Part Two of Two:

Don’t be disappointed if the bolt refused to budge even a little. Next, slip the 3’ Galvanized Pipe over the back end of the Breaker Bar by at least One Foot in depth and while ensuring that the 22 MM Deep Socket is still in place and at a Right Angle to the Breaker Bar…. Observe that the next actions do not accidentally tip over the Engine and Engine Stand. Now… apply Steady Downward Pressure by literally leaning your upper body weight at the outer areas of the “Extra Lever” and while applying Steady, Even Down Force… after a minute or so…. The Big Bolt will yield and come loose. After that is confirmed… you can switch to using a 1/2” Drive Ratchet to completely remove the Crankshaft Bolt.

But be Warned… Be prepared for a Horrendous Smell to escape from the hollow interior of the Crankshaft as the Bolt comes out. This is because whatever Organic Materials were used at the OEM Factory Assembly will have long since Decayed and left a Residue inside that is Pungent and Disgusting… so avoid breathing this stuff as much as you can as it will cause the onset of a severe headache… from whatever that awful, ancient material happened to be.

Next, unbolt the Crankcase Oil Pick-Up Tube at the the Tube Insertion Hole in the bottom of the Oil Pump and at the Metal Support and Hold Down Bracket and carefully extract the Tube. Note that there are Bolt Retainers that will keep the two 10 MM Fasteners in place with the Tube and set these items aside.

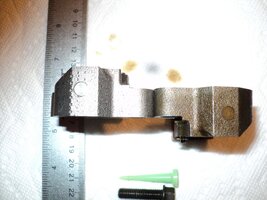

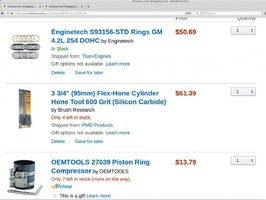

To Remove the Harmonic Balancer... THE ONLY TOOL THAT WILL WORK is the OTC Model #6667 (6) Piece Kit consisting of the Three Prong Tool with a Female threaded center and three, free-moving pinned arms that will allow you to adjust them into the groove positions shaped into the arms of the Harmonic Balancer. Next it the Hollow Center Pin with Fine Threads that require the application of High Pressure Grease to ease the stress of the thread-lines that will have to pull outwards with around 700 Fit Lbs of Torque in very tiny turning increments. To that is added a set of Heat Treated Steel Pins of varied lengths to allow this Kit a wider variety of applications.

Using the intermediate sized pin that gets stuck down inside the threaded bolt...the Puller Tool is guided with the pin entering to quite a depth inside of the Hollow Crankshaft and allowing the rounded end to seat in the Hollow Dead Center of the Crankshaft...and then the Three Arms must be held in position while inserting the Square end of a 3/8” Ratchet with an adjustable handle into the Square Hollow end of the Bolt… and by tightening slowly until all Three Arms have a good grip on the underside portions of the Harmonic Balancer… as the Tool Snugs up… place your free hand underneath the Harmonic Balancer and gradually tighten down the Black Center Bolt and you will feel the action working as the Puller slide the HB towards you. This will take a few minutes and finally...the Harmonic Balancer will drop off the end of the Crankshaft … right into the palm of your hand… Just… Like … That. Now… set the HB and OTC Tool aside for later inspection and clean-up… (Later on… I’ll be installing a Brand New Harmonic Balancer).

Son now on to removing the Timing Chain Cover … Use the 10MM X 3/8” Drive Socket and Ratchet and slowly loosen all of the Perimeter Fasteners and Bag them as you go along… But keep Two Bolts out to thread into Threaded Bolt Holes located towards the Bottom Outer Flange hollow rectangular pockets and after remove the last Smaller 8MM Fastener roughly centered in the near the middle of the Timing Chain Cover. Then gradually tighten the Two Bolts down until the GM Gray OEM RTV seal adhesion is broken and while being careful not to drop the Front Cover… gently pry it loose by holding the outer edges (these are very sharp and can cut you) and gently lift the cover off of the front of the Engine.

