2003 GMC envoy 200,xxx miles

Bought this truck with over 6 codes lit up

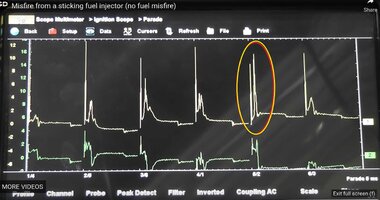

only issue was rough idle and misfire. P0449 p0300 p0134 p0135 p0154 p0442

What I fixed so far:

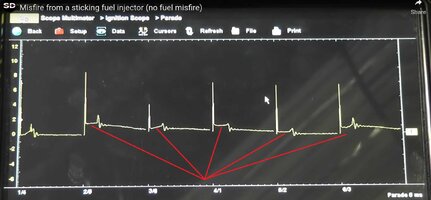

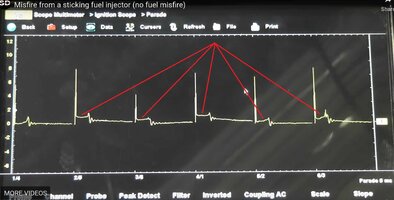

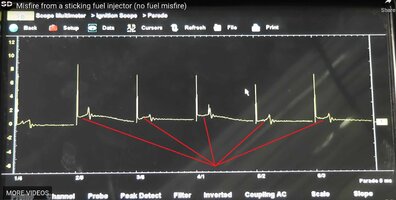

Injector bank 2 had a broken/ damaged wire (now I can hear all injector open and close)

Broken spark plug (#1) changed all driver side plugs still plan on charging the ones on the other side soon.

New plugs and seems like I’m getting spark from all wires.

Changed intake gasket and valve cover gaskets

New temperature sensor plug

New knock sensors and plugs.

Cleaned all injectors.

Now all the codes are gone. Except the random misfire code P0300.

New O2 sensors (previous owner had wired the O2 wrong)

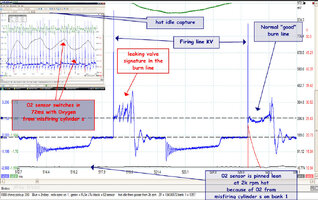

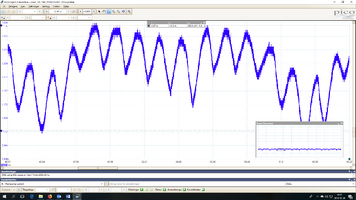

O2 sensors bank 1 stays around .2V (recently found out it goes down to 0v at 2000 rpm

Bank 2 runs around .800/.900 V (still have to pull spark plugs to figure out what’s going on on that side.

I’m new to diagnostics and stilll trying to wrap my head around all this so all the help is well needed thanks guys.

Seems like it misfire got worse and now it pops. This is not my daily but would keep trying as soon as I get back home from being on the road.

Bought this truck with over 6 codes lit up

only issue was rough idle and misfire. P0449 p0300 p0134 p0135 p0154 p0442

What I fixed so far:

Injector bank 2 had a broken/ damaged wire (now I can hear all injector open and close)

Broken spark plug (#1) changed all driver side plugs still plan on charging the ones on the other side soon.

New plugs and seems like I’m getting spark from all wires.

Changed intake gasket and valve cover gaskets

New temperature sensor plug

New knock sensors and plugs.

Cleaned all injectors.

Now all the codes are gone. Except the random misfire code P0300.

New O2 sensors (previous owner had wired the O2 wrong)

O2 sensors bank 1 stays around .2V (recently found out it goes down to 0v at 2000 rpm

Bank 2 runs around .800/.900 V (still have to pull spark plugs to figure out what’s going on on that side.

I’m new to diagnostics and stilll trying to wrap my head around all this so all the help is well needed thanks guys.

Seems like it misfire got worse and now it pops. This is not my daily but would keep trying as soon as I get back home from being on the road.