Bottom line- Trying to diagnose a crow-hopping condition on a '06 SAAB 9-7x. 195K miles.

I have a 9-7X that appears to be running well EXCEPT for crow-hopping. No OBD2 codes with a scanner and no codes using a Tech2 (makes me feel its purely mechanical that the sensors don't see). I've been replacing parts based on the prior owner's mechanic recommendations- big parts! The vehicle is new to me and I purchased with the known issue, so my history with knowledge of the vehicle is limited. The prior owner had it towed to two mechanics and both diagnosed it as a bad transfer case, but mechanic estimate to replace the transfer case was more than the prior owner could afford (>$2500).

Here's what I have done. I've replaced the transfer case with a "known good" used part. No noticeable change whatsoever. After the transfer case swap made no change, I changed the rear diff fluid and found black goo inside and some small chips of metal. Thinking the rear differential is toast, I replaced the read diff (G86 limited slip) with a "known good" used part (with only 30K miles!). Again, no change whatsoever to vehicle performance. In both instances I replaced the fluid with appropriate GM fluid.

I understand the risks with replacing with used parts. Statistically, I should have seen some sort of change if the parts I installed are better -or worse.

I then replaced the fluid in the front diff. It was significantly low and the old fluid had very fine metal shavings- hard to tell if significant enough to call it bad, but more than I expected. Of course, hindsight is 20/20 and I should have checked/changed this fluid level earlier, but the prior owner swore it was maintained perfectly.

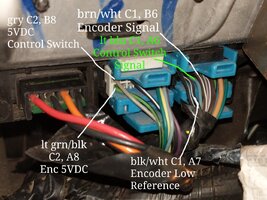

I am hoping for a way to isolate the problem. Reading many many posts I have come up with several ideas to help troubleshoot. One idea is to pull the encoder motor to see of the front drive is responsible for the problems. Alternatively, can I remove the front driveshaft and test it as a 2wd? What is the likelihood of the CV axles contributing to the crow-hopping by binding? (grasping at straws here). What is the impact of the encoder motor removed and/or front drive shaft?

Thanks in advance for an sage advice.

Joe

I have a 9-7X that appears to be running well EXCEPT for crow-hopping. No OBD2 codes with a scanner and no codes using a Tech2 (makes me feel its purely mechanical that the sensors don't see). I've been replacing parts based on the prior owner's mechanic recommendations- big parts! The vehicle is new to me and I purchased with the known issue, so my history with knowledge of the vehicle is limited. The prior owner had it towed to two mechanics and both diagnosed it as a bad transfer case, but mechanic estimate to replace the transfer case was more than the prior owner could afford (>$2500).

Here's what I have done. I've replaced the transfer case with a "known good" used part. No noticeable change whatsoever. After the transfer case swap made no change, I changed the rear diff fluid and found black goo inside and some small chips of metal. Thinking the rear differential is toast, I replaced the read diff (G86 limited slip) with a "known good" used part (with only 30K miles!). Again, no change whatsoever to vehicle performance. In both instances I replaced the fluid with appropriate GM fluid.

I understand the risks with replacing with used parts. Statistically, I should have seen some sort of change if the parts I installed are better -or worse.

I then replaced the fluid in the front diff. It was significantly low and the old fluid had very fine metal shavings- hard to tell if significant enough to call it bad, but more than I expected. Of course, hindsight is 20/20 and I should have checked/changed this fluid level earlier, but the prior owner swore it was maintained perfectly.

I am hoping for a way to isolate the problem. Reading many many posts I have come up with several ideas to help troubleshoot. One idea is to pull the encoder motor to see of the front drive is responsible for the problems. Alternatively, can I remove the front driveshaft and test it as a 2wd? What is the likelihood of the CV axles contributing to the crow-hopping by binding? (grasping at straws here). What is the impact of the encoder motor removed and/or front drive shaft?

Thanks in advance for an sage advice.

Joe