- Sep 24, 2012

- 71

Hi all,

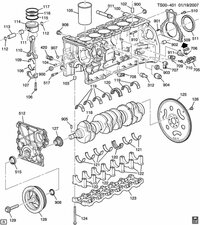

I have a 2002 Trailblazer Short Wheel Base 2WD 4.2L L6 Engine and I about to replace the leaking crankshaft front seal of my ride and I order new seal (Part Number: 89017621) new bolt (Part Number: 11609792) and new Serpentine Belt (Part Number: 12593774).

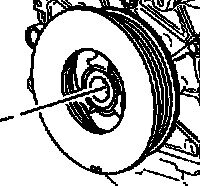

Maybe I need to replace the harmonic balancer (Part Number: 12571619) as well.

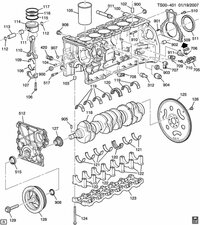

I see on here and on YouTube that a washer behind the crankshaft (Part Number: 12573950) (Number 906 on the pic below) have to be replace.

But the washer and the harmonic balancer are discontinue by GM and are not making any more.

Now there are a 2nd design harmonic balancer (Part Number: 12578069), seal (Part Number: 89017622) and washer (Part Number: 12578073)

My question is:

I have a 2002 Trailblazer Short Wheel Base 2WD 4.2L L6 Engine and I about to replace the leaking crankshaft front seal of my ride and I order new seal (Part Number: 89017621) new bolt (Part Number: 11609792) and new Serpentine Belt (Part Number: 12593774).

Maybe I need to replace the harmonic balancer (Part Number: 12571619) as well.

I see on here and on YouTube that a washer behind the crankshaft (Part Number: 12573950) (Number 906 on the pic below) have to be replace.

But the washer and the harmonic balancer are discontinue by GM and are not making any more.

Now there are a 2nd design harmonic balancer (Part Number: 12578069), seal (Part Number: 89017622) and washer (Part Number: 12578073)

My question is:

- Can I replace the 1st design seal and bolt without replace the washer behind the harmonic balancer???

- Can I replace all the 1st design to the 2nd design set mention above on a 1st design crankshaft????