If you have been curious enough ...and dedicated enough... to separate yourself out and well away from what "Mike, The Disgruntled Mechanic" calls

"The 98%-ers" for the purposes of getting under the skin of

TRUE Automotive Diagnostics entailing the use of Oscilloscopes... There is a steady progression that leads us all from the

LEAST Expensive "O" Scopes with the

LEAST amount of Capabilities and Features... Onward...Towards the "O" Scopes with

GREATER Expense and consummately having the

MOST Number of Improved Capabilities and Features.

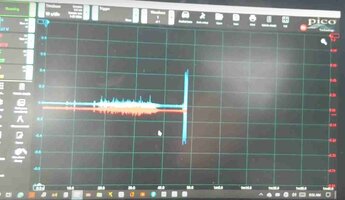

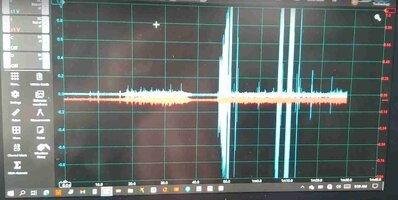

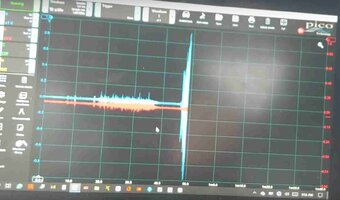

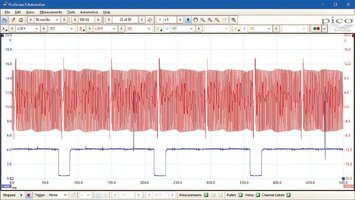

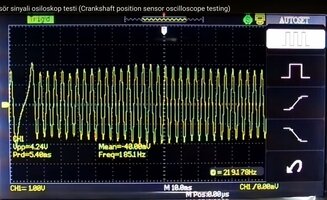

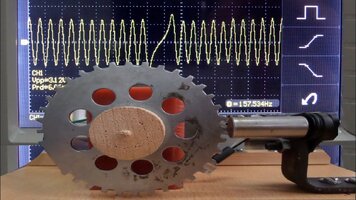

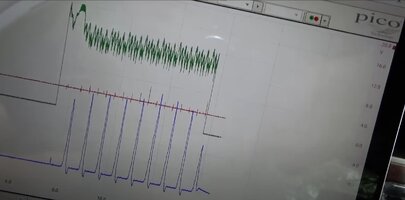

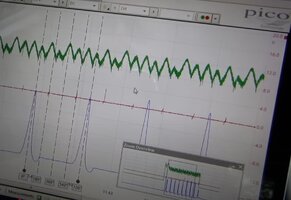

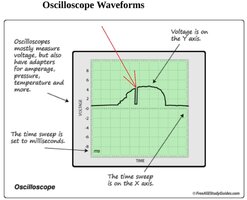

Without making ANY Value Judgements of the Good, Better, Best variances below... These Tools all progress in the direction from having a Basic, 8 Bit "O" Scope Trace with "Jagged" Signal Traces passing on screen along with small sample rates, right up to and beyond the 12 Bit Sensitivity and even well beyond that ...to the point where One Second of Signal Capture can involve isolating BILLIONS OF SAMPLES per second.

And it is THERE that your Automotive Diagnostics can show the Best Level Jumps in Performance by improving the appearance of "SIGNAL FUBAR" well enough to be able to separate out "Subtle Voltage Over Time Variations" that will separate

YOU from the common guesswork of "The Great Unwashed" struggling with

"Well... What The HELL Do I DO Next...?"

It is

THIS issue that allows You to avoid becoming "A Parts Changer". This negative connotation came right along with the advent of EFI and Air Managed Engine and Power Train Systems almost overnight. bringing along the loss of having Mechanical Distributors and the loss of using Two or Four Barrel Carburetors and the loss of using

"Points, Plugs, Timing Lights and Street Cred Tuning Chops set at 30 Degrees BTDC".

These ideas used to be held by us as a "Point of Pride" that most Red-Blooded North American Men owning Chevrolet and GMC Cars and Trucks seized upon as being at the very core of their Automotive Engine Tune & Repair Understanding Prowess.

All of that pretty much became instantaneously

USELESS from the mid-1980s onward... and all the way up to the contemporary issues of having many suffering with the present day problems of keeping Cars and Trucks driving... and NOT driving their Owners INSANE with their maintenance and upkeep.

The sad part about this history is that there were an awful lot of follow-on generations of Young Men and Women who may have had a better introduction to working on their First Cars had Dad (or Mom) been able to have access to the Tools and Skills allowing them to invite the Young Folks outside on any Saturday and lift their Car Hoods and become familiar with how to conduct even the most Basic of Engine Tune Ups if only "The Knowledge and Use of Oscilloscopes" had been common across the landscape of Automotive Acumen.

Most of us around back then might still miss the doing these activities ever since those halcyon and heady days have passed us by when once, we were able to listen to Local, Privately Owned, Non-Corporate AM and FM Radios Stations blasting contemporary music away in the Driveways of Car Enthusiasts

EVERYWHERE assembled en masse...Going Outside to Work On Our Cars.

That pressing paradigm shift brought along the practical impossibility of using "Common Sense Mechanics" and replaced it with a hostage state of confusion, causing us to simply guess at

"What Has Gone Sideways...NOW?". Well...That left us all to the tender mercies of "The Stealerships"...and later on...The Pro Shops serviced with Tools that might as well be made of Solid Gold.

Often, the only responses have been to throwing the contents of Wallets and Purses at these problems, while having to Buy our way out of perpetual mechanical purgatories ...just to be able to keep a decent vehicle ...running decently.

All during these advancing decades came the reality of many people never, ever having a single clue as to what to actually DO or what Tools are required to

REALLY Diagnose Problems and then... Repair them.

That is... Until the advent of Affordable Automotive Oscilloscopes and Higher End Scan Tools have come into vogue.

It is

THIS understanding and the Practice with Oscilloscope Diagnostics that provides us all with the opportunities to Re-claim Our Name to Fame of having and driving all manner of vehicles that we not only understand... but can Diagnose and Repair

OURSELVES with the assistance of this New-Found Knowledge...

and the Professional Grade Tools Available on eBay right now... that won't Bankrupt those interested in REALLY playing in this Game!

What follows in this next Paul "Scanner" Danner YouTube Video is a

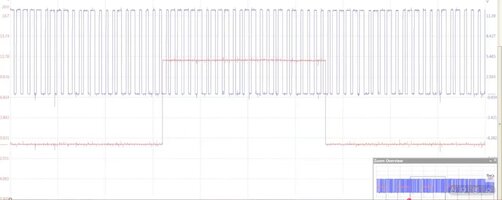

Broad Concept Oscilloscope Training Session from Rosedale College in Pennsylvania wherein he describes How To Diagnose an Engine Misfire on a Toyota 4 Cylinder Engine using Two of the available Four Channel Oscilloscope Features of his Snap-On Verus Diagnostic Scan Tool. Think of

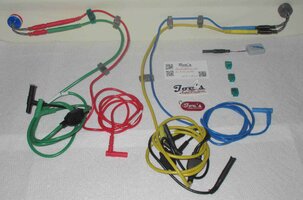

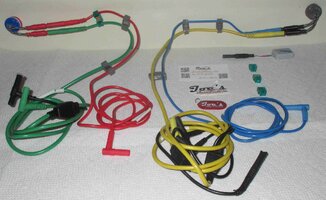

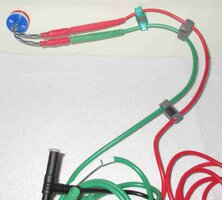

-=The Progression of the Tools Needed To Do This Work=- as follows:

(1) Hantek Model# 1008C (8) Channel "O" Scope

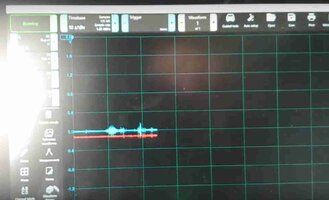

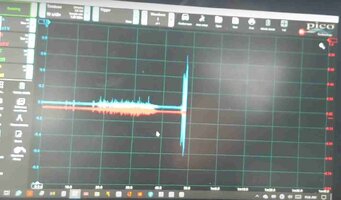

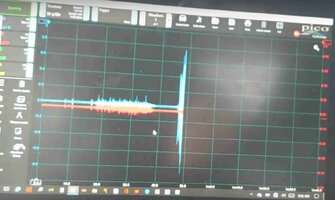

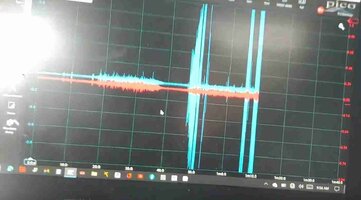

(2) PICO-Scope Model # 2204A (2) Channel "O" Scope

(3

) Autel MAXI-Scope Model# MP408 (4) Channel "O" Scope ****

(4) Snap-On Vantage (2) Channel "O" Scope

(5) Snap-On Vantage Pro (2) Channel "O" Scope

(6) Snap-On Modis (4) Channel "O" Scope

(7) Snap-On Verus (4) Channel "O" Scope

The Basic Approaches to setting up and using Auto Engine Diagnostics shown below apply to

ALL Oscilloscopes...

Every Single One!

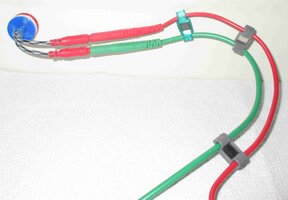

****An Offer on a Brand New Autel MP408 Oscilloscope Kit

The MaxiScope MP408 is a PC based 4-channel automotive oscilloscope. It works in combination with your PC or MaxiSys Tablet, which turns into a powerful diagnostic tool, providing you an insight to the inner workings of a vehicle’s electronic circuits. Featuring the user-friendly UI design...

www.autelmaxisys.com