Hi All, Foremost, I want to thank everyone for going to such detail on the Class 2 serial data for GM trucks.

Buy I need a little help with sending some "commands" to the modules first a little background information (I want to go in detail in my own thread),

A few yes back, I bought a Chevrolet Avalanche II from 2005 equipped with OnStar, but unfortunately this does not work in The Netherlands, So I have been planning on how to overcome this problem at first I wanted to emulate button presses by connecting to the buttons itself on the HVAC unit for example,

But I came across "Bypass modules" that can control existing features by using the Class 2

So I thought if after market devices can do this, then I would be able to do so too.

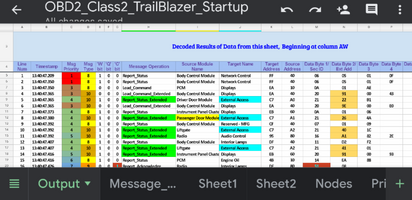

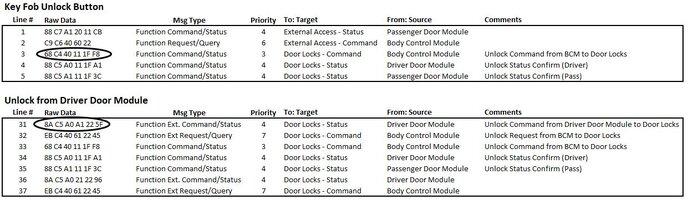

After a lot of time reading online (including this thread) and trying to understand the j1850 protocol, I started to probe around in the console of the ELM327 and got the easy stuff working pretty quickly just by sniff the traffic for example locking and unlocking the doors:

68 C4 97 -> 11 00 01 UNLOCK DRIVER

-> 11 1F 1F LOCK

-> 11 00 1E UNLOCK ALL

(note, I used the OnStar address, so I don't have duplicate addresses on the bus)

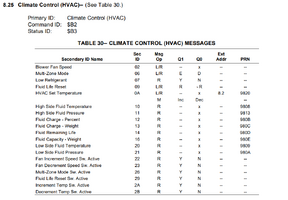

But here is where I get stuck, I Would like to turn on the HVAC, but I don't really understand how to build the "message"

If I take a look on

J2178-4 page 23 it talks about Primary ID, Command ID, Status ID: and then a table describing the different "functions" I would do the following, thinking the message type should be 10 priority 3, But I am not sure if this is correct :

Set the header >

AT SH 6A B2 F1

Send message > 0A ?? ?? Then I am lost. (0A should be Set temp)

I hope someone can point me in the right direction