This is the last of several articles during my work to replace the timing chain and tensioner.

How to replace the I6 timing chain and tensioner.

Difficulty (out of 5): 8 (I'm not kidding)

Tools required: Assortment of wrenches, ratchets, extensions, screw drivers. Socket sizes: 7mm, 8mm, 10mm, 11mm (or 7/16), 13mm, 14mm, 15mm, 17mm, 18mm, 21mm. Hammer, pry bar, long punch or drift, slide hammer with screw attachment.

Time required (removal and install): I don't really know

First of all, I would rather set my truck on fire than do this again. It was an exercise in frustration. It took me 1 and half months to do mine due to just life getting in the way, work, weather (I don't have a garage), broken tools and injury when I cut my hand open while working on it by tripping and falling on something sharp.

I elected to replace the chain, guide shoes and gears along with the chain tensioner just to be sure. My engine was "knocking" irregularly at the top front at idle

Use these instructions at your own risk and sanity.

.

.

EDIT: Re-reading this, I remembered that my phaser was damaged and I had to replace it later on because of the way I installed it. While torquing the bolt, use a wrench on the hex on the exhaust camshaft to hold it in place otherwise you will overextend the phaser and damage it. If reusing your old one, you should also use a wrench while removing the bolt.

How to replace the I6 timing chain and tensioner.

Difficulty (out of 5): 8 (I'm not kidding)

Tools required: Assortment of wrenches, ratchets, extensions, screw drivers. Socket sizes: 7mm, 8mm, 10mm, 11mm (or 7/16), 13mm, 14mm, 15mm, 17mm, 18mm, 21mm. Hammer, pry bar, long punch or drift, slide hammer with screw attachment.

Time required (removal and install): I don't really know

First of all, I would rather set my truck on fire than do this again. It was an exercise in frustration. It took me 1 and half months to do mine due to just life getting in the way, work, weather (I don't have a garage), broken tools and injury when I cut my hand open while working on it by tripping and falling on something sharp.

I elected to replace the chain, guide shoes and gears along with the chain tensioner just to be sure. My engine was "knocking" irregularly at the top front at idle

Use these instructions at your own risk and sanity.

- Remove the intake manifold and valve cover

- Remove the oil pan

- Drain the cooling system

- Remove the cooling fan and shroud

- Remove the water pump

- Remove the belt tensioner and idler pulley (now is a good time to check their condition, especially the bearings)

- Remove the #1 spark plug and put a screwdriver in it to help you determine top dead center

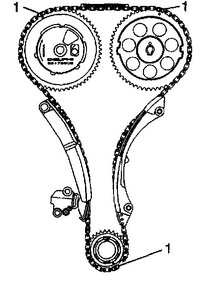

- Turn the engine using the harmonic balancer bolt clockwise until it's at top dead center and that the timing marks on the camshaft gears and chain are lined up. There is a mark on each gear and there are dark links on the chain that must be lined up. Another indicator is that the work "Delphi" on the camshaft phaser is horizontal with the head.

- Remove the harmonic balancer bolt. An impact wrench and socket should work if available but that bolt is on there with a lot of torque. You could put a large screwdriver in an intake gear hole to prevent it from moving while using a socket and very long breaker bar. You might have to extend it with a bar.

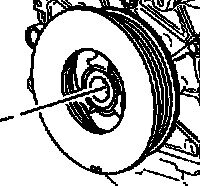

- Pull the harmonic balancer with a puller. Depending on which balancer you have, you may need a special Spent-Moore tool to pull. If you have an early 2002 model and your balancer looks like there is a large thick ring steel plate on the front of it like in this picture, then you will need Kent-Moore tool J 44226 to pull it.

- If you have a "normal" looking balancer like this one, then a 3 jaw gear puller should work.

I say should because this was the most difficult part of the job. It kicked my ass for more than 2 weeks. Broke two gear pullers and another heavy duty one kept slipping off. I bought another specialized one from Amazon: OTC 6667 Harmonic Balancer Puller . Good thing Amazon has a great return policy because I broke it using a breaker bar on the bolt. That balancer was not coming off! After I got the replacement puller, I used the torches to heat the crap out of it and it finally came off. When I went to my local U-Pull yard to get another, it came right off without hardly any issues or a lot of torque on the puller at all. Go figure.

I say should because this was the most difficult part of the job. It kicked my ass for more than 2 weeks. Broke two gear pullers and another heavy duty one kept slipping off. I bought another specialized one from Amazon: OTC 6667 Harmonic Balancer Puller . Good thing Amazon has a great return policy because I broke it using a breaker bar on the bolt. That balancer was not coming off! After I got the replacement puller, I used the torches to heat the crap out of it and it finally came off. When I went to my local U-Pull yard to get another, it came right off without hardly any issues or a lot of torque on the puller at all. Go figure. - Remove all the bolts holding the front timing cover. The small one in the middle may break, like it did for me. You should be at this point:

Also, it was very evident that my chain tensioner was not its job:

Also, it was very evident that my chain tensioner was not its job:

- With the screwdriver still in the camshaft gear, loosen the camshaft phaser and intake camshaft gear bolts.

- Remove the chain tensioner by removing the two bolts

- Remove the chain tensioner guide shoe and the other guide shoe. To access the bolt to remove it and the other shoe, remove this plug (now you know what it's for):

- Remove the upper chain guide located between the two camshafts

- Remove the camshaft phaser and intake camshaft. Unhook the chain from the crankshaft gear and pull the chain off

- There is a very thin spacer/washer on the crank snout in front of the crank gear. Pull it off and carefully set aside.

- Pull the crank gear. No puller required.

- When installing the new chain tensioner, you might need to install it with one bolt first and then the other while twisting it into place. Mine was tight with the new chain and shoes

- When installing the exhaust cam phaser, you have to be sure it's turned clockwise. While torquing down the bolt, it will turn itself in the right direction.

- Double and triple check that the chain is installed correctly with the marks on the gears and dark chain links lined up:

- The cam phaser bolt torque is 18 ft. lbs + 135 degrees rotation

- The intake cam gear bolt torque is 15 ft. lbs + 100 degrees rotation

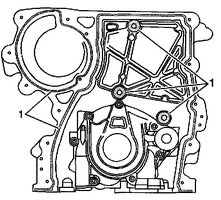

- The timing cover should be cleaned and resist the temptation to turn the oil pump as it must be aligned with the the notches in the crank gear. Apply silicone sealant (I used Permatex Ultra Grey) in a bead on the sealing surface as well as the three standoffs and around the water pump hole.

- Do not forget to replace the crank seal and oil pump passage seal:

- The harmonic balancer needs a shitload of torque. It's 110 ft. lbs + another 180 degrees rotation. For that final 180, I used a breaker bar with another bar added to it and guesstimated the degrees. I've never torqued anything that much before. I used the Kent-Moore tool (which I didn't need) to hold the balancer in place with another breaker bar. I wouldn't use the cam gear for this one.You might have to get somebody to hold it at the flywheel.

.

.EDIT: Re-reading this, I remembered that my phaser was damaged and I had to replace it later on because of the way I installed it. While torquing the bolt, use a wrench on the hex on the exhaust camshaft to hold it in place otherwise you will overextend the phaser and damage it. If reusing your old one, you should also use a wrench while removing the bolt.

Last edited: