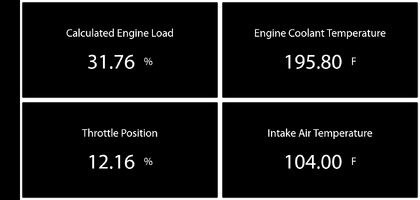

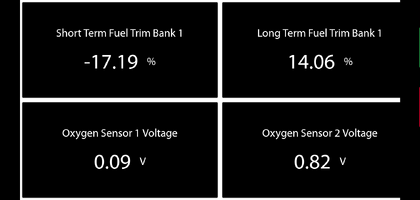

So I have an 05 Chevy Trailblazer 189 thousand miles on it I recently replaced the spark plugs with ACDelco iridium I change the coils and the fuel injectors. For the new exhaust manifold in my summer and a new valve cover gasket and intake gasket 2 months ago ever since then I have a p303 code that will not go away all this started with the p300 code. So I took some pictures of some real time data I was hoping that maybe you guys could give me some pointers possibly any and all help will be appreciated thanks.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

At a total loss...

- Thread starter Johnnyjh84

- Start date

Blckshdw

Moderator

A Dirty Air Filter and a Dirty Mass Air Flow Sensor can cause a P0303-P0300 condition as well as having any Vacuum Leaks around the Intake Manifold Gaskets (Re-Tighten to 87 Inch Pounds ONLY) or having Bad Spark Plugs - Coils on Plugs.

Some small amount of Debris-Detritus can also be coating the Small Resistors hidden inside of the MAF that should ONLY be cleaned VERY Gently using a Soft Brush and with Plenty of Spray Shots of the CRC MAF Solvent ONLY. Replace the Air Filter if it is Dirty.

If the Exhaust Manifold Bolts are BRAND NEW from the time that you replaced the Exhaust Manifold last summer, the Bolts may have have since subsided or relaxed. Unmetered Air can be entering the Exhaust Stream around a loose Exhaust MLS gasket and confuse the O2 Readings.

This can prompt adding in More Fuel unnecessarily. If your STFT levels are in the High Negatives... this would indicate that in response to any errant signals from the Upstream O2 Sensor... the PCM will is trying to take Fuel away. With that occurring, the LTFT Levels will gradually rise as well.

Try using a Small Torque Wrench and apply NO MORE than 15 Foot Pounds of Force as you go around the Exhaust Flange and SLOWLY re-tighten those Fasteners. BE Careful Here... The idea is to just Snug Them Right Back Up...NOT tighten any enough to have them Snap Off.

Some small amount of Debris-Detritus can also be coating the Small Resistors hidden inside of the MAF that should ONLY be cleaned VERY Gently using a Soft Brush and with Plenty of Spray Shots of the CRC MAF Solvent ONLY. Replace the Air Filter if it is Dirty.

If the Exhaust Manifold Bolts are BRAND NEW from the time that you replaced the Exhaust Manifold last summer, the Bolts may have have since subsided or relaxed. Unmetered Air can be entering the Exhaust Stream around a loose Exhaust MLS gasket and confuse the O2 Readings.

This can prompt adding in More Fuel unnecessarily. If your STFT levels are in the High Negatives... this would indicate that in response to any errant signals from the Upstream O2 Sensor... the PCM will is trying to take Fuel away. With that occurring, the LTFT Levels will gradually rise as well.

Try using a Small Torque Wrench and apply NO MORE than 15 Foot Pounds of Force as you go around the Exhaust Flange and SLOWLY re-tighten those Fasteners. BE Careful Here... The idea is to just Snug Them Right Back Up...NOT tighten any enough to have them Snap Off.

Last edited:

Blckshdw

Moderator

Also, if you swap coils/plugs with a different cylinder, does the code change?

Mooseman

Moderator

And while you're there, a complete compression test would be useful.

Do you have the ability to watch cylinder misfires as they happen? Is it a continuous misfire or random? At idle, driving? I had chased a random misfire at idle on my 07. If you want to read a bit, you can also follow the same troubleshooting steps I took:

gmtnation.com

gmtnation.com

Do you have the ability to watch cylinder misfires as they happen? Is it a continuous misfire or random? At idle, driving? I had chased a random misfire at idle on my 07. If you want to read a bit, you can also follow the same troubleshooting steps I took:

Very Slight Miss at Idle

Yesterday on the TB, at 117k km, saw the CEL come on and code came up for P0304. Fired up Torque and it was missing on cylinder #4 but only at idle or stopped at a light. It's not a big miss since I can't feel it at all and it's just a couple of misses per refresh cycle. While driving...

Seems to only be on idle. Runs great down the road.. no ability to watch misfires happening did the compression test and I think I had a post about it once a week ago.. ilI have to look into your purse thoughAnd while you're there, a complete compression test would be useful.

Do you have the ability to watch cylinder misfires as they happen? Is it a continuous misfire or random? At idle, driving? I had chased a random misfire at idle on my 07. If you want to read a bit, you can also follow the same troubleshooting steps I took:

[URL I'munfurl="true"]https://gmtnation.com/forums/threads/very-slight-miss-at-idle.19196/[/URL]

Wiring looks ok and is getting power.Have you inspected/tested the wiring to that coil?

Stays the same..Also, if you swap coils/plugs with a different cylinder, does the code change?

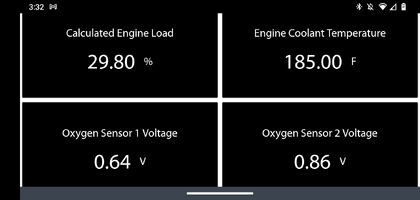

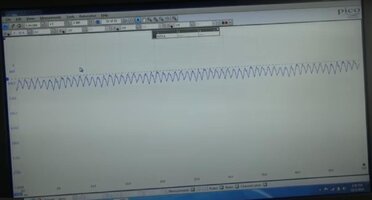

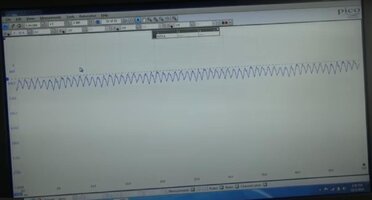

are all those images posted for "idle / warm"? Those trims seem awfully out of "normal". What are you capturing those data with? Even though you have seen a "p0303" set doesn't mean much in terms of chasing a misfire... because that just means the "misfiring" happened enough on the one cylinder to cross the "bogey line" but other cylinders could also be "less misfiring". You need to get an interface that allows you to look at "all cylinders" data to get a better idea of the scope / width of the problem... ie one cylinder only or multiple cylinders (with some misfiring). A cheap bluetooth and android torque app is all you need.

does your truck have a MAF (not sure of what year they started having them... 2005 ... 2006)? If it does, try disconnecting it and see if it will start... check the trims during that test. IF it does not start, then look towards the MAP as that sensor plays a major role during idle / start.

Of course, this is based on the possibility that the misfiring is across more than one cylinder.

does your truck have a MAF (not sure of what year they started having them... 2005 ... 2006)? If it does, try disconnecting it and see if it will start... check the trims during that test. IF it does not start, then look towards the MAP as that sensor plays a major role during idle / start.

Of course, this is based on the possibility that the misfiring is across more than one cylinder.

Last edited:

No MAFare all those images posted for "idle / warm"? Those trims seem awfully out of "normal". What are you capturing those data with? Even though you have seen a "p0303" set doesn't mean much in terms of chasing a misfire... because that just means the "misfiring" happened enough on the one cylinder to cross the "bogey line" but other cylinders could also be "less misfiring". You need to get an interface that allows you to look at "all cylinders" data to get a better idea of the scope / width of the problem... ie one cylinder only or multiple cylinders (with some misfiring). A cheap bluetooth and android torque app is all you need.

does your truck have a MAF (not sure of what year they started having them... 2005 ... 2006)? If it does, try disconnecting it and see if it will start... check the trims during that test. IF it does not start, then look towards the MAP as that sensor plays a major role during idle / start.

