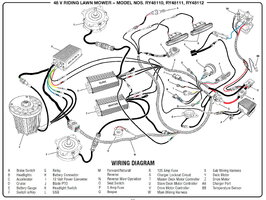

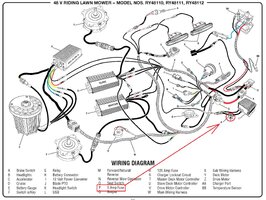

For any of those in the "Curious Crowd" still riding the fence because of certain YT Videos mentioning 'sudden, inexplicable stoppages' while Mowing Along on the Ryobi Model# RM480E "RELM" (Riding Electric Lawn Mower)...THIS Video coming from a very intrepid "Aussie" will cover some of his interesting observations and describe some simple solutions if you find yourself facing any of these temporary impediments towards getting your RELM to finish the job of giving you "A Well Manicured, Properly Cut Lawn":

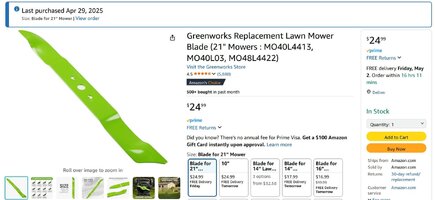

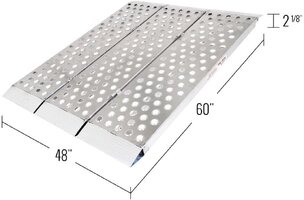

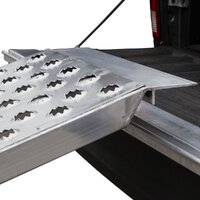

It follows on that in some instances, it will either be necessary to completely remove the Lower Double Blade Cutting Deck to easily perform the R&R of the Twin 20" Blades. If not... then elevating the RELM can become necessary... and... can be a bit tricky if not done with an eye towards caution and care... and risk injuring the Owner in the process. @Blckshdw has already posted his own cleverly conceived AUTO RAMP and Floor Jack solution as a safe lifting arrangement inside of his Garage.

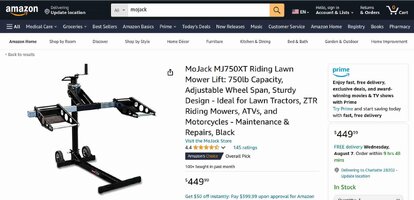

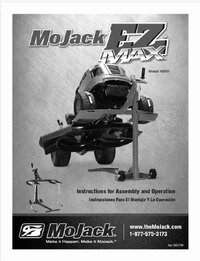

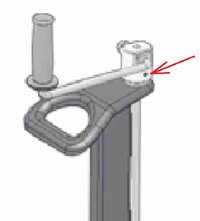

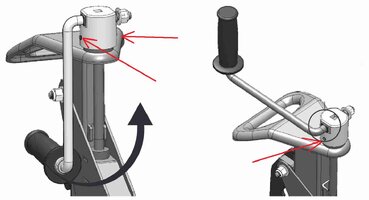

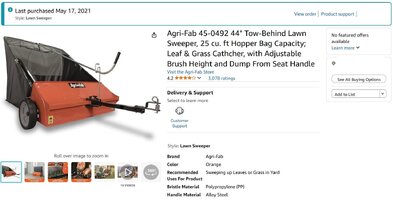

I'm taking his idea a step further by investing in a "MOJACK" which is this Collapsible, Hand Crank-able Heavy Mower Lift that slides under the Two Front Wheels as a Tractor-Mower Jacking Stand that can help whenever changing either the Twin Blades... or the 80W-90 GBO (Gear Box Oil) in that Hard To Access under-belly at the Rear of The RELM.

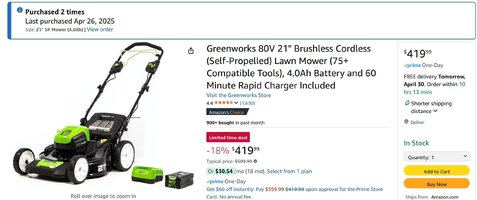

There IS a Less Expensive Version...Here:

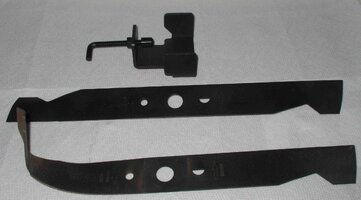

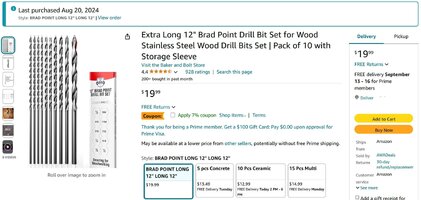

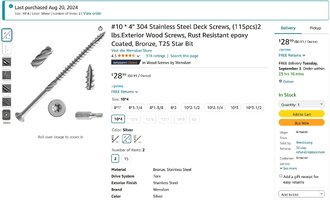

When I ordered this RELM Jack Stand off of Amazon, I added in a Hand-Held Lawn Mower Blade Sharpener that can be dragged along the tired Blade Edges and quickly renew their sharpness... without having to resort to either Grinding or Filing:

It follows on that in some instances, it will either be necessary to completely remove the Lower Double Blade Cutting Deck to easily perform the R&R of the Twin 20" Blades. If not... then elevating the RELM can become necessary... and... can be a bit tricky if not done with an eye towards caution and care... and risk injuring the Owner in the process. @Blckshdw has already posted his own cleverly conceived AUTO RAMP and Floor Jack solution as a safe lifting arrangement inside of his Garage.

