This 2002 TB with 72k miles has been running great and been very dependable for her. She is about 350 miles away right now and driving back tomorrow. Today, out of nowhere, at a stop light the engine died, like a light switch shut off. Not any notice and did not die like starving for fuel. She put in Park and immediately restarted and drove 20 miles back to where she is staying with no problems. History: Within last 2k miles: new GM iridium plugs, new GM air charge temp sensor in the air snorkel tube, new GM water pump and new GM thermostat/water outlet assembly, new GM ignition switch-there is a thread here about that journey. New GM fuel filter. Cleaned throttle bore and MAF.

This vehicle starts up immediately and runs smooth and strong and just today was the only hint at a problem. She did not even feel it die. She went to accel from a stop light when turned green, realized had died, put in park and cranked normally and started right back up and ran fine getting back.

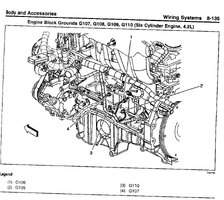

I do not suspect ignition coil because is not a misfire but I guess could be a ground for the ignition coil circuit. I told her to drive home tomorrow and keep an eye on all gauges. I also suspect a cam or crank sensor and will likely go ahead and do both anyway. have them in a cart at RA right now. Can anyone tell me the location for the ignition coils ground? Tell me any helpful hints for replacing the cam and crank sensors? Tell me about a similar "engine die at idle" problem and what was done to fix?

Thanks in advance.

This vehicle starts up immediately and runs smooth and strong and just today was the only hint at a problem. She did not even feel it die. She went to accel from a stop light when turned green, realized had died, put in park and cranked normally and started right back up and ran fine getting back.

I do not suspect ignition coil because is not a misfire but I guess could be a ground for the ignition coil circuit. I told her to drive home tomorrow and keep an eye on all gauges. I also suspect a cam or crank sensor and will likely go ahead and do both anyway. have them in a cart at RA right now. Can anyone tell me the location for the ignition coils ground? Tell me any helpful hints for replacing the cam and crank sensors? Tell me about a similar "engine die at idle" problem and what was done to fix?

Thanks in advance.