As a timely nod of

"Congratulations!" to

@gmcman on his recent acquisition of an

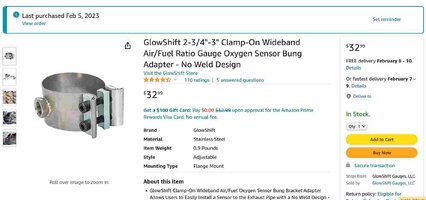

AES Wideband O2 Sensor Kit... Here is some more "On Topic" information about the many considerations involved with

Installing New O2 Sensor Bungs if doing so becomes necessary that FIT the requirements necessary for the more sensitive

AEM Bosch Wide Band O2 Sensor. These are "The Top Ten":

(1) Placement and Angle of the O2 Sensor Bung is critical... especially with a Turbo-Charger installed. Placing them Too Close and/or Facing in the Wrong Direction or Angle will expose the Bosch Sensor to

WAY TOO MUCH UNBURNED FUEL and cut short its Life Expectancy.

(2) TIG or Gas Welding in the Sensor Bung must take into consideration the thickness of the Pipe or adjacent manifold and focus most of the Electrode "Puddle" on the Thick Bung Adapter itself... and NOT on the Thin Walled Header Pipe

WHICH WILL BURN THRU IN AN INSTANT.

(3) Due to the Spatter and 'noisy excitement' of "Red HOT Buck Shot & BBs" dropping down on top of you ...one should refrain from using a MIG or Flux-Core Welder while laying underneath the Vehicle. Flux-Core Welding should only be used if necessary when Welding on a Flat-Horizontal Plane. If the Sensor Bung can be fitted to a sub-component prior to the Complete Headers-Piping Installation while working on the Welder's Table...

so much the better.

(4) It will be difficult in some case to run multiple beads in order to close up any 'Burn-Thrus" while laying on your back. Also, in most cases you should only make Single Passes when using Flux-Core Wire. 'Tack Welding' in One or Two 2 second bursts...

sort of 'Connecting The Dots' will Kill Two Problems ...with

"One String of Beads".

(5) Even on

Fully Stainless Steel Exhaust Systems... the Sensor Bung placement should be made anywhere between the 3 O'clock to 9 O"clock Positions with the optimum positions being in between the 2 O'clock and 10 O'clock Positions. This will prevent the

Water as a

HUGE By-Product of

Combustion from settling or collecting deep inside of the

Sensitive Bosch O2 Sensor Zirconium Silica portion ...and damaging it.

(6) If the placement of the Sensor Bung is limited by crowded spacing... adjust the position of the Add-In Bung to be slightly forward and off angle form the Original and install the

AES Bosch O2 Sensor in the Factory Bung location.

(7) Never Install a Wide Band O2 Sensor Bung

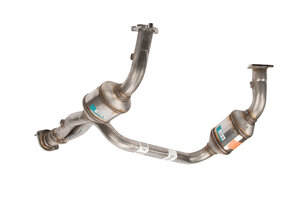

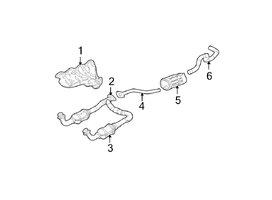

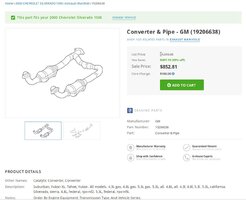

AFTER the Catalytic Converter in the Outflow Pipe, as providing a TRUE Air to Fuel Ratio measurement AFTER "Letting The Horses Out of The Barn" will NOT work.

(8) Make certain to pick the right Shape and Angle of the Sensor-to-Piping interface using the correct shaping, curvature or arc to exactly match the shape of the Exhaust Piping. The

Bosch Style O2 Sensor Design is longer than the Stock O2 Sensor with a

Thread and Pitch Count of M18 X 1.50.The greater depth is an effort to exclude any chance for Atmospheric Oxygen getting ingested and contaminating the Exhaust Stream.

