2005 Chevy Trailblazer LT, 2-Door, 4WD, I6 4.2L engine

Won't start or turn over. No starter signal at starter relay but when jump relay will turn over but not start.

No check engine light. All instrument light on when first to key on the go out except battery & gauge warning light stay on. Gas gauge was working but now show MT and yellow gas warning light is on but tank over 3/4 full.

When leave key in on position for a while security lights come on

Dash lights, head light, heater, radio, turn signal, windows, wipers and everthing seems to work.

Normal code reader cannot comunicate with or read codes. But power to OBDII plug.

Snap-On scanner can read codes but only recognizes 10 systems and 8 codes with cleared and return. Snap-On Scanner will not Auto ID car and says Comm problem. Snap-On scanner can run run function test of lights, windows, power down, ect in Bode Control Module. Checked CIGAR fuse #13 under the hood and is good. Checked for battery voltage at the rear fuse block big red wire & 12 volts. All fuses in both fuse boxes look good.

Reconized Modules

1. Anti-lock Brakes - 0 codes

2. Airbag - 2 Codes

- U1000 Class 2 Data Link Fault (Current & History)

3. Body Control Module - 2 codes

- U1000 Loss of Class 2 Serial Communications

4. Door Module - Drive - 0 codes

5. Heating Air Conditioning - 2 codes

- U1000 Class 2 Data Link Fault (Current & History)

6. Instrument Panel Cluster - 0 codes

7. Lift Gate - 0codes

8. Passenger Presence System - 1 code

- U100 Class 2 Serial Communication Problem (Current)

9. Transfer Case - 1 code

- U100 Class 2 Serial Communication Problem (Current)

10. Door Module - Passenger - 0 codes (History)

Scap-On scanner says the following modules exist but can not communicate with or read any data from

1. Engine

2. Radio - Aftermarket

3. Seat module - driver

4. Theft Deterrent

5. Transmission

Past History

Has a occasional starting issue where would not start unless disconnected battery for 10 -15 minutes then would start properly again for a week or two. No codes found with normal code reader. Talked to Chevy Dealer who said needed to be towed in while in no start condition to read codes and diagnosis. Had spare BCM and had dealer program to car.

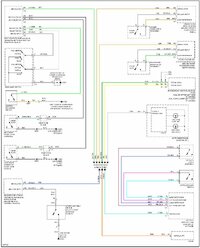

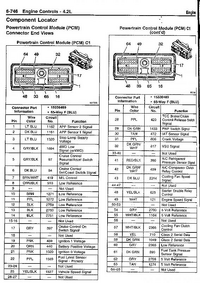

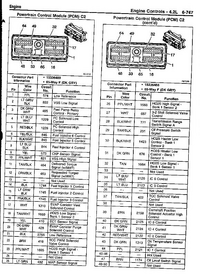

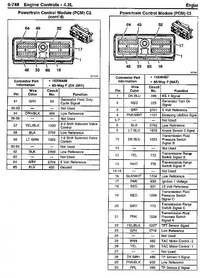

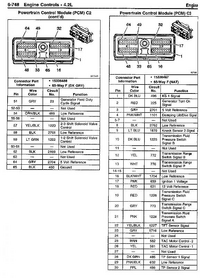

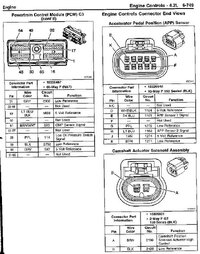

Home now and have access to my tools & test equipment. Need a step by step test to identify the electrical serial buss issue causes or eliminate possible causes. Searched but not much information found other than disconnect modules one at a time to check if one is going bad and corrupting the serial bus.

Thinking first step is to test all fuses with multi-meter. Then inspecting all wiring in engine compartment for mouse damage. Had a mouse build nest under air cleaner and chew thru some injection wiring last year.

Thanks, Jim

Won't start or turn over. No starter signal at starter relay but when jump relay will turn over but not start.

No check engine light. All instrument light on when first to key on the go out except battery & gauge warning light stay on. Gas gauge was working but now show MT and yellow gas warning light is on but tank over 3/4 full.

When leave key in on position for a while security lights come on

Dash lights, head light, heater, radio, turn signal, windows, wipers and everthing seems to work.

Normal code reader cannot comunicate with or read codes. But power to OBDII plug.

Snap-On scanner can read codes but only recognizes 10 systems and 8 codes with cleared and return. Snap-On Scanner will not Auto ID car and says Comm problem. Snap-On scanner can run run function test of lights, windows, power down, ect in Bode Control Module. Checked CIGAR fuse #13 under the hood and is good. Checked for battery voltage at the rear fuse block big red wire & 12 volts. All fuses in both fuse boxes look good.

Reconized Modules

1. Anti-lock Brakes - 0 codes

2. Airbag - 2 Codes

- U1000 Class 2 Data Link Fault (Current & History)

3. Body Control Module - 2 codes

- U1000 Loss of Class 2 Serial Communications

4. Door Module - Drive - 0 codes

5. Heating Air Conditioning - 2 codes

- U1000 Class 2 Data Link Fault (Current & History)

6. Instrument Panel Cluster - 0 codes

7. Lift Gate - 0codes

8. Passenger Presence System - 1 code

- U100 Class 2 Serial Communication Problem (Current)

9. Transfer Case - 1 code

- U100 Class 2 Serial Communication Problem (Current)

10. Door Module - Passenger - 0 codes (History)

Scap-On scanner says the following modules exist but can not communicate with or read any data from

1. Engine

2. Radio - Aftermarket

3. Seat module - driver

4. Theft Deterrent

5. Transmission

Past History

Has a occasional starting issue where would not start unless disconnected battery for 10 -15 minutes then would start properly again for a week or two. No codes found with normal code reader. Talked to Chevy Dealer who said needed to be towed in while in no start condition to read codes and diagnosis. Had spare BCM and had dealer program to car.

Home now and have access to my tools & test equipment. Need a step by step test to identify the electrical serial buss issue causes or eliminate possible causes. Searched but not much information found other than disconnect modules one at a time to check if one is going bad and corrupting the serial bus.

Thinking first step is to test all fuses with multi-meter. Then inspecting all wiring in engine compartment for mouse damage. Had a mouse build nest under air cleaner and chew thru some injection wiring last year.

Thanks, Jim

Last edited: