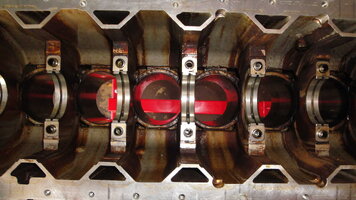

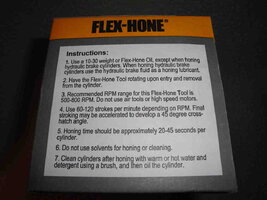

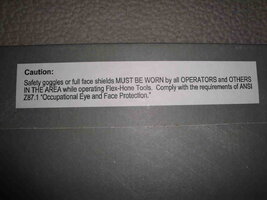

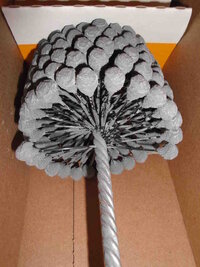

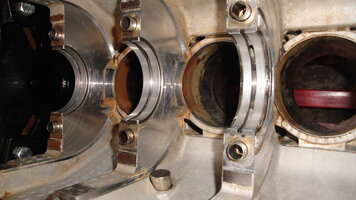

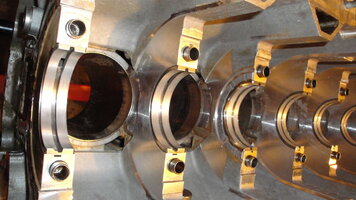

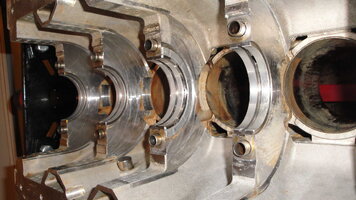

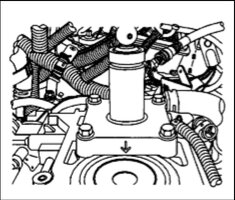

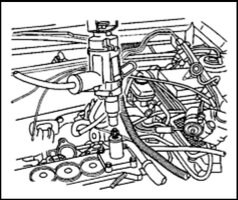

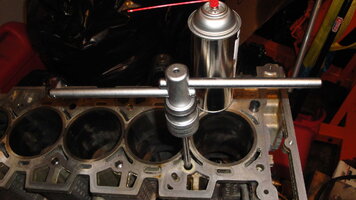

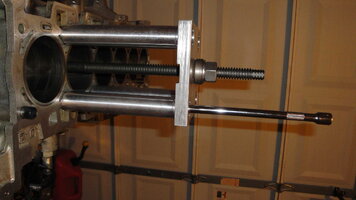

Well… After waiting damned near a full month… The 95 MM Flex-Hone Tool has arrived… and it seems a good time to mention that if you get this deep inside of your engine and after looking over all of the cylinders in your engine… you decide to do it the justice necessary by performing the Hone Out … These procedures should not give you the jitters any more than doing any of the other difficult tasks that have brought you this far along. The Beauty of the Flex-Hone is that unlike the complicated, gimbaled stones fixed inside of a huge Sunnen Boring Machine with oceans of coolant lubrication pouring inside such as used in the local Machine Shops… This tool is by far more gentle and forgiving:

http://s557.photobucket.com/user/60...BLAZERENGINEREPAIR/FLEXHONE95MM?sort=3&page=1

