You don't mention the Engine Mileage... but another source for Low RPM, Asymmetric Vibration (Rough Running Engine) on High Mileage Motors can come from

Worn Main Bearings and the Thrust Bearings situated at a Right Angle to the Axis of Rotation involving the Two Babbitt Thrust Plates slipped alongside the #5 Mains Bearing Buttress.

In short... if the Bearings are worn out... as mentioned by

@Mooseman ... replacing the Harmonic Balancer as a Low Failure, Massive Bi-Component System separated by an Elasto-Meric Binder

would not necessarily solve this problem. It

IS possible to measure the wear of the Thrust Bearings by attempting to take a longitudinal movement measurement with a Dial Bore Gauge reading the Flat Outer Surface of the Harmonic Balancer... Fore and Aft ... for Excessive End Play and following the comparison of Nominal OEM Factory Specs versus any Excessive End Play Measurement suggesting an impending Engine Failure:

THIS Information should prove useful... even though

THIS relates to 2005-2006 Engines, but take note of the

Highlighted Specifications below for reference to your situation.:

Subject: DTC P0014, P0017, and/or Belt Noise - Inspect Actuator Solenoid and Crank End Play - keywords bearing cam chirp damaged debris internal light metal P0106 Phaser replacement run SES squeak thrust #PIP3693B - (04/04/2006)

Models:2005-2006 Buick Rainier 2005-2006 Chevrolet TrailBlazer 2005-2006 GMC Envoy 2005-2006 Saab 9-7x with 4.2L Engine (VIN S - RPO LL8)

The following diagnosis might be helpful if the vehicle exhibits the symptom(s) described in this PI.

Condition/Concern:

On rare occasions, a

rough idle may be encountered with a P0014 and/or P0017 DTC. Due to the rough idle, a P0106 DTC may be stored too. This concern may be due to debris in the camshaft actuator system, which may be caused by a missing camshaft actuator solenoid screen or a worn crankshaft thrust bearing. Typically, this is the result of a camshaft actuator solenoid concern. If this is due to a worn crankshaft thrust bearing, some customers may also comment on a drive belt noise.

Recommendation/Instructions:

If this concern is encountered, follow the SI diagnostics and repair as necessary. If the SI diagnostics do not isolate the cause of this concern, ensure that camshaft actuator solenoid screens 1, 2, and 3 are in place as shown below:

(1)Screen for Advance Pressure to Camshaft Actuator( 2) Screen for Pressurized Oil from Oil Pump(3)Screen for ****** Pressure to Camshaft Actuator If any of these screens are missing, replace the camshaft actuator solenoid, change the engine oil and filter, and evaluate the concern.

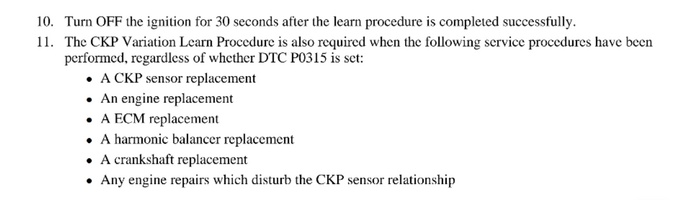

If all these screens are present, measure the crankshaft end play to determine if it is within the specification of 0.0044" - 0.0153" (0.112 - 0.388 mm). Typically, if excessive crankshaft end play is causing this concern, it will be obviously out of specification by .050" or more. If crankshaft end play is within specification, replace the camshaft actuator solenoid.

If the crankshaft end play is obviously out of specification, inspect the engine block for damage due to contact with the crankshaft. If engine block damage is present, contact the PQC (Product Quality Center) at 1-866-654-7654 for engine replacement authorization.

If there is no engine block damage present, disassemble the engine and inspect the following components for damage due to thrust bearing debris in the engine oil: all bearings, all journals, all valve-train components, all timing components, and the crankshaft

Then, estimate what it will cost to replace the oil pump, camshaft actuator solenoid, all damaged parts, and to completely disassemble the engine to thoroughly clean all of the cylinder head and engine block oil galleys with oil galley brushes and soapy water.

After the repair estimate is complete, estimate what it would cost to replace the engine and contact the PQC to review these estimates as outlined in 02-07-30-029F.

Important: On 2006 models with excessive crankshaft end play, please submit a field product report by following 02-00-89-002D.

Please follow this diagnostic or repair process thoroughly and complete each step. If the condition exhibited is resolved without completing every step, the remaining steps do not need to be performed.