BuckeyeEvan said:

amazing thread.

amazing job you are doing!!!!!!

Thanks man I really appreciate it! I'm really glad that I had the opportunity to do all this and share my experiences with you guys! Not EVERYONE does head work.. I understand this. However, I think what all I've managed to post will show people what's really going on internally and what they can most certainly do to address it instead of wasting time and money only trying to guess at it!

Gentlemen... We have lift off..

We showed up at the shop around nine tonight and finished off around midnight. So all in all we've put in a total of 12 hours work. The head gave us a fight but after everything was removed correctly she lifted right up!

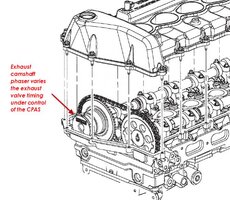

We started off with the crankshaft pulley and attempted to use a two-ton pulley remover. Our attempts with it were unsuccessful. We actually ended up bending our tool, but it makes no difference as autozone will still give me my money back for the rental regardless of it being broken or not. Still pretty funny though, we're going to reattempt it again later on because we'll have to get in behind it and reset the timing. Anywho, we decided to over-ride that option. We went with plan B and chose to remove the camshafts and guides. Then work our way to the headbolts. We broke three out of fourteen, but that's still pretty good considering I've heard horror stories from others with their headbolts. Once the headbolts were out we disconnected the wires from the rear of the head and then took out two additional sensors. The machine shop says that if we take the cams, guides and sensors out they'd charge me a bit less. So we made that happen. Very easy to do, I recall using a 10mm several times with it!

Additional notes for the night:

Removed cams and headbolts, three headbolts broke in the process.

Head lifted after all sensors were disconnected and guides were unscrewed. Left guide snapped.

Out of the six NGK iridium spark plugs I took out, only one was fouled out. Cylinder #4

We observed a large amount of carbon built up in the combustion chamber, piston walls however were clean!

Head gasket was on the verge of potentially blowing, caked with carbon, burnt in coloration.

Oil and water jackets were clean and clear.

Exhaust had a lot of carbon, intake however was clean and showed amazing burn patterns.

Cams that were taken out were lubricated with quaker oil as they will be sitting for a few days until the machine shop gives my upper cylinder head back.

--If you're going to remove the head, take the water pump out first so all that remains in the combustion chamber can drain!

Now it's off to the machine shop! This will be my last post for the next week and a half! Enjoy the pictures guys, I hope they bring you a new sense of hope when dealing with the head removal/internal issues that may cause misfires! -Lee