Well … I think that is enough activity for one day … I’m am done in right now and I’m going to try using some Tiger Balm Red on my lower left ankle and the arch of my foot to see if it works to bring down the damned swelling. The videos that follow on from here are the Best onces I have seen on this part of the repair and should be downloaded and saved for repeat viewing for the great information and GM OEM Part Numbers they provide for this job.

This Video shows the OTC Special Harmonic Balancer Puller Tool in Demonstration Action:

And Big Props go out here to Carlos Diaz for his Epic Set of Videos on the Bravada Repair to R&R the Entire Front Components of the GM 4.2L Engine and Replace the Fan Clutch, the Water Pump AND Most Importantly… the Harmonic Balancer, too:

Part 1

Part 2

Part 3

Part 4

Part 5

Not Available on Youtube….

This last video shows a Disaster in The Making from a different VOP if the Crankshaft Bolt should ever come LOOSE:

https://www.youtube.com/watch?v=nH1yRLZJw5Y

I’m pretty banged upright now… so I might need a few days to “Aggregate My Fecal Material” before moving on with the disassembly of the Timing Chain Set, The Timing Chain Guides, The Timing Chain Tensioner and the VVT Cam Phaser Sprocket, Timing Chain and Intake Sprocket. I will also have to do a dedicated post later that covers Cleaning up all of the Internal Engine areas using GM TEC as well. The R&R of the Engine Head will the “Last But Not Least” of these tasks before re-assembling everything with as many new components, gaskets and sealers as possible to get this engine “Ready for the Road...” Its surprising how clean this motor is inside...I really wish I had an accurate mileage on the Motor to show what one looks like when it “Ages Well”...All In All...THIS Really was a Pretty Damned Good Day!

Much More to Follow…

http://s557.photobucket.com/user/60...NEREPAIR/HARMONICBALANCEREMOVAL?sort=3&page=1

Don’t be disappointed if the bolt refused to budge even a little. Next, slip the 3’ Galvanized Pipe over the back end of the Breaker Bar by at least One Foot in depth and while ensuring that the 22 MM Deep Socket is still in place and at a Right Angle to the Breaker Bar…. Observe that the next actions do not accidentally tip over the Engine and Engine Stand. Now… apply Steady Downward Pressure by literally leaning your upper body weight at the outer areas of the “Extra Lever” and while applying Steady, Even Down Force… after a minute or so…. The Big Bolt will yield and come loose. After that is confirmed… you can switch to using a 1/2” Drive Ratchet to completely remove the Crankshaft Bolt.

But be Warned… Be prepared for a Horrendous Smell to escape from the hollow interior of the Crankshaft as the Bolt comes out. This is because whatever Organic Materials were used at the OEM Factory Assembly will have long since Decayed and left a Residue inside that is Pungent and Disgusting… so avoid breathing this stuff as much as you can as it will cause the onset of a severe headache… from whatever that awful, ancient material happened to be.

Next, unbolt the Crankcase Oil Pick-Up Tube at the the Tube Insertion Hole in the bottom of the Oil Pump and at the Metal Support and Hold Down Bracket and carefully extract the Tube. Note that there are Bolt Retainers that will keep the two 10 MM Fasteners in place with the Tube and set these items aside.

To Remove the Harmonic Balancer... THE ONLY TOOL THAT WILL WORK is the OTC Model #6667 (6) Piece Kit consisting of the Three Prong Tool with a Female threaded center and three, free-moving pinned arms that will allow you to adjust them into the groove positions shaped into the arms of the Harmonic Balancer. Next it the Hollow Center Pin with Fine Threads that require the application of High Pressure Grease to ease the stress of the thread-lines that will have to pull outwards with around 700 Fit Lbs of Torque in very tiny turning increments. To that is added a set of Heat Treated Steel Pins of varied lengths to allow this Kit a wider variety of applications.

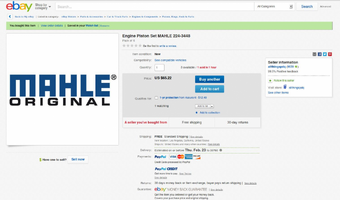

Using the intermediate sized pin that gets stuck down inside the threaded bolt...the Puller Tool is guided with the pin entering to quite a depth inside of the Hollow Crankshaft and allowing the rounded end to seat in the Hollow Dead Center of the Crankshaft...and then the Three Arms must be held in position while inserting the Square end of a 3/8” Ratchet with an adjustable handle into the Square Hollow end of the Bolt… and by tightening slowly until all Three Arms have a good grip on the underside portions of the Harmonic Balancer… as the Tool Snugs up… place your free hand underneath the Harmonic Balancer and gradually tighten down the Black Center Bolt and you will feel the action working as the Puller slide the HB towards you. This will take a few minutes and finally...the Harmonic Balancer will drop off the end of the Crankshaft … right into the palm of your hand… Just… Like … That. Now… set the HB and OTC Tool aside for later inspection and clean-up… (Later on… I’ll be installing a Brand New Harmonic Balancer).

Son now on to removing the Timing Chain Cover … Use the 10MM X 3/8” Drive Socket and Ratchet and slowly loosen all of the Perimeter Fasteners and Bag them as you go along… But keep Two Bolts out to thread into Threaded Bolt Holes located towards the Bottom Outer Flange hollow rectangular pockets and after remove the last Smaller 8MM Fastener roughly centered in the near the middle of the Timing Chain Cover. Then gradually tighten the Two Bolts down until the GM Gray OEM RTV seal adhesion is broken and while being careful not to drop the Front Cover… gently pry it loose by holding the outer edges (these are very sharp and can cut you) and gently lift the cover off of the front of the Engine.

Well … I think that is enough activity for one day … I’m am done in right now and I’m going to try using some Tiger Balm Red on my lower left ankle and the arch of my foot to see if it works to bring down the damned swelling. The videos that follow on from here are the Best onces I have seen on this part of the repair and should be downloaded and saved for repeat viewing for the great information and GM OEM Part Numbers they provide for this job.

This Video shows the OTC Special Harmonic Balancer Puller Tool in Demonstration Action:

And Big Props go out here to Carlos Diaz for his Epic Set of Videos on the Bravada Repair to R&R the Entire Front Components of the GM 4.2L Engine and Replace the Fan Clutch, the Water Pump AND Most Importantly… the Harmonic Balancer, too:

Part 1

Not Available on Youtube….

This last video shows a Disaster in The Making from a different VOP if the Crankshaft Bolt should ever come LOOSE:

https://www.youtube.com/watch?v=nH1yRLZJw5Y

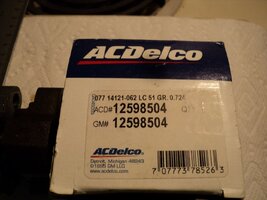

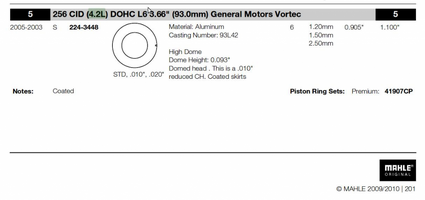

I’m pretty banged upright now… so I might need a few days to “Aggregate My Fecal Material” before moving on with the disassembly of the Timing Chain Set, The Timing Chain Guides, The Timing Chain Tensioner and the VVT Cam Phaser Sprocket, Timing Chain and Intake Sprocket. I will also have to do a dedicated post later that covers Cleaning up all of the Internal Engine areas using GM TEC as well. The R&R of the Engine Head will the “Last But Not Least” of these tasks before re-assembling everything with as many new components, gaskets and sealers as possible to get this engine “Ready for the Road...” Its surprising how clean this motor is inside...I really wish I had an accurate mileage on the Motor to show what one looks like when it “Ages Well”...All In All...THIS Really was a Pretty Damned Good Day!

Much More to Follow…

http://s557.photobucket.com/user/60...NEREPAIR/HARMONICBALANCEREMOVAL?sort=3&page=1