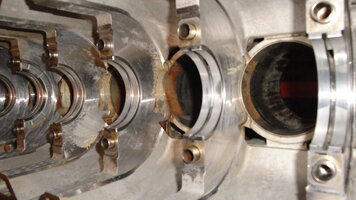

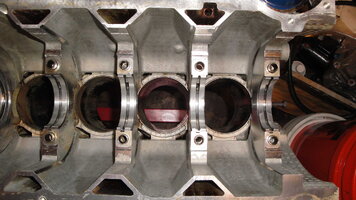

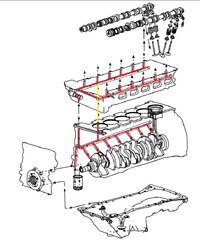

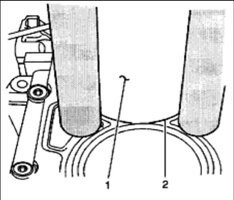

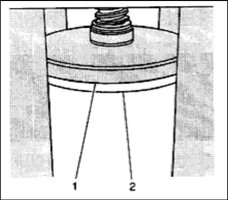

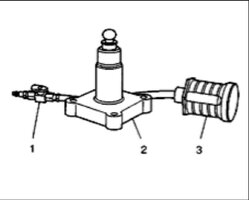

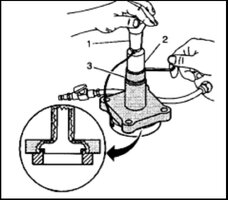

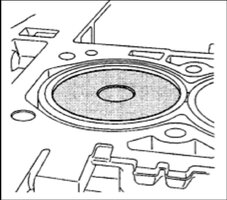

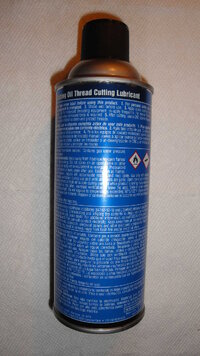

The design of the individual Carbide Nodules mounted on so many Flexible Nylon Stalks woven into central shaft of this tool means that as long as you align the tool essentially in the middle of the cylinder bore and start it turning before you move it down into each cylinder… The Carbide on Stalk design behaves as a Self-Centering device. Thus, it will take the worry out of any requirements for pre-mounting either the Engine Block or the Drill Head to any particular relationship between one another. You just have to properly prepare using either the requisite Flex-Hone Honing Oil that allows the removed metal particles to remain in suspension a little better… but Plain Old Organic 30 Weight Motor Oil will work just as well. It is NOT necessary to over-coat either the Cylinders or the Flex-Hone Tool with these lubricants… as the Hone will work Better if you are parsimonious with the stuff.

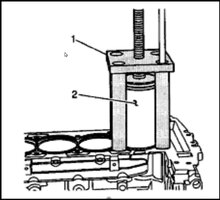

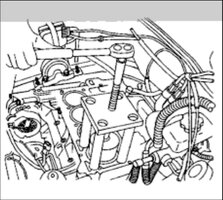

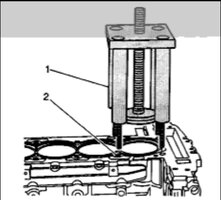

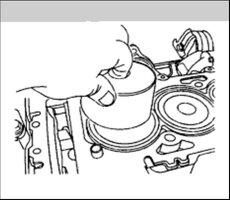

In the case of working the magic of this device on the GM Atlas 4.2L Engine… I’ll just tilt the block on the Engine Stand to about a 45 Angle, so that I won’t have to position my wrist in an odd way to negotiate my Big Drill in and out of each cylinder straight up and down at a right angle to the ground. I will only do a 10 Second Count at one in-out stroke per second when working each Cylinder to ensure doing the minimum amount of Metal Removal necessary to achieve a uniformly prepared surface inside each one.

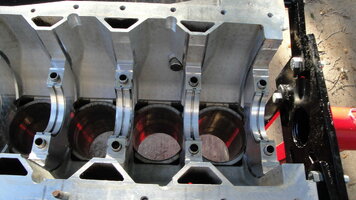

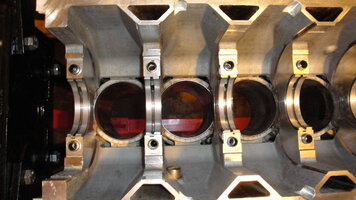

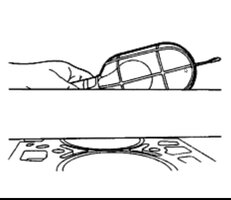

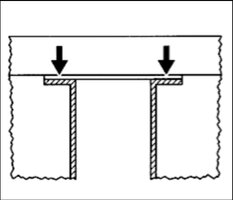

I will also have applied Blue Painters Tape and Plastic coverings to all of the openings inside the Engine Block to protect the Open Journals and Oil Galleries from having any Oil contaminated with Metal Particles and Abrasives from getting inside of those places when such can so easily be prevented. These areas will need to be wiped down with Lacquer Thinner or Acetone and covered with removable tape. I like the idea of working discretely; and by that I mean… using the following steps for each individual cylinder and NOT trying to perform these actions on all (6) cylinders at the same time:

(1) Clean off all surfaces of the upper head with Lacquer Thinner or Acetone and use Blue Painter’s Tape to cover all Bolt, Oiling and Coolant Holes.

(2) Clean off all lower engine block Surfaces, Bolt Holes and Crankshaft Journal openings and cover them with Blue Painter’s Tape and Plastic Coverings.

(3) Use a small amount of Flex-Hone Oil and Hone out One Cylinder at a Time.

