While you heal and get better over the next few days… I wanted to mention a bit more about the “Repair Balance Beam” this Damned Engine places us all upon when we start getting deeper inside of this unique power plant. On the one side ...you have me… and anyone else crazy enough to follow the cascade of actions that have marched my repair saga steadily from one thing towards another; ultimately knowing that I will eventually conquer the truck that crippled me and create a Bullet-Proof Motor … but at a greater cost in money and time.

On the other side of that Beam… you have

@Mooseman …and the other Good and Sensible Members, Ringing the Bell of Reason and Practicality; reminding you that “ If It Is Not Broken...Don’t Fix It...”. And right in the middle… You find Yourself ...Sitting rather nicely on top of a sound and sturdy Fulcrum that includes the right Skill Set and the great possibilities offered from having access to a 100 Square Foot Training Repair Shop, decently equipped with Tools, Chain Hoists and Friends in your class that can offer you the help you need to mightily speed your repairs along.

My thinking is that I should make some sound suggestions now and show you the images of the things that not only can be done while your Motor is bolted to an Engine Stand… but SHOULD be done while you have this Golden Opportunity of doing so. When this work is over and done… you will never want to take this Engine apart ever again and if you are clever now, you won’t have to think or worry about it ever again. And so on behalf of those “teetering” opposite my own precarious position on this Balance Beam… I’ll make this a very practical suggestion of a “Baker’s Dozen” that leans more in their favor than in mine:

(1) Unless you determine that you have loose Con-Rod Bearings… Leave Them Alone.

(2) Unless you find the Cylinders are way out of correct dimensions with Piston Scuffing… Leave Them Alone.

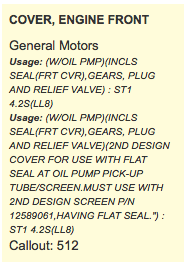

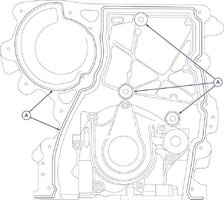

(3) While you have the Front Timing Chain Cover off of the Engine… If necessary... Replace the Old Gerotor Oil Pump AND the Oil Pick Up Tube as the Upgrade must be done on BOTH.

(4) If the engine sports the Old Design and you decide NOT to do the Upgrade… Definitely replace the “Blue “0” Ring” as the old one will be worn and flattened out. If you disassemble the Gerotor Gear Set to inspect it for damage… Magic Mark their positions before you remove them from the Pump Body. Disassemble the Oil Bypass Relief Valve and examine it for Piston-Plunger Scuffing… if you see any damage… consider replacing the Pump and the Pick-Up Tube:

Old Style Gerotor Oil Pump:

http://s557.photobucket.com/user/60...EREPAIR/GMGEROTOROILPUMPAUTOPSY?sort=3&page=1

New Style Gerotor Oil Pump:

http://s557.photobucket.com/user/60dgrzbelow0/library/0000TRAILBLAZERENGINEREPAIR/GEROTOROILPUMP?sort=3&page=1

New Style Oil Pick-Up Tube… The Blue “0” Ring is NOT used on the Newer Oil Pump:

http://s557.photobucket.com/user/60...ENGINEREPAIR/GM42LOILPICKUPTUBE?sort=3&page=1

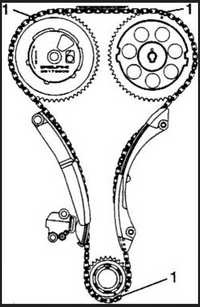

(5) The Cloyes Timing Set was a Brilliant Choice on your part and you can be assured of their Quality of Chain and Tensioner in particular as OEM Best Parts to choose. There are many after-market versions that are just garbage. BOTH. Consider adding a New Rear Crankshaft Seal to the mandatory replacement of the Front Case Seal during this repair and Kill Two Birds with One Stone.

(6) You can make a Catch Basin to slip under the Engine on the Stand using a large cut-down Cardboard Box slipped inside of a Large Lawn Garbage Bag and held in place with a bag of “dust-free” Kitty Litter poured in the bottom. This will help with anything disgusting and all those noxious liquids that wash out of the block will collect with an eye towards safety and the ease of cleaning up. The vaporous mess should be carried out of the building as in quantity… the Berryman’s Chemical stuff in particular can make you feel stomach sick.

(7) If you decide to do any cleaning up of the “Brown-Tan Oil Mung” that covers the lower block interior and portions of the Rotating assembly… Choose stiff, narrow Bathroom Grout Brushes over any Brass or Stainless Steel Brushes as they can shed particles of metal inside of the engine very soon after they get used.

(8) Using Berryman’s C-12 sprayed liberally to dissolve the Mung ...followed by a spray down using Odorless Paint Thinner (Artist’s Paint Thinner) while the Engine is rolled outside of the Building will dissolve most of that mess… and scrubbing the parts and the interior walls of the Aluminum Block while doing so will clean things up nicely. Using a Face Shield and Gloves are recommended when using this stuff.

(9) I’m going to catch some Flak for suggesting this … but I would never assemble any engine without using either Permatex or Royal Purple Engine Assembly Lube on everything that moves except the Pistons, Rings and Cylinder Walls. I would coat all the lobes of both camshafts and liberally douse the Timing Chain and Sprockets as well. Why take any chances whatsoever with the slightest friction?

(10) Before assembling the Gerotor Oil Pump to the Front Timing Cover… either pack the entire interior spaces with White Petroleum Jelly to exclude any Air from causing the pump to cavitate… or mix up a batch of Valvoline Racing Oil with CompCam Engine Break-In Fluid to cover all the insides of the spaces and Gerotor Gears.

(11) After the reassembly and torque down of the fasteners on the Pump Body… You would pour this Gooey Mixture into the inlet side of the pump and hand-turn crank the Gerotor Pump at the center until you can see a steady stream of the fluid coming through.

(12) The proof that the pump is working properly happens after the engine is assembled and installed back inside of the Truck. You would pull the Fuel Pump Relay(s) and Fuses and crank the engine over until the MIL-CEL Low Oil Light goes out on the Dash Panel and re-installing the FP Relays afterwards.

(14) ←

I’m Irrationally Superstitious about Certain Numbers… At around $10-$15.00 a Tube… The AC-Delco RTV for this engine is the only one worth using to guarantee good sealing and security when fastening the GM Atlas LL8 Engine back together. Plan your actions well. Before assembly… Clean all their mating surfaces with a non-residue solvent and work quickly as the component(s) being sealed must be in place and properly torqued down within 10 Minutes of applying a 3MM Bead of this Gray RTV to the Front and Back Covers, Crank-case-Oil-pan and the Front Timing Chain Cover instead of applying the stuff directly onto the Engine Block Flanges.