You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cranks but won't start

- Thread starter Dave347

- Start date

christo829

Member

When you first turn te key to the run position (not start), do you hear the fuel pump cycle for about two or three seconds?

If not, either the fuel pump itself is dead or it's not getting any power. Do you have a multi-meter? No fuel pump could also be

the power circuit feeding it (including the relay), or the signal not being sent to power it in the first place. Ignition switch is a common

failure point in these trucks, and I see you already did that. Did you make sure the gear teeth were aligned right?

Mooseman has manuals and such, and there are wiring diagrams in there, as well as troubleshooting lists.

If the fuel pump primes up, it might still be under pressured (if you don't have a fuel pressure gauge, they can be rented from some auto

parts stores), or there may be a problem with the fuel pressure regulator. There's a vacuum port on the intake resonator thatties to the

FPR. See if you smell any fuel in that. You shouldn't.

I'm sure someone will pop in with more ideas.

Good Luck!

Chris

If not, either the fuel pump itself is dead or it's not getting any power. Do you have a multi-meter? No fuel pump could also be

the power circuit feeding it (including the relay), or the signal not being sent to power it in the first place. Ignition switch is a common

failure point in these trucks, and I see you already did that. Did you make sure the gear teeth were aligned right?

Mooseman has manuals and such, and there are wiring diagrams in there, as well as troubleshooting lists.

If the fuel pump primes up, it might still be under pressured (if you don't have a fuel pressure gauge, they can be rented from some auto

parts stores), or there may be a problem with the fuel pressure regulator. There's a vacuum port on the intake resonator thatties to the

FPR. See if you smell any fuel in that. You shouldn't.

I'm sure someone will pop in with more ideas.

Good Luck!

Chris

IllogicTC

Member

- Dec 30, 2013

- 3,452

You sure it's on the resonator? My 2005 has the following connections:

2x 10mm bolts to secure the right side

2x Large hoses w/ hose clamps to mount intake air hoses

1x Snug-fit hose, front-right, mounts to the valve cover

I don't see an FPR vacuum tube anywhere on my resonator. Maybe it's a year-by-year thing and earlier years have it, I don't know.

I know there's a hose that snug-fits on to the left-front side of the resonator but I was under the impression that was for a different purpose since I don't have one.

2x 10mm bolts to secure the right side

2x Large hoses w/ hose clamps to mount intake air hoses

1x Snug-fit hose, front-right, mounts to the valve cover

I don't see an FPR vacuum tube anywhere on my resonator. Maybe it's a year-by-year thing and earlier years have it, I don't know.

I know there's a hose that snug-fits on to the left-front side of the resonator but I was under the impression that was for a different purpose since I don't have one.

christo829

Member

Post #4 in this thread:

http://gmtnation.com/f25/fuel-smell-under-hood-9340/

The Roadie supplied the image.

Might be a year thing. I've got it on my 04.

Cheers-

Chris

http://gmtnation.com/f25/fuel-smell-under-hood-9340/

The Roadie supplied the image.

Might be a year thing. I've got it on my 04.

Cheers-

Chris

Classic flowcharting of this has three initial categories. Fuel, air spark. Fuel: check fuel pressure, listen for fuel pump, spray starting fluid into the intake. Air: observe throttle body butterfly plate with the resonator removed. Spark: check coil-related fuses, Wiring harness after the ignition switch, pull coil and plug to observe spark.

the roadie said:Classic flowcharting of this has three initial categories. Fuel, air spark. Fuel: check fuel pressure, listen for fuel pump, spray starting fluid into the intake. Air: observe throttle body butterfly plate with the resonator removed. Spark: check coil-related fuses, Wiring harness after the ignition switch, pull coil and plug to observe spark.

I've got the Envoy in with a no start. I've read most of the post at other forums as well as here so instead of starting a new thread with pretty much the same responses I thought I could keep coming here to go over all posts and maybe eliminate guess work and parts swaps. When it came in it was a crank no start but wasn't sure about the complaint if it was a stall then no start or parked then no start. Cold/warm/hot/parked for five mins etc. I checked for a engine light-on but don't remember if it stayed while cranking. Checked fuel level-full. Checked for codes-none and no recent code clearing and monitors test complete. Checked fuel pressure-none. Cycled the key a few times-still no fuel psi. Smacked the tank while cranking-no psi. Energized fuel pump relay with scantool-no click felt at relay. Swapped relay then cranked-got fuel psi. Idled engine for 2 hours-no stall and key restarted every 15mins-kept restarting. Replaced relay-start and drove 15miles-no stall or failure to start. Customer came to get car-would not start. Removed relay and then back in-starts. I suspect the fuse box lead tension is the problem or my pump harness has internal break. I've put way too much time into it because I've been babysitting it hoping to catch a mysterious flicker on instrument panel and recording data up to the stall but it never does. I'm going to run a ground to the diag connector then read amps to the fuel pump relay from the pcm. Hope something shows up. I hope this helps others with this problem. Mine seems to be a pretty hard find and I'll put up what I found to fix it.

Texan said:I have experience this on other GM cars in my family. The wiring underneath the vehicle

going to the fuel pump has a "weather pack" connection. Corrosion on the contacts.

Solution, contact cleaner and dialect grease.

Hi Texan I've never heard of weather pack connection/connectors but if I see it I might recognize it. The owner is a bit hyper concerned about his envoy. Me I'm not worried about it. He did add some more info to the history of the truck. Six months ago it stalled and wouldn't start the first five times he tried but it started on the sixth. Then after that it had a erratic fuel level reading and to the dealer he went after five months. They mentioned the recall and he had the "fuel sensor" replaced. I had words about him not mentioning this to me at his initial write up because he drove the truck for five months not knowing how much gas he had and we all know that running out of gas or low fuel level sucking of air can damage your pump. You might get away with it a few times but the damage is done. I told him that had I known that the tank was recently removed and the pump module reinstalled I would have sent him back there and for him to contact the service manager to resolve his concern. I mean they took a pump out of a tank with a questionable level sensor knowing of his stalling and not starting then not even recommend a pump to be safe? That was wrong. I'm the service manager/shop foreman of my shop and I would have offered it at my cost as a courtesy. It's not his fault the part failed and his lack of automotive knowledge is why he comes to me. I have no il-will to him, the dealer should have made it known to him that the pump is expiring now's the time to replace it while they were there for the sender as a safe guard. Today I got that whole speech from him saying he gave me such and such dollars($200 for 10hrs of diag)and it wasn't fixed how would I feel if it was me? I told him that I would try to understand the tech. I never said it was fixed and did not want him to take it. I explained again he has a intermittent problem and that it happened prior to coming to my shop. I made all test explanations clear and why the cost for a relay and oil switch but not duplicate the no start. I took that labor hit which is triple the parts cost. Not to jump back in time a bit but after that whole speech I had to set him straight about the dealer was just in his tank and the pump was not replaced and their claim that the fuel pump and fuel level sensor are not related was dead wrong. I was not giving him bad info but he needed to hear me and where I stood at the losing end without clear communication or history. He never mentioned the repeated stall over a six month period(he said twice)that occurred with a inaccurate fuel level sensor. He calmed down and agreed for the most part that he should have mentioned it and I understood that he may not thought it to be of relevance. I explain all that during write up when I can. So my next test I needed to do was stress his fuel pump and circuit. And I stressed his pump today in two ways one is with my gauge connected at a cold start idle I released the pressure from the gauge back into his tank with a ten foot hose then I let it run two hours and set rpm's it 2k and release the pressure again. We were getting air bubbles in the clear release hose. Later the gauge pressure dropped with the truck off. The pressure drops only after a full warm-up then shut down. I had my gauge on it overnite and this morning it was zero. If I prime the pump cold then pull the key the pressure remains above 50psi. Not out of the woods yet but I'm getting there. Tomorrow I'll check it again but at this point I'm not being rushed from Jim. I think we're on the same page and I'm on his side.

Texan

Member

- Jan 14, 2014

- 622

The "weather pack" connector is what some people/manufacturer call the electrical connecters/plugs

used on the exterior of a car body, under hood or under body. The one I am referring to is the one

used for the fuel pump/fuel gauge under the car near the gas tank. I have seen them not make

good constant contact, and work intermittently. Just a suggestion.

used on the exterior of a car body, under hood or under body. The one I am referring to is the one

used for the fuel pump/fuel gauge under the car near the gas tank. I have seen them not make

good constant contact, and work intermittently. Just a suggestion.

triz said:Fuel pump to me would be the most common failure I can think of. But usually you can hear it prime when your turn the key. If you don't there you go.

Hi triz, Just because you don't hear the pump should you replace it. Sometimes you have to recheck and confirm it's functioning as it should. If the fuel rail has enough pressure and the engine is cranked over it can start then as the rail pressure drops it will energize the relay and some fuel pump circuits have no relay at all. It's on a duty cycle or pulse width modulation that powers the pump by varying on time in cycles. The on and off time will go with demand. Need more fuel your computer increases the on time. Less fuel less on time. That's on some import cars. The envoy has many things that to me seem over thought and can't understand the thinking. It has what's called a oil switch which should be called the "if its fixed then break it don't" We all know oil pressure up good down bad. Now take that thought then adjust you mind to this. That switch sends info to your engines computer without the engine running. The switch fails your engine will not start. It bypass the request to energize the fuel pump relay. Its backwards it should not be read on start up if the information can only be used for engine running (oil pressure is above zero). The engine needs to be running to lose oil pressure but that switch makes no sense. Reading oil pressure while cranking does not compute in my head. The has to be cyphoned from the pan its going to be a instant 40psi. Switch fails no start. Purpose not a clue.

IllogicTC

Member

- Dec 30, 2013

- 3,452

I just thought of something... why, oh why, has none of us mentioned the possibility of the fuel filter yet? 02-04 had a fuel filter in-line with the pipe running it up-front, some were mounted by the front driveshaft, some just ahead of the fuel tank. The look is reminiscent of a "canister" style capacitor, being a cylinder with two "prongs" that come out at one end. Has two hoses connected of course, with 90-degree elbows at the actual fitting point, and is secured with a simple strap.

If you have the means to test fuel pressure, good pressure in the back and crap pressure at the rail could be a pointer toward this.

If you have the means to test fuel pressure, good pressure in the back and crap pressure at the rail could be a pointer toward this.

Hypnotoad

Member

- Dec 5, 2011

- 1,584

IllogicTC said:I just thought of something... why, oh why, has none of us mentioned the possibility of the fuel filter yet? 02-04 had a fuel filter in-line with the pipe running it up-front, some were mounted by the front driveshaft, some just ahead of the fuel tank. The look is reminiscent of a "canister" style capacitor, being a cylinder with two "prongs" that come out at one end. Has two hoses connected of course, with 90-degree elbows at the actual fitting point, and is secured with a simple strap.

If you have the means to test fuel pressure, good pressure in the back and crap pressure at the rail could be a pointer toward this.

Because the OP hasn't even figured out if it's a fuel, air, or spark issue. Time to get down to the basics of auto mechanics.

triz

Member

- Apr 22, 2013

- 746

By me saying if he did not hear the pump, its me saying that would be a good place to start as far as troubleshooting. I would follow Roadie post on checking to make sure your getting delivery of fuel. +1 on getting to the basics of mechanics. I don't think the OP at the moment needs to break out any special tools yet.

Texan

Member

- Jan 14, 2014

- 622

wingnut said:Hi triz, Just because you don't hear the pump should you replace it. Sometimes you have to recheck and confirm it's functioning as it should. If the fuel rail has enough pressure and the engine is cranked over it can start then as the rail pressure drops it will energize the relay and some fuel pump circuits have no relay at all. It's on a duty cycle or pulse width modulation that powers the pump by varying on time in cycles. The on and off time will go with demand. Need more fuel your computer increases the on time. Less fuel less on time. That's on some import cars. The envoy has many things that to me seem over thought and can't understand the thinking. It has what's called a oil switch which should be called the "if its fixed then break it don't" We all know oil pressure up good down bad. Now take that thought then adjust you mind to this. That switch sends info to your engines computer without the engine running. The switch fails your engine will not start. It bypass the request to energize the fuel pump relay. Its backwards it should not be read on start up if the information can only be used for engine running (oil pressure is above zero). The engine needs to be running to lose oil pressure but that switch makes no sense. Reading oil pressure while cranking does not compute in my head. The has to be cyphoned from the pan its going to be a instant 40psi. Switch fails no start. Purpose not a clue.

I can understand your feelings. The "oil switch" is a weird design, shuts down engine if pressure drops below 10 or 12 psi.

But that prevents some drivers from burning up the engine. I use to always wonder why they did not put audible alarms on "idiot lights".

The I6 engine has a fuel pressure regulator, which I think has a return line to the tank. Some cars have a dead end fuel rail and

use the duty cycle or PWM method to regulate pressure.

IllogicTC

Member

- Dec 30, 2013

- 3,452

Texan said:I can understand your feelings. The "oil switch" is a weird design, shuts down engine if pressure drops below 10 or 12 psi.

Are you certain? DIC-equipped models tell you "LOW OIL PRESSURE / STOP ENGINE." Tells the owner what to do rather than forcing the engine off which would radically alter the driving characteristics when you drop pressure at 70MPH on the Interstate.

Texan

Member

- Jan 14, 2014

- 622

IllogicTC said:Are you certain? DIC-equipped models tell you "LOW OIL PRESSURE / STOP ENGINE." Tells the owner what to do rather than forcing the engine off which would radically alter the driving characteristics when you drop pressure at 70MPH on the Interstate.

I am not certain, but thought I read that in another thread. I agree that it could be a real problem on the highway.

I do not have DIC and have had no problems with my instrument cluster.

IllogicTC

Member

- Dec 30, 2013

- 3,452

Texan said:I am not certain, but thought I read that in another thread. I agree that it could be a real problem on the highway.

I do not have DIC and have had no problems with my instrument cluster.

If you find that thread again, let them know I have a sale going on wiper blade sharpeners.

wingnut said:Hi triz, Just because you don't hear the pump should you replace it. Sometimes you have to recheck and confirm it's functioning as it should. If the fuel rail has enough pressure and the engine is cranked over it can start then as the rail pressure drops it will energize the relay and some fuel pump circuits have no relay at all. It's on a duty cycle or pulse width modulation that powers the pump by varying on time in cycles. The on and off time will go with demand. Need more fuel your computer increases the on time. Less fuel less on time. That's on some import cars. The envoy has many things that to me seem over thought and can't understand the thinking. It has what's called a oil switch which should be called the "if its fixed then break it don't" We all know oil pressure up good down bad. Now take that thought then adjust you mind to this. That switch sends info to your engines computer without the engine running. The switch fails your engine will not start. It bypass the request to energize the fuel pump relay. Its backwards it should not be read on start up if the information can only be used for engine running (oil pressure is above zero). The engine needs to be running to lose oil pressure but that switch makes no sense. Reading oil pressure while cranking does not compute in my head. The has to be cyphoned from the pan its going to be a instant 40psi. Switch fails no start. Purpose not a clue.

