Long time no posting, but my truck is fine and has been puttering along daily (in Europe... without a CNG/LPG conversion, with insane gas prices, har har har!)

It's super weird to type this, but it was only during a drive last night that I noticed the front passenger and rear driver's side window switches are dark. The driver's window switch panel, the rear pass window switch and all other switches light up nicely.

I figure this means both affected switches have the light sources dead of age or there's something funky going on in the wiring.

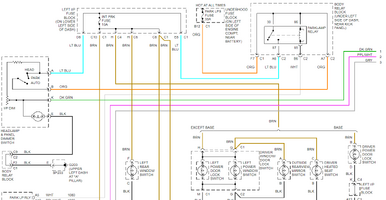

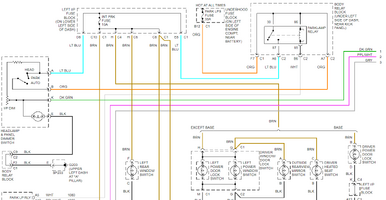

I understand all backlight sources in the window switches (plus other switch panels, like the garage opener) are fed via several brown wires coming from the left I/P fuse block (10 amp fuse, INT PARK) and are triggered the PARKLAMP RELAY (which itself is powered by a 30 amp fuse labelled PARK LPS that lives in the UEC). If the fuses were blown, no backlights on the listed components would come up with interior lights/triggered by the headlamp switch turned on.

I could confidently test the brown power wires feeding the affected window switch lights with a test light, I suppose, to verify they get their 12 volts. Otherwise I would have to take the affected switches apart and replace the light sources.

1. Can the window switches be disassembled safely without irreversibly breaking them?

2. What are the window switch light sources? I understand the backlighting is indirect and works with a single bulb on the switch PCB. Are they T-size wedge-lock bulbs, like the 3 or 3.5-mm white ones? IDK if GM used soldered in LEDs in the window switches.

It's super weird to type this, but it was only during a drive last night that I noticed the front passenger and rear driver's side window switches are dark. The driver's window switch panel, the rear pass window switch and all other switches light up nicely.

I figure this means both affected switches have the light sources dead of age or there's something funky going on in the wiring.

I understand all backlight sources in the window switches (plus other switch panels, like the garage opener) are fed via several brown wires coming from the left I/P fuse block (10 amp fuse, INT PARK) and are triggered the PARKLAMP RELAY (which itself is powered by a 30 amp fuse labelled PARK LPS that lives in the UEC). If the fuses were blown, no backlights on the listed components would come up with interior lights/triggered by the headlamp switch turned on.

I could confidently test the brown power wires feeding the affected window switch lights with a test light, I suppose, to verify they get their 12 volts. Otherwise I would have to take the affected switches apart and replace the light sources.

1. Can the window switches be disassembled safely without irreversibly breaking them?

2. What are the window switch light sources? I understand the backlighting is indirect and works with a single bulb on the switch PCB. Are they T-size wedge-lock bulbs, like the 3 or 3.5-mm white ones? IDK if GM used soldered in LEDs in the window switches.