(9) Mind the choices you make for the Welder Equipment and Electrode Rods or Wire Gauge. Using a

Sketchy Welding Technique may create Incomplete or Porous Weld Lines that will defeat the

Bosch O2 Sensor via Very Small Leaks. Even a Pin-Holes Size Defect will confuse the outcomes after you spend all of your Time,Effort and Expense investing in

HP-Tuners to get the VE Tables, MAF-IAT selections, Fuel Enrichment and a myriad of other problems that can be caused by a malfunctioning or mis-reading

Bosch O2 Sensor.

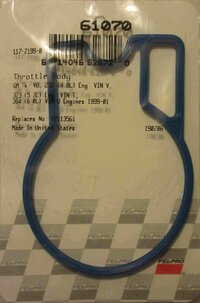

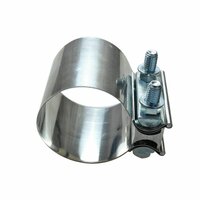

(10) In some cases... it will be necessary to Close Off certain Extra O2 Sensor Bungs that will NOT be needed and yet, they will still require the same Attention to Detail for containing the Noxious Exhaust Fumes and deadly Carbon Monoxide (CO).

Choosing

Non-Rusting, Stainless Steel O2 Bung Plugs with Copper Washers will make it easier in the long run to extract them later on if necessary and not have them all dissolve under Rusty Onslaught caused by exposure to Snow-Mud-Slushy Road Salt conditions.

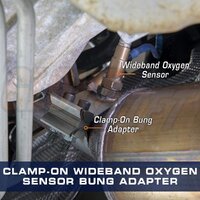

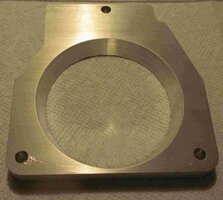

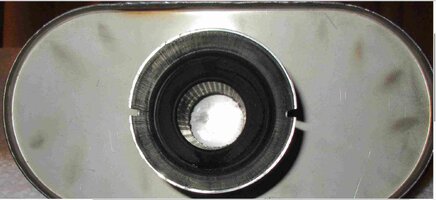

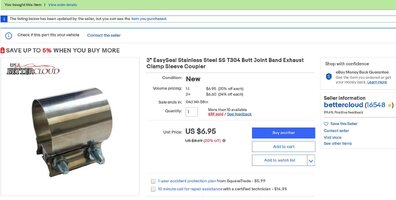

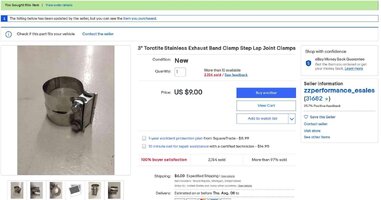

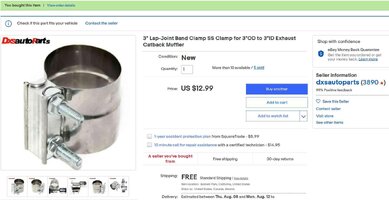

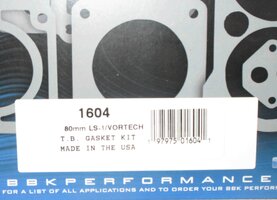

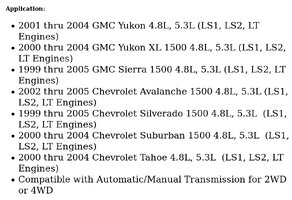

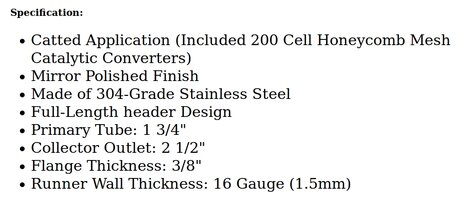

Here are some images of

High Quality S/S O2 Sensor Bungs and a Plug/Washer Combo:

gmtnation.com

gmtnation.com

)

)