I'm amazed at the recent post here. I've answered most of the guestions for my situation and I know this was not my thread so I'm not trying to take over the thread. I've looked at most and some seem to spark my curiousity. Triz I agree the pump was not making noise but you have to go deeper and take a look at what's going on. PCM may not send a fuel pump request if it has no tach signal. Some cars actually look at fuel pressure readings before cranking and if it's above a minumum it can start the engine then power the fuel pump relay, this lessen's the load on the battery. IllogicTC today's fuel filters rarely cause a no-start without having very noticeable symptoms. No power or engine lean codes. You can check engine fuel trim numbers for raised long term fuel trim data and see if fuel is being added to correct lean running engines. No indications were there. Toad I'm not sure what the OP has done or could have done but in my instance I've seen this before and you can't check the spark with the COP ignition system(not easily or without a scope or coil sensing rod,yes that's what I think it's called checkout PICO scope GM Coil testing) but I did check for a rpm from engine data during cranking(254rpm). So seeing tach reference I assumed a fuel demand would be sent. Now I feel I've lost a few followers when I checked for fuel pressure and not circuit power. With a tach reference and a good crank speed I know I have a good battery. Sometimes you can crank the engine but the battery can't power up the ignition. You can tell because the engine cranks fast for maybe a second or two then it slows alot and you get the clicking from the solenoid. After that initial try the system needs to repower up stored voltages for solenoid coils and many things that have stored voltages including the PCM. So my experience leads me to verify for fuel. Also prior to that I had already checked Jim's truck for codes read the fuel level gauge and had a tach signal. In the engine data there was no fuel pressure reading to go by so I put my gauge on at the rail to see what it was which was zero on two key cycles. When I pulled the relay(there is no fuel pump fuse it's controlled and powered by the PCM) and checked voltages it read battery voltage but it was noisey meaning the voltage was not stable. That was a sign to check what else is in line with the relay but data was incomplete on the wiring schematic. I was afraid when I put a different relay in it would start and it did. I tried the original also with a successful restart. That is not a clear fix to me. I felt 80% certain it had to be a contact or connection fault and hoped it was not a intermittent pump failure. They take the longest to confirm and have many symptom and test variables. No two pumps have the same test failure readings and symptoms. It's all acceptable ranges because we can't build components with exacting spec guidelines. In other words we don't try to narrow the variables it's whatever works. KNBlazer are you asking two questions? It does have a SES light. It comes on during bulb check and goes out while running so the PCM was good. No codes were found in history,current,or pending. And yes the dealer replaced fuel level sensor. Any fuel pressure regulated system has a return and systems without a regulator have a fuel pressure and temp sensor. Those system's use a PWM to adjust pressure more closely to the demand. IllogicTC(2) That info is sent to the DIC by the PCM. From what I understand the info or DIC commands are formulated by the PCM and that some of the info don't read what's really happening but a generic reading to please the eye because it always reads a good number. Uphill battle without some part failure to give me a direction to go in. Hopefully it will happen tomorrow.

IllogicTC

Member

- Dec 30, 2013

- 3,452

wingnut said:IllogicTC(2) That info is sent to the DIC by the PCM. From what I understand the info or DIC commands are formulated by the PCM and that some of the info don't read what's really happening but a generic reading to please the eye because it always reads a good number.

Yes, but if it follows below the switch's threshold the gauge will suddenly drop to zero, your Check Gauges light will illuminate, and if DIC-equipped, it will flash that warning message, all along with a nice quick chiming (about the speed used when leaving your headlights on). The switch requires I believe >=12PSI to satisfy the condition for "good" pressure, which is kind of a lie but I guess they're the engineers and know what pressure is absolute minimum for satisfactory lubrication.

I'm trying to read the post, but it's like the Great Wall of Text. Is there any way you could edit it and break it up into smaller paragraphs?

IllogicTC said:Yes, but if it follows below the switch's threshold the gauge will suddenly drop to zero, your Check Gauges light will illuminate, and if DIC-equipped, it will flash that warning message, all along with a nice quick chiming (about the speed used when leaving your headlights on). The switch requires I believe >=12PSI to satisfy the condition for "good" pressure, which is kind of a lie but I guess they're the engineers and know what pressure is absolute minimum for satisfactory lubrication.

I'm trying to read the post, but it's like the Great Wall of Text. Is there any way you could edit it and break it up into smaller paragraphs?

Sorry about the content. Your correct about the gauge and chime. My mention about the gauge and function was about how the PCM uses it at different times that make...... really pointless use of info. What happens during start up is not as important as when the engine is running. The PCM powers the relay to prime the fuel system after that the oil switch takes over to keep the pump powered. The PCM has momentary control but if the oil switch fails the PCM sees that and kills the circuit. That seems questionable. Loss of oil pressure while running? Set off a light or chime and message but don't kill the fuel system. How can you check for oil pressure if the engine doesn't run?

wingnut said:Sorry about the content. Your correct about the gauge and chime. My mention about the gauge and function was about how the PCM uses it at different times that make...... really pointless use of info. What happens during start up is not as important as when the engine is running. The PCM powers the relay to prime the fuel system after that the oil switch takes over to keep the pump powered. The PCM has momentary control but if the oil switch fails the PCM sees that and kills the circuit. That seems questionable. Loss of oil pressure while running? Set off a light or chime and message but don't kill the fuel system. How can you check for oil pressure if the engine doesn't run?

Here's the latest round in the Envoy saga part 12 million. IllogicTC sorry about the million word response. I guess I should have spaced between answers to other post. Like this

Yeah that'll work.

