then carefully withdraw those Aluminum Rods. I did a brief calculation of how many of these Tools Sets one eBay Vendor had sold... (27) Pairs X $80.00 ...just to figure out what the Profit Margin was on (54) 5/16" X 36" Mild Steel Rods. This came to be a figure of $2,160.00 ... So No WONDER the "S&H" on those (27) Sales were FREE!

I'm not certain how much these Aluminum Rods can be Bent to sort of Guide them inside of the Engine on a 'curve'. So the proximity of the Front of the Engine Block to the Radiator and Condenser Coil may become a critical factor to consider. However, since I have the Third Aluminum Rod to Experiment with... I'll look things over ahead of time and use IT to see whether on not it becomes absolutely necessary to Remove the Radiator Core AND move or adjust the Condenser upwards to clear the straighter path if needed to get both Rods inserted properly and NOT get them jammed up inside of the Motor. See the Attached Images for comparisons among these "Metal Rods":

Using this Pair of Rods is a 'Necessary Evil' to ensure that ALL 16 Roller-Lifters will Remain Held UP Inside of the Lifter Trays after giving a few Quick Spins on the Nose of the Camshaft using a few Water Pump Bolts threaded in the nose of the camshaft to get enough Action on The Spin. The idea is that the Quick Rotational Velocity is supposed to Stuff all of the Roller Lifters high and tight up inside of their Black Plastic Retention Trays.

Ordinarily, that action alone on Newer or even Low Mileage Engines like my LM7 (73,000 Miles after 19 Years) would be enough to ensure that they all would remain held fast while performing the Camshaft R&R. But should any Mechanic suffer from the Fates and Gravity in that Moment... and if any of those Roller Lifters were to drop down into the bowels of the Engine... It would require a Total Re-Build of the Motor to get out the THAT Hell after experiencing such an unfortunate eventuality.

Still... In spite of my reticence to Drop $80.00 for this "Specialty Camshaft Roller Rocker Retention Tool Kit"... I think I've found a Respectable Substitute with the purchase of a (3) Pack of 5/16" X 36" Set of SMOOTH ALUMINUM RODS for only $19.18 with FREE S&H off of eBay. The only additional precautions I need to take is to Round and Smooth Over the two "Business Ends" of these Two Aluminum Rods. I've already seen too many YouTube Videos on LS Camshaft Swaps where the intrepid Mechanics wind up using 5/16" Wooden Dowels that can be observed snapping off here and there and leaving all sorts of debris inside of their engines... So I can only guess that my choice of using the more favorable and forgiving Rods made out of Aluminum will prove to be the Better Alternative.

But just in case there is any Metal to Metal resistance... I'll have them both lubed up with plenty of Perma-Tex "Ultra-Slick" Purple Jesus Engine Assembly Lube to ensure they can easily slide into each side of those two Hollow Ports under the Camshaft Cover ...directly underneath every single Roller Lifter and also reach all the way to the Back of the Engine Block.

Getting this task right means preventing any sudden drops of these (16) Slippery, Heavy Little Metal Cylinders... before I'm able to get the Old Camshaft OUT ... and the New TSP 212/218 112 LSA 550"/550" Camshaft correctly INstalled... as nicely as you please ...and then carefully withdraw those Aluminum Rods. I did a brief calculation of how many of these Tools Sets one eBay Vendor had sold... (27) Pairs X $80.00 ...just to figure out what the Profit Margin was on (54) 5/16" X 36" Mild Steel Rods. This came to be a figure of $2,160.00 ... So No WONDER the "S&H" on those (27) Sales were FREE!

I'm not certain how much these Aluminum Rods can be Bent to sort of Guide them inside of the Engine on a 'curve'. So the proximity of the Front of the Engine Block to the Radiator and Condenser Coil may become a critical factor to consider. However, since I have the Third Aluminum Rod to Experiment with... I'll look things over ahead of time and use IT to see whether on not it becomes absolutely necessary to Remove the Radiator Core AND move or adjust the Condenser upwards to clear the straighter path if needed to get both Rods inserted properly and NOT get them jammed up inside of the Motor. See the Attached Images for comparisons among these "Metal Rods":

But I do love my new (to me) Sierra, even if there's MORE total work / investment to make on it, than the old one.

But I do love my new (to me) Sierra, even if there's MORE total work / investment to make on it, than the old one.