Of course, this is based on the possibility that the misfiring is across more than one cylinder.

So I was going back through everything I pulled intake to check the gasket make sure everything's okay there. Everything seemed to be in order now trying to put the intake back on the bolts in the middle,well the fourth set from the front will not start at all what's going on with that please help me...

Another thing to consider is the condition of the Fuel Pump:

Changes in Fuel Pressure on a Failing Fuel Pump can drop enough at random to affect the EFI Spray Levels randomly up and down the I-6 Cylinder Bank. Also, if the #3 Cylinder has a "Weak Sister" among all of the EFIs... it might react poorly more so than the other five to Diminished Fuel Pressure.

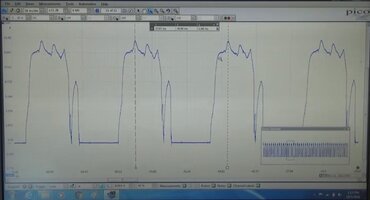

Unless your vehicle sports an External Fuel Test Port making it an easy job to Test the Running Fuel Pump Pressure via attaching a Schrader fitted Hose and an Analog Fuel Pressure Gauge. the alternative (Definitive) way to test the Fuel Pump is by using an Inexpensive Hantek 1008C Oscilloscope, a Low Amperage Clamp, a 20:1 Attenuator and a "Fuse Buddy" Variable Fusing (0-30 Amps) Current Loop.The Hantek Software Suite needs to be installed either on a Windows Laptop or Tablet first and then have the Hantek Oscilloscope attached to it via a USB Cable.

All of this Gear is available on Amazon either as Complete Hantek Kits or as separate items:

After temporarily replacing the Fuel Pump Fuse with the "Fuse Buddy" Current Loop fitted with that same Fuel Pump Fuse, Clamp the Low Amp Clamp around that Loop and attach the Low Amp Clamp Wire with its BNC Connector to the Channel #1 Position on the back of the Hantek Scope with a 20:1 Attenuator installed in between. Then open the Hantek Software Suite installed on your Laptop and Start the SUV.

The Hantek Oscilloscope will display the converted 'Voltage over Time' behavior of the Fuel Pump as it runs on the Laptop screen via a Graph representing the Voltage as Amplitude on the Vertical Axis-Scale and the Frequency of Action (in Time Segments) on the Horizontal Axis in Milli-Seconds.

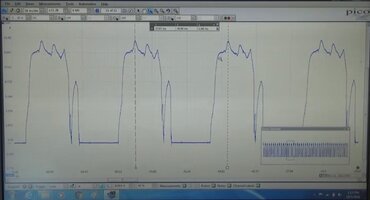

Of course these can be adjusted to fit on the Laptop Screen in both aspects. If the Fuel Pump Wave form is BAD, it will show that the Commutators of the Electric Fuel Pump Motor inside the Fuel Tank as a Broken Up Wave Form with HUGE Gaps in the Up and Down Fuel Pump Electric Motor Commutator Oscillations that will look something like THIS:

However, if the Fuel Pump Wave Form shows up on screen looking like THIS one...then the Fuel Pump is Functioning Nominally. Fuel Pumps can have 8,10 or even 12 of these jagged Peaks and Valleys... and the jagged, symmetrical signal simply repeats itself moving from Right to Left across the Grid on the Laptop Screen. THIS would be the desired outcome of this Fuel Pump Test and being able to precisely know the real condition of the running Fuel Pump:

There are numerous YouTube Videos demonstrating How to Use a Hantek Automotive Oscilloscope". The investment of the time needed to get familiar with this Tool Kit and reasonable Cost involved will offset having to Remove the Fuel Tank if the condition of the Fuel Pump is in Question and replace it on a mere Guess that it is the problem. There is nothing more satisfying than NOT having to go through the agonies of replacing any GM Fuel Pump if it is not necessary.

Changes in Fuel Pressure on a Failing Fuel Pump can drop enough at random to affect the EFI Spray Levels randomly up and down the I-6 Cylinder Bank. Also, if the #3 Cylinder has a "Weak Sister" among all of the EFIs... it might react poorly more so than the other five to Diminished Fuel Pressure.

Unless your vehicle sports an External Fuel Test Port making it an easy job to Test the Running Fuel Pump Pressure via attaching a Schrader fitted Hose and an Analog Fuel Pressure Gauge. the alternative (Definitive) way to test the Fuel Pump is by using an Inexpensive Hantek 1008C Oscilloscope, a Low Amperage Clamp, a 20:1 Attenuator and a "Fuse Buddy" Variable Fusing (0-30 Amps) Current Loop.The Hantek Software Suite needs to be installed either on a Windows Laptop or Tablet first and then have the Hantek Oscilloscope attached to it via a USB Cable.

All of this Gear is available on Amazon either as Complete Hantek Kits or as separate items:

After temporarily replacing the Fuel Pump Fuse with the "Fuse Buddy" Current Loop fitted with that same Fuel Pump Fuse, Clamp the Low Amp Clamp around that Loop and attach the Low Amp Clamp Wire with its BNC Connector to the Channel #1 Position on the back of the Hantek Scope with a 20:1 Attenuator installed in between. Then open the Hantek Software Suite installed on your Laptop and Start the SUV.

The Hantek Oscilloscope will display the converted 'Voltage over Time' behavior of the Fuel Pump as it runs on the Laptop screen via a Graph representing the Voltage as Amplitude on the Vertical Axis-Scale and the Frequency of Action (in Time Segments) on the Horizontal Axis in Milli-Seconds.

Of course these can be adjusted to fit on the Laptop Screen in both aspects. If the Fuel Pump Wave form is BAD, it will show that the Commutators of the Electric Fuel Pump Motor inside the Fuel Tank as a Broken Up Wave Form with HUGE Gaps in the Up and Down Fuel Pump Electric Motor Commutator Oscillations that will look something like THIS:

However, if the Fuel Pump Wave Form shows up on screen looking like THIS one...then the Fuel Pump is Functioning Nominally. Fuel Pumps can have 8,10 or even 12 of these jagged Peaks and Valleys... and the jagged, symmetrical signal simply repeats itself moving from Right to Left across the Grid on the Laptop Screen. THIS would be the desired outcome of this Fuel Pump Test and being able to precisely know the real condition of the running Fuel Pump:

There are numerous YouTube Videos demonstrating How to Use a Hantek Automotive Oscilloscope". The investment of the time needed to get familiar with this Tool Kit and reasonable Cost involved will offset having to Remove the Fuel Tank if the condition of the Fuel Pump is in Question and replace it on a mere Guess that it is the problem. There is nothing more satisfying than NOT having to go through the agonies of replacing any GM Fuel Pump if it is not necessary.

Last edited:

Cheap bluetooth what ?? I do have thie fixed ob2 reader that's blue tooth and a plug in actronare all those images posted for "idle / warm"? Those trims seem awfully out of "normal". What are you capturing those data with? Even though you have seen a "p0303" set doesn't mean much in terms of chasing a misfire... because that just means the "misfiring" happened enough on the one cylinder to cross the "bogey line" but other cylinders could also be "less misfiring". You need to get an interface that allows you to look at "all cylinders" data to get a better idea of the scope / width of the problem... ie one cylinder only or multiple cylinders (with some misfiring). A cheap bluetooth and android torque app is all you need.

does your truck have a MAF (not sure of what year they started having them... 2005 ... 2006)? If it does, try disconnecting it and see if it will start... check the trims during that test. IF it does not start, then look towards the MAP as that sensor plays a major role during idle / start.

Of course, this is based on the possibility that the misfiring is across more than one cylinder.

Is it possible to strip it out???When