I made the leap today. I had to see the inner demon I suspected inside the fuse box. The box can be separated by loosening the anchor bolts,remove the positive lead for the main fuse, and releasing the side catch hooks. Once apart I found what I like to call a "thermal incident" at the lead for the fuel pump relay. Also while checking the box pins I could see some discoloring from poor contact. I can't get to the circuit board sealed inside the box. Without knowing what it looks like I recommended a new box but at $400 it was too much so option B. Clean the leads and adjust contact tension. Hopefully it will work. But without replacing the box it's all I can do. Can't bypass the box it appears to have more than one component to that pin. Tomorrow should have it back together to be all it can be. Maybe.....

wingnut said:Here's the latest round in the Envoy saga part 12 million. IllogicTC sorry about the million word response. I guess I should have spaced between answers to other post. Like this

Yeah that'll work.

I made the leap today. I had to see the inner demon I suspected inside the fuse box. The box can be separated by loosening the anchor bolts,remove the positive lead for the main fuse, and releasing the side catch hooks. Once apart I found what I like to call a "thermal incident" at the lead for the fuel pump relay. Also while checking the box pins I could see some discoloring from poor contact. I can't get to the circuit board sealed inside the box. Without knowing what it looks like I recommended a new box but at $400 it was too much so option B. Clean the leads and adjust contact tension. Hopefully it will work. But without replacing the box it's all I can do. Can't bypass the box it appears to have more than one component to that pin. Tomorrow should have it back together to be all it can be. Maybe.....

Hey guys I finished the Envoy but all was not well. I thought I would have a easy finish the following day but it only ended with more hidden gems. I had the connector apart removed the darken cavity lead. I begin to loosen the anchor bolts of the two remaining connector blocks. I loosen them but the connector had no give. Not one to keep prying at it I checked for anything that looked to be a lock but nothing. Moving the box for a clear view of the connector looking for movement I noticed a corner that was not flush to the box. I thought it to be a sign of uneven movement wedging the connector thus keeping it in place not allowing for easy removal. I ended up having to use the anchor pins to tap the connector out. The connector and box had some twist most likely from heat. I would say the box needed replaced and be done with however no other issues were apparent and the main issue was the fuel pump. After I got the connector off I seen no signs of excessive heat. I put it back together with a cleaned lead and increased pin to lead tension with a resolve to this problem or so I assumed.

Once together most of the way I chose to leave the box not fully locked together so I could verify the voltage at the suspected lead if needed. I started the engine and it stalled but I had noticed a check engine light on. I put the pressure back on to see if I had pressure I did so I tried again this time I felt a very noticeable vibration. On my Verus I found a #5 misfire. I pulled the coil and plug on #2 as well as five. Swapped the plug no change then I swapped the coil and the misfire move to number 2. I couldn't figure out how that happened. No single wire to the coils pass thru the box no wires to the PCM were not even touched at all. That made very little sense but I had a theory. The box. The heat was a sign. The box design to me has a flaw. The box has a contact flaw and because I was unable to see the internals I couldn't see the extent. I did recommend the box replacement prior to checking the leads. Jim would not see my point and say that the box looks fine. I had no evidence to convince him but I said my experience and instincts tell me this is the failure. I called him with my findings and the price for a new coil he of course had some words but I told him I did not charge for any diag of the coil or taking the box apart but these two findings points the box and my original recommendations. I gave him cost for the coil and I would prove my findings to him but I really was not going to keep chasing more problems for free. I put it outside so he could pick it up. I know he'll have more problems and hope he takes it to the dealer and see them side everything by blaming it on the previous tech. Now I change my opinion of past techs. Sometimes we're not allowed to fix cars if owners refuse to replace parts. How could I explain there is no failure guidelines and even the manufacturer has no easy outs. Failure guidelines in a dealer setting or shop is "try known good ECU" I'm happy it's gone and wished Jim the best. I plan on giving a follow up call. To all that have this complete series of post well your better listeners so to speak, you don't look for the quick answer and say "I knew that" to yourself. You have a genuine quest for understanding. I'm that way also and I don't like writing a novel for each car I fix but there are way too many different cars and problem cars and no two are ever the same and I mean ever.

IllogicTC

Member

- Dec 30, 2013

- 3,452

I appreciate the follow-up. A faulty connector could indeed throw all kinds of goofy crap your way, especially on the PCM since each connector has tons of wires. I understand there's no money in poking around everywhere for free when doing mechanical work is how you make a living, but it was nice of you to at least dig in a bit with diagnosis pro bono.

I'd bet with misfires "walking around," they'll do the normal test - swapping coil to one cylinder and spark plug to another. If nothing changes or it goes way off, I'm betting they'll do a leakdown test. Few people around here have had misfires and ended up with a bad leakdown test, and that very well may be his issue. If not, wiring and PCM, and especially when it comes to chasing down wiring and at a dealership his repair bill will rack up quick since they're usually not going to do a bit of "free" poking around first.

When you do the follow-up and if he tells you what's up, feel free to pass it along to us. All info is good info, and the documenting of a bad experience now could maybe help someone down the road.

I'd bet with misfires "walking around," they'll do the normal test - swapping coil to one cylinder and spark plug to another. If nothing changes or it goes way off, I'm betting they'll do a leakdown test. Few people around here have had misfires and ended up with a bad leakdown test, and that very well may be his issue. If not, wiring and PCM, and especially when it comes to chasing down wiring and at a dealership his repair bill will rack up quick since they're usually not going to do a bit of "free" poking around first.

