Was just informed today by my girl, that her 2002 TB 4.2 recently started to crank longer before starting and a couple times she released the key and then cranked again and then would start and seem to falter at idle for a couple seconds. Only happens after been sitting for a longer time, like overnight.

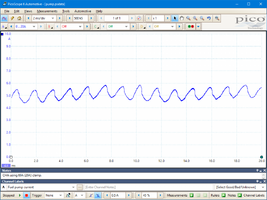

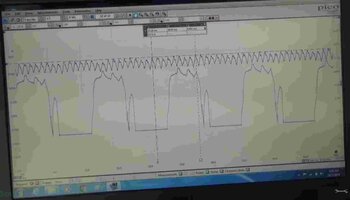

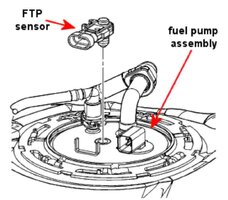

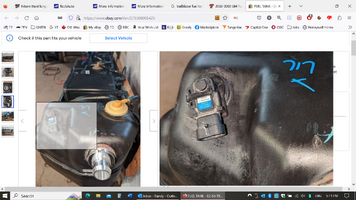

I fear a fuel bleed down after sitting long enough. Gonna test pressure at fuel filter when have better weather and have told her to turn key to KOEO for 10 seconds and then try to start. I drove today with no problems, starting or idle. I fear maybe a pressure regulator but see no leaks there and will check further. Any known problems for the first year TB's, that you guys/girls can share, that might be related or sound like what I am experiencing?

Thanks

I fear a fuel bleed down after sitting long enough. Gonna test pressure at fuel filter when have better weather and have told her to turn key to KOEO for 10 seconds and then try to start. I drove today with no problems, starting or idle. I fear maybe a pressure regulator but see no leaks there and will check further. Any known problems for the first year TB's, that you guys/girls can share, that might be related or sound like what I am experiencing?

Thanks

Last edited: