Hopefully... the fine distribution of the energy of the Rotating Assembly at the Crankshaft Main Bearings will prove out to be sound... even with the obvious need for the replacement of the Con-Rod Bearings. And so... the only engine noise that will be very evident (if at all...) on Cold Start Ups will be

Piston Slap that subsides within a few minutes after the Engine Warms Up

. I hope you will consider this next Technical H/J as being "On Topic"....

These GM OEM Mahle Pistons start out in life with a fairly robust coating of the sides and Piston Skirts with

Graphite Impregnation. Anyone who has ever used the Small Tubes of

Key-Lock Graphite Lubricant can attest to just how

slippery this stuff really is when pressing their Index Fingers and Thumbs together. That is the idea GM and Mahle Engineers came up with to improve the life span of the Pistons inside of the internally, naturally balanced In-line Six Cylinder Atlas LL8 Engines that realistically, can achieve a life span of around 500,000 operational miles under the MOST Ideal Conditions. This is what these Pistons Look Like When Brand NEW compared to the appearance of the images previously posted by @mc.millen he had removed during his GM 4.2L Engine Overhaul:

And that leads us to the

REAL Culprits that sets the stage for these Motors suffering with having Scored Cylinder Walls and Damaged Pistons Skirts so evident in these high Mileage Motors:

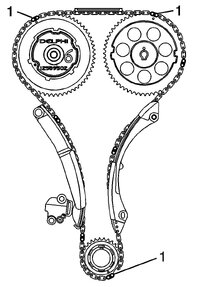

(1)The First Culprit is having Carbon-Seized Compression Rings. Think about it... Ordinarily, the Freely Expanding Compression Rings not only seal in the enormous pressures created during Compression and the Combustion of the F/A Mixture... They also serve to Center the Pistons within the Cylinder Walls during their innumerable travels up and down inside of the Centrifugal - Holt Mold Manufactured Cast Iron 1.5MM Thick Cylinder Sleeves.

But with the Build Up of Carbon deposits and Un-Burned Gas Gum By-Products of incomplete combustion... eventually ...those two top Compression Rings will gradually get squeezed and stuck tightly inside of their respective Piston Grooves... and seize in tightly flush against the sides of each upper Piston.

This condition not only reduces Compression and Power during each Firing at BDC to TDC... but the condition ALSO allows the Pistons to Cant and Move about inside of the Cylinders and begin the wear and tear into BOTH the Power and Return Stoke sides of the cylinder walls of all (6) cylinders. In the end... the

Graphite Coating suffers from too much Wear and Tear... and after that, the much softer Aluminum of the Pistons begins to gradually wear itself down and leave asymmetric scratches and grooves in the side of the Cast Iron Cylinder Walls.

(2) The Second Culprit is having Oil That is TOO Thick to Lubricate In Cold Climes. What is involved here was the lack if GM having the wisdom to Engineer and build in

"Piston Oilers" in the Bottom End to spray Lubricant directly up to the lower Cylinder Walls and Piston Bottoms during Initial Cold Start-Ups in Winters having

VERY DEEP COLD... WELL BELOW THE LINE to add to the problem by limiting Piston to Cylinder Wall Lubrication.

Piston motions in such Dry Conditions can cause them to suffer

Metal To Metal Contact that is EXTREME in the short term but active enough to locally heat up and expand the Pistons wildly at (3) Times the rate of the Cast Iron Cylinders containing them. This condition

REALLY grinds their bodies together when there is No Oil Present at Low Temps to prevent this irreversible contact damage.

In around (5) Months or so,

Arctic Inversions will begin affecting North America and Countless Vehicles will make attempts to be Started with 5W-30 Motor Oil (or even Higher Viscocity Motor Oils) in their Crankcases... instead of having

Mobil1 0W-30 as shown in this Video. By switching to the Lower Viscosity Motor Oil Seasonally...

God Only Knows how much more Life could be added to the GM Atlas Engines:

....

....