(4) Wipe out that Cylinder Clean of Oil saturated with Carbide and Metal Particles.

(5) Wash out that Cylinder with Hot Water and Soap &Flex-Hone Plastic Brush (Wash, Rinse...Repeat).

(6) Wipe out that Cylinder with non-fiber shedding Cloths until No Metal Residue remains.

(7) Coat down that Cylinder with WD-40 (NOT OIL!) to Prevent Rust.

(8) Cover and Tape that Cylinder Head Opening with Saran Wrap to Keep Out Contamination.

(9) Perform these tasks for All Six Cylinders and then clean up the Lower Block of any Residues.

(10) Wipe down ALL surfaces inside the Lower Engine Block with Lacquer Thinner or Acetone.

After doing this ... and Chasing and Cleaning Out All of the Bolt Holes… The Engine Block will be Ready for Re-Assembly.

http://s557.photobucket.com/user/60...BLAZERENGINEREPAIR/FLEXHONE95MM?sort=3&page=1

The design of the individual Carbide Nodules mounted on so many Flexible Nylon Stalks woven into central shaft of this tool means that as long as you align the tool essentially in the middle of the cylinder bore and start it turning before you move it down into each cylinder… The Carbide on Stalk design behaves as a Self-Centering device. Thus, it will take the worry out of any requirements for pre-mounting either the Engine Block or the Drill Head to any particular relationship between one another. You just have to properly prepare using either the requisite Flex-Hone Honing Oil that allows the removed metal particles to remain in suspension a little better… but Plain Old Organic 30 Weight Motor Oil will work just as well. It is NOT necessary to over-coat either the Cylinders or the Flex-Hone Tool with these lubricants… as the Hone will work Better if you are parsimonious with the stuff.

In the case of working the magic of this device on the GM Atlas 4.2L Engine… I’ll just tilt the block on the Engine Stand to about a 45 Angle, so that I won’t have to position my wrist in an odd way to negotiate my Big Drill in and out of each cylinder straight up and down at a right angle to the ground. I will only do a 10 Second Count at one in-out stroke per second when working each Cylinder to ensure doing the minimum amount of Metal Removal necessary to achieve a uniformly prepared surface inside each one.

I will also have applied Blue Painters Tape and Plastic coverings to all of the openings inside the Engine Block to protect the Open Journals and Oil Galleries from having any Oil contaminated with Metal Particles and Abrasives from getting inside of those places when such can so easily be prevented. These areas will need to be wiped down with Lacquer Thinner or Acetone and covered with removable tape. I like the idea of working discretely; and by that I mean… using the following steps for each individual cylinder and NOT trying to perform these actions on all (6) cylinders at the same time:

(1) Clean off all surfaces of the upper head with Lacquer Thinner or Acetone and use Blue Painter’s Tape to cover all Bolt, Oiling and Coolant Holes.

(2) Clean off all lower engine block Surfaces, Bolt Holes and Crankshaft Journal openings and cover them with Blue Painter’s Tape and Plastic Coverings.

(3) Use a small amount of Flex-Hone Oil and Hone out One Cylinder at a Time.

(4) Wipe out that Cylinder Clean of Oil saturated with Carbide and Metal Particles.

(5) Wash out that Cylinder with Hot Water and Soap &Flex-Hone Plastic Brush (Wash, Rinse...Repeat).

(6) Wipe out that Cylinder with non-fiber shedding Cloths until No Metal Residue remains.

(7) Coat down that Cylinder with WD-40 (NOT OIL!) to Prevent Rust.

(8) Cover and Tape that Cylinder Head Opening with Saran Wrap to Keep Out Contamination.

(9) Perform these tasks for All Six Cylinders and then clean up the Lower Block of any Residues.

(10) Wipe down ALL surfaces inside the Lower Engine Block with Lacquer Thinner or Acetone.

After doing this ... and Chasing and Cleaning Out All of the Bolt Holes… The Engine Block will be Ready for Re-Assembly.

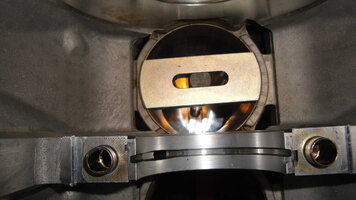

Nah but seriously, that was my OCD... I had to make sure. I re-checked the torque probably 10 times after I put on that mark too.

Nah but seriously, that was my OCD... I had to make sure. I re-checked the torque probably 10 times after I put on that mark too.