I'm taking his idea a step further by investing in a "MOJACK" which is this Collapsible, Hand Crank-able Heavy Mower Lift that slides under the Two Front Wheels as a Tractor-Mower Jacking Stand that can help whenever changing either the Twin Blades... or the 80W-90 GBO (Gear Box Oil) in that Hard To Access under-belly at the Rear of The RELM.

There IS a Less Expensive Version...Here:

When I ordered this RELM Jack Stand off of Amazon, I added in a Hand-Held Lawn Mower Blade Sharpener that can be dragged along the tired Blade Edges and quickly renew their sharpness... without having to resort to either Grinding or Filing:

Last edited:

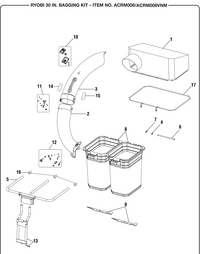

moment. Right behind where the chute goes, is a choke point. Between the caked on clippings, choke point, and new clippings without an exit point, that's probably what's bogging down that side of the action when I hit tall or thick grass, which tends to happen when I'm close to the lake. May try to rig up something with some twine that would allow me to raise the chute as needed to fit the mower through the shed door.

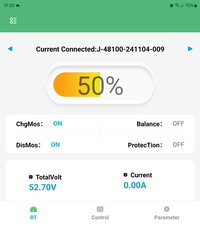

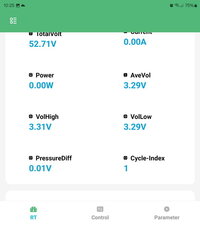

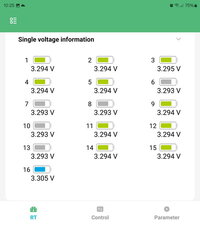

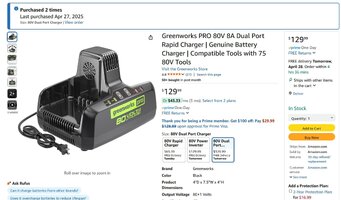

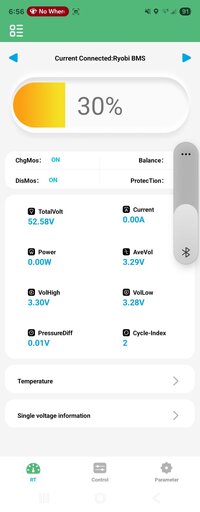

moment. Right behind where the chute goes, is a choke point. Between the caked on clippings, choke point, and new clippings without an exit point, that's probably what's bogging down that side of the action when I hit tall or thick grass, which tends to happen when I'm close to the lake. May try to rig up something with some twine that would allow me to raise the chute as needed to fit the mower through the shed door.  This will probably be the last summer for these batteries, will have to make the switch to LiFePo4 before next year. 3 of the 4 current batteries are 7 years old, so I've gotten my money's worth out of them. Will be a bit of a pain if I have to do my property in split shifts, but it is what it is...

This will probably be the last summer for these batteries, will have to make the switch to LiFePo4 before next year. 3 of the 4 current batteries are 7 years old, so I've gotten my money's worth out of them. Will be a bit of a pain if I have to do my property in split shifts, but it is what it is...

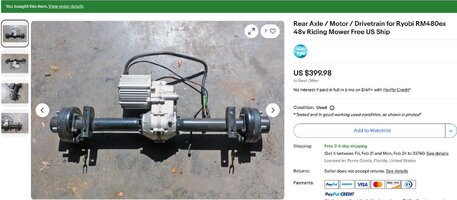

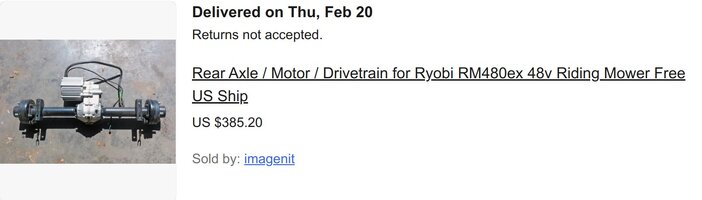

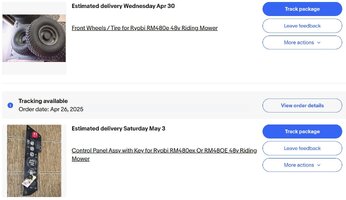

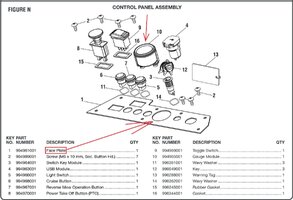

) When it came down to my problem being either the computer or the drive motor, I asked them if the motor was available on it's own, or if the transaxle had to be bought too, since there was no single part number in their list. They said you had to get both, so I was quite thankful I only needed the computer.

) When it came down to my problem being either the computer or the drive motor, I asked them if the motor was available on it's own, or if the transaxle had to be bought too, since there was no single part number in their list. They said you had to get both, so I was quite thankful I only needed the computer.