When you do the follow-up and if he tells you what's up, feel free to pass it along to us. All info is good info, and the documenting of a bad experience now could maybe help someone down the road.

IllogicTC said:I appreciate the follow-up. A faulty connector could indeed throw all kinds of goofy crap your way, especially on the PCM since each connector has tons of wires. I understand there's no money in poking around everywhere for free when doing mechanical work is how you make a living, but it was nice of you to at least dig in a bit with diagnosis pro bono.

I'd bet with misfires "walking around," they'll do the normal test - swapping coil to one cylinder and spark plug to another. If nothing changes or it goes way off, I'm betting they'll do a leakdown test. Few people around here have had misfires and ended up with a bad leakdown test, and that very well may be his issue. If not, wiring and PCM, and especially when it comes to chasing down wiring and at a dealership his repair bill will rack up quick since they're usually not going to do a bit of "free" poking around first.

When you do the follow-up and if he tells you what's up, feel free to pass it along to us. All info is good info, and the documenting of a bad experience now could maybe help someone down the road.

Hi, I'm sure the dealer has the missfire scenario down. As far as the missfire on Jim's I found that fairly quick. I'm not sure about the leak down test if I swapped the coil and plug to #2 cylinder and it still misfired my next step would have been a injector having his fuel issue it may have lead to fuel rail blockage so I had that already in my possibility list. So a compression or leak down test was the third step.

Funny thing did happen I had a Trailblazer stop by the shop because the battery gave out. We put a new one in per request with no testing. I noticed all his gauges were off or pegged at full range. I looked at my helper and just laughed. I had him ask the owner and yes it came in that way. When we got it started it had the same low idle as Jim's so I know I fixed it but whatever took out the coil is anyone's guess. We'll have to wait and see but I'm not holding my breath. Thanks for following along.

coolride

Member

Yesterday it was fine, and this morning it cranks but won't start.

The ignition switch is acting funny. When it's turned to "start" the engine cranks fine. But when I let go of the switch, it doesn't spring back to the run position. The engine continues to crank by itself until I turn the switch back manually. I've never noticed that before.

Any ideas? It might have codes (I'll check later today.)

The ignition switch is acting funny. When it's turned to "start" the engine cranks fine. But when I let go of the switch, it doesn't spring back to the run position. The engine continues to crank by itself until I turn the switch back manually. I've never noticed that before.

Any ideas? It might have codes (I'll check later today.)

Last edited:

christo829

Member

The switch not returning sounds like a mechanical failure of the switch assembly.

There's a name for the function that keeps the starter going until the engine fires even

when the key has returned to "run", but I'm blanking on it at the moment. It's normal,

and may not have any interrelationship with your switch not returning to "run". Usually,

the engine has started by the time you pay attention to the switch position, so you'd

never notice that it will keep cranking even after you've released the key.

Good Luck!

Chris

There's a name for the function that keeps the starter going until the engine fires even

when the key has returned to "run", but I'm blanking on it at the moment. It's normal,

and may not have any interrelationship with your switch not returning to "run". Usually,

the engine has started by the time you pay attention to the switch position, so you'd

never notice that it will keep cranking even after you've released the key.

Good Luck!

Chris

coolride

Member

I checked for codes and there's none. Also, I do not hear the fuel pump.

I see a fuel pump relay listed (41) in the owner's manual, but not a fuel pump fuse.

I'll check the relay now.

I see a fuel pump relay listed (41) in the owner's manual, but not a fuel pump fuse.

I'll check the relay now.

coolride

Member

I inspected the relay. and the fuses listed in the owner's manual as "Ignition" A, B and E (34, 36, 22.) No problems there. What next?

I do own a fuel pressure gauge and a multi meter. Will check for spark tonight.

I do own a fuel pressure gauge and a multi meter. Will check for spark tonight.

Last edited:

To positively eliminate all of the potential PCM -BCM Electronic, Wiring, Bad Ignition Switch or Electrical component failure issues Please follow these procedures:

(1) Obtain a few cans of the inexpensive GUMOUT STARTER FLUID:

https://www.amazon.com/dp/B001GLSIKG/?tag=gmtnation-20

(2) Use the Spray Materials involved here with CAUTION... Always have a Fire Extinguisher on hand. These actions are best applied with the Vehicle parked in an open area. If working on the SUV inside a Garage... Open the Garage Door completely and Warn Away Family, Friends, Animals and Strangers ...and Keep Your Wits about you. DO NOT OVER-DO THE USE OF THIS STUFF!

(3) Pull the Fuel Pump Relay...Remember... You want to Test and Eliminate the aforesaid EE Components... NOT determine if the Fuel Pump will allow the Vehicle to Start-Run. Turn over the Engine to run momentarily and reduce any remaining Fuel Pressure inside the Fuel Lines for 10 or 15 Seconds.

(4) Remove the Air Plenum and detach the S/S Clamped Tube from its connection to the Throttle Body JUST ENOUGH to allow you to Squirt in the Starter Fluid. Use Short, Controlled Bursts.

(5) Immediately turn the Ignition Key and try to start the Engine. If the Motor Fires up Briefly... This will prove that the Cylinder Compression, Electronic PCM and Coil On Plug System Integrity works and that your In-Tank Fuel Pump may be FUBAR. Make the necessary arrangements to obtain the recommended ACDelco, Delphi or Bosch High Quality Version and plan out how perform the R&R accordingly.

NOTE:

MAKE CERTAIN THAT YOU HAVE ELIMINATED ANY CHANCE OF HAVING ANY BROKEN-DETACHED WIRES AND CONNECTORS TO AND FROM THE FUEL PUMP ...FIRST.

(6). If the Motor Does NOT Fire Up... return to the Diagnostic FAQ here at GMTN for the "No Start- No Crank" possible issues.

(1) Obtain a few cans of the inexpensive GUMOUT STARTER FLUID:

https://www.amazon.com/dp/B001GLSIKG/?tag=gmtnation-20

(2) Use the Spray Materials involved here with CAUTION... Always have a Fire Extinguisher on hand. These actions are best applied with the Vehicle parked in an open area. If working on the SUV inside a Garage... Open the Garage Door completely and Warn Away Family, Friends, Animals and Strangers ...and Keep Your Wits about you. DO NOT OVER-DO THE USE OF THIS STUFF!

(3) Pull the Fuel Pump Relay...Remember... You want to Test and Eliminate the aforesaid EE Components... NOT determine if the Fuel Pump will allow the Vehicle to Start-Run. Turn over the Engine to run momentarily and reduce any remaining Fuel Pressure inside the Fuel Lines for 10 or 15 Seconds.

(4) Remove the Air Plenum and detach the S/S Clamped Tube from its connection to the Throttle Body JUST ENOUGH to allow you to Squirt in the Starter Fluid. Use Short, Controlled Bursts.

(5) Immediately turn the Ignition Key and try to start the Engine. If the Motor Fires up Briefly... This will prove that the Cylinder Compression, Electronic PCM and Coil On Plug System Integrity works and that your In-Tank Fuel Pump may be FUBAR. Make the necessary arrangements to obtain the recommended ACDelco, Delphi or Bosch High Quality Version and plan out how perform the R&R accordingly.

NOTE:

MAKE CERTAIN THAT YOU HAVE ELIMINATED ANY CHANCE OF HAVING ANY BROKEN-DETACHED WIRES AND CONNECTORS TO AND FROM THE FUEL PUMP ...FIRST.

(6). If the Motor Does NOT Fire Up... return to the Diagnostic FAQ here at GMTN for the "No Start- No Crank" possible issues.

Last edited:

Mooseman

Moderator

I'd also be checking the ignition switch. It sure sounds like it has issues. Check that the fuel pump runs for a couple of seconds when you turn the key to RUN. If it doesn't that would be your issue (no fuel). Go from there.

Download the manuals from my signature link. They have the electrical schematics that you can follow for the testing of the different circuits.

Download the manuals from my signature link. They have the electrical schematics that you can follow for the testing of the different circuits.

coolride

Member

Today I was ready, with a can of starting fluid. But I disconnected the battery overnight so first job was to reconnect the neg. terminal. And of course I turned the ignition to "run," heard the fuel system pressurize, and the darn thing fired right up.

Yesterday, I saw a guy on youtube who suggested cutting the power for 24 hours so I thought "how could it hurt." I just scanned for codes again, and there's no codes.

Coincidental? Or is there something to cutting the power?

And yes, the ignition switch is working normally again.

Yesterday, I saw a guy on youtube who suggested cutting the power for 24 hours so I thought "how could it hurt." I just scanned for codes again, and there's no codes.

Coincidental? Or is there something to cutting the power?

And yes, the ignition switch is working normally again.

Last edited:

coolride

Member

It ran fine today for a few of errands. Then I went out for gas and it died on me at the pump. I sprayed some starting fluid into the intake and it did idle briefly.

I tried a dozen times to restart the engine. Then I disconnected the neg terminal and waited 15 minutes. I reconnected the battery and it fired up, and I drove it home.

I tried a dozen times to restart the engine. Then I disconnected the neg terminal and waited 15 minutes. I reconnected the battery and it fired up, and I drove it home.

Mooseman

Moderator

I'm thinking the fuel pump or the relay is failing. Carry a meter or test light with you and do some checks at the relay socket the next time it does it. Maybe the fact you disconnect the battery for 15 minutes just gives the pump or relay a rest. Also try banging on the bottom of the tank if the checks at the relay are good. Try jumping the relay to force the pump to work.

coolride

Member

This morning I did it right. I pulled the relay, and de-pressurized the fuel line. Then I added a short puff of starting fluid into the intake and the engine did then, briefly start and idle. (Thank you MRRSM for the procedure.)

Mooseman, I did swap some relays around and that had no effect.

Not sure where to start testing with the multi meter.

Mooseman, I did swap some relays around and that had no effect.

Not sure where to start testing with the multi meter.

Mooseman

Moderator

When it does fail to start and the pump won't prime, pull the relay and check to see if the PCM is sending the ground signal to activate the relay during the prime and while cranking. Also try to jump the relay and listen if the pump runs.

And while you are hovering over the Pin Insert points of the Relays... just know that they can occasionally SPREAD APART and the vibration of the running vehicle can cause the Relay to lose contact solidarity. @TJBaker57 once showed us that by giving the Relay Tines a slight "Twist" on each one to improve the contact surface area can allow the Relay to function again. Be judicious with the "Tine Torque' ...Please...

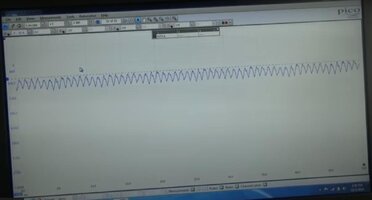

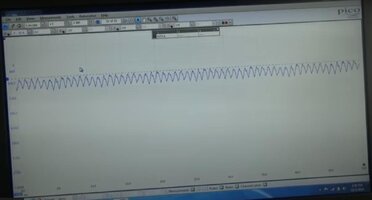

Also... Eric "O" from South Main Auto has shown us using his PICO Oscilloscope that each Commutator (8-12 of them ) inside of a Good Fuel pump creates and displays a steady, even oscillation patterns on screen as a reliable Wave Form:

Good Fuel Pump Wave Form:

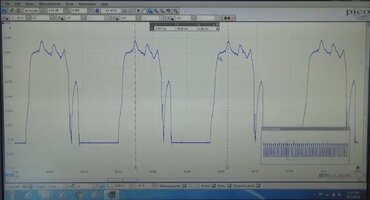

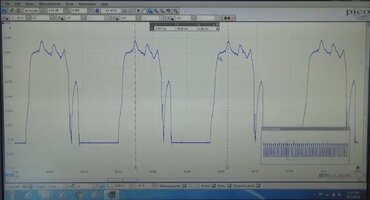

However, in the case of a Bad Fuel Pump...there will be a few Dead Spots in that pattern ...and if the Vehicle stops with the Fuel Pump Commutator situated in one of those "Valleys"...it will NOT want to Start.

Bad Fuel Pump Wave Form:

He mentioned that he was able to Start and Run the Vehicle to get it to his shop by using a Dead Blow Hammer and just Banging on the underside of the Fuel Tank to coax the Truck to Start. You might want to try this technique out using a Rubber Mallet and carry it with you until you nail down the issue if this technique works for you.

One other thing worth mentioning as an observation of your "15 Minute Delay"... is that whenever an Electric Motor suffers from a loss of even Commutator electrical flow... it can draw additional Amperage into the working portion as it tries to take up the slack from the ones that are NOT functioning and cause the Electric Motor to Over-Heat... even when submerged in Fuel. So it may very well be that your "15 Minute Wait" also allowed the Fuel Pump Electric Motor to Cool Down just enough in the interim to get back to "spinning and pumping" the Fuel. Just sayin'...

Also... Eric "O" from South Main Auto has shown us using his PICO Oscilloscope that each Commutator (8-12 of them ) inside of a Good Fuel pump creates and displays a steady, even oscillation patterns on screen as a reliable Wave Form:

Good Fuel Pump Wave Form:

However, in the case of a Bad Fuel Pump...there will be a few Dead Spots in that pattern ...and if the Vehicle stops with the Fuel Pump Commutator situated in one of those "Valleys"...it will NOT want to Start.

Bad Fuel Pump Wave Form:

He mentioned that he was able to Start and Run the Vehicle to get it to his shop by using a Dead Blow Hammer and just Banging on the underside of the Fuel Tank to coax the Truck to Start. You might want to try this technique out using a Rubber Mallet and carry it with you until you nail down the issue if this technique works for you.

One other thing worth mentioning as an observation of your "15 Minute Delay"... is that whenever an Electric Motor suffers from a loss of even Commutator electrical flow... it can draw additional Amperage into the working portion as it tries to take up the slack from the ones that are NOT functioning and cause the Electric Motor to Over-Heat... even when submerged in Fuel. So it may very well be that your "15 Minute Wait" also allowed the Fuel Pump Electric Motor to Cool Down just enough in the interim to get back to "spinning and pumping" the Fuel. Just sayin'...

Last edited:

coolride

Member

This morning I put the TB on jack stands (Craftsman,) and dropped the crossbar. I expected to see a fuel filter and a harness connector, but instead I saw none of that.

It's a bad picture, I must have been moving. I always put plywood between the frame and jack stands. Metal on metal gives me a bad vibe.

It's a bad picture, I must have been moving. I always put plywood between the frame and jack stands. Metal on metal gives me a bad vibe.

Last edited:

For your Year-Make-Model of SUV... The Fuel Pump and Fuel Filter dwell together in the Tank... (Nice of GM to make things like this so much EZR for us as time went on...Right?)

Take a peek at THIS Video for some more "Cranks-No Start" Troubleshooting Diagnostics (Skip the Lead Music & Welding Scene) and note that the VOP (Video Original Poster) ventures under the SUV on a High Lift to work on How to Test the Fuel Pump Circuit... and he finds something very interesting:

ScannerDanner... Shows "How To Test a Fuel Pump...WITHOUT Using a SCANNER... and instead using a "Light Probe"...Scope On A Rope. He also covers wire probing AT THE PUMP HARNESS:

Take a peek at THIS Video for some more "Cranks-No Start" Troubleshooting Diagnostics (Skip the Lead Music & Welding Scene) and note that the VOP (Video Original Poster) ventures under the SUV on a High Lift to work on How to Test the Fuel Pump Circuit... and he finds something very interesting:

ScannerDanner... Shows "How To Test a Fuel Pump...WITHOUT Using a SCANNER... and instead using a "Light Probe"...Scope On A Rope. He also covers wire probing AT THE PUMP HARNESS:

Last edited: