A short time ago I posted a new pid I discovered for the Fan Speed of a 4.2 in a 2002 Trailblazer. It was properly suggested by MRRSM that I repost that information here so here I am. It is possible that this is my first original post!

I have been spending a great deal of time fiddling with these PIDs of late and have additional informations that I will post on this thread.

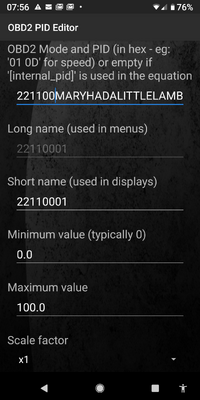

So as posted elsewhere the PID for Fan Speed to enter into Torque extended PIDs is 22162B (I confirmed only on a 2002 4.2). 22 being the mode or service and 162B the actual PID. Header should be set to "Auto" (cAsE sEnSiTiVe) and the equation is "A * 16". Spaces here don't matter. Units are RPM and Scale is x1.

Since that other post I have discovered that if one adds an "01" the the end of these extended PIDs the Torque app will receive the data quicker from the PCM as Torque won't need to cycle through formats seeking an answer from the PCM. I snooped the Class 2 bus while using Torque and found that with the "header" left blank many extended pids fail. When set to "Auto" (CasE sEnSiTiVe) Torque first sends the PID as entered in the extended PID definition and with many of the PIDs the PCM essentially rejects the request. Torque sends the same request again and is again rejected. Then Torque adds the "01" to the end of the PID, as in this case would be 22162B01, and bingo, the PCM answers with the data requested on the first request, speeding up the original startup at least. At first look I believe once Torque gets the answer it was seeking it remembers the format for the duration of that session but not further. You can see this using the test button in Torque while connected to your vehicle. Without the "01" appended there is a noticeable delay in the initial response time.

I have been spending a great deal of time fiddling with these PIDs of late and have additional informations that I will post on this thread.

So as posted elsewhere the PID for Fan Speed to enter into Torque extended PIDs is 22162B (I confirmed only on a 2002 4.2). 22 being the mode or service and 162B the actual PID. Header should be set to "Auto" (cAsE sEnSiTiVe) and the equation is "A * 16". Spaces here don't matter. Units are RPM and Scale is x1.

Since that other post I have discovered that if one adds an "01" the the end of these extended PIDs the Torque app will receive the data quicker from the PCM as Torque won't need to cycle through formats seeking an answer from the PCM. I snooped the Class 2 bus while using Torque and found that with the "header" left blank many extended pids fail. When set to "Auto" (CasE sEnSiTiVe) Torque first sends the PID as entered in the extended PID definition and with many of the PIDs the PCM essentially rejects the request. Torque sends the same request again and is again rejected. Then Torque adds the "01" to the end of the PID, as in this case would be 22162B01, and bingo, the PCM answers with the data requested on the first request, speeding up the original startup at least. At first look I believe once Torque gets the answer it was seeking it remembers the format for the duration of that session but not further. You can see this using the test button in Torque while connected to your vehicle. Without the "01" appended there is a noticeable delay in the initial response time.