The truck developed this issue in early december but I left it as other things were "scheduled" plus the weather isn't always nice. Anyway, I started to look at this as the low speed abs is annoying and maybe it ain't good for the system (ABS) in the long term.

Read some threads on similar issues to get some ideas. Did some electrical tests (impedance and ac voltage). The resistances were around 1K, one slightly less and one slightly more. Spinning the wheel by hand gave me some voltage ... not a lot as trying to speed the wheels (with tire / rim off) doesn't really get much "spin". But It did generate some voltage from each. I listened to the hub while spin the rotor (brakes removed so no contact / rubbing). The spins wire quiet / smooth and didn't detect any roughness. I could not cause any "reflects" when with the tires on and trying angular "twist". I did notice that the driver's side seemed to be harder to spin (without wheel) compare to the passenger side.

I posted this thread when I did the hubs back when.

gmtnation.com

gmtnation.com

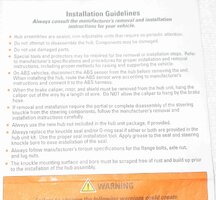

As you will have read, the passenger side hub was done twice as the replacement hub only lasted about 1 year (no name brand). I had kept one of the old hubs and used that as a replacement of the replacement. Everything has been fine since until this past few months.

I don't have a tech2 to read anything in terms of abs data. I have to still connect and do a cargage? ... app that can read codes for some of the non-engine units.

I am thinking that the initial replacement on the driver's side is now a problem due to its "stiffness" in the "spin test".... or is there some other component that could have contributed to the "binding" during the spin test and I am just gambling that one of the hubs is bad?

Thanks for any comments / ideas.

This should probably be moved to the technical section as opposed to the engine / drive train... sorry.

Read some threads on similar issues to get some ideas. Did some electrical tests (impedance and ac voltage). The resistances were around 1K, one slightly less and one slightly more. Spinning the wheel by hand gave me some voltage ... not a lot as trying to speed the wheels (with tire / rim off) doesn't really get much "spin". But It did generate some voltage from each. I listened to the hub while spin the rotor (brakes removed so no contact / rubbing). The spins wire quiet / smooth and didn't detect any roughness. I could not cause any "reflects" when with the tires on and trying angular "twist". I did notice that the driver's side seemed to be harder to spin (without wheel) compare to the passenger side.

I posted this thread when I did the hubs back when.

watch out... its a drone... not that kind of a drone..

My truck (2008 4.2 TB) has developed a drone. It becomes noticeable at about 40mph and up. It is coming from the front end. Its not dependent on engine rpm and shifting between D and 3rd causes no difference as does removing the gas. There is no detectable difference in cornering in terms...

As you will have read, the passenger side hub was done twice as the replacement hub only lasted about 1 year (no name brand). I had kept one of the old hubs and used that as a replacement of the replacement. Everything has been fine since until this past few months.

I don't have a tech2 to read anything in terms of abs data. I have to still connect and do a cargage? ... app that can read codes for some of the non-engine units.

I am thinking that the initial replacement on the driver's side is now a problem due to its "stiffness" in the "spin test".... or is there some other component that could have contributed to the "binding" during the spin test and I am just gambling that one of the hubs is bad?

Thanks for any comments / ideas.

This should probably be moved to the technical section as opposed to the engine / drive train... sorry.

Last edited: