This Is Very Important...

If anyone intends upon working on ANY LS Engine...whether a Brand New Crate Engine, a Complete Re-Build or as in THIS Case...a Speciously Sourced Engine Swap... You should get serious about

REALLY knowing WTF you are DOING...!

And to that end...in addition to the Tens of Thousands of YouTube Videos available online that will answer MOST of your questions ...almost down to the level of

"Holding Your Hand"...You should be READING MORE about this Engine Platform from your own GM OEM Shop-Service Manual... so you don't keep getting into trouble

.

THIS is the kind of LS Engine Training Book that you WANT to get your hands on:

View attachment 111277

How to Rebuild GM LS-Series Engines (S-A Design) [Chris Werner] on Amazon.com. *FREE* shipping on qualifying offers. How to Rebuild GM LS-Series Engines (S-A Design)

www.amazon.com

Get IT... Read IT... Then ...

READ IT AGAIN!

Moving Back On Topic...

The Freeze Plugs in the LS Engine are well described below by "George from Melling". He will take you through the processes and Kit variations. As ever ...you should be reading directly from your own GM Factory OEM Service Manual for the specifics about your 2001 GM LS LM7 Cast Iron Motor (with Aluminum Engine Heads):

:

This is what can happen if anyone is

too casual with their Swap Engine Prepping and suffers from "

A COMPLETE Failure of Imagination" that usually follows on from using Poor Engine Building or Prep Procedures:

More Technical Insights:

BRASS CORE PLUGS...ONLY Guys!

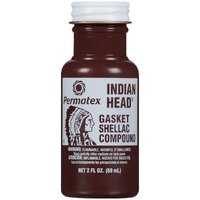

PERMATEX Part # 80017 AVIATION #3D FORM-A-GASKET

...FTW!

View attachment 111302

Do your Homework...Thoroughly... and anticipate that whomever owns ANY of these Swap Motors are not necessarily "Considerate Mechanics" and to

be very suspicious of any internal engine conditions that you should always address well

before you ever just "Drop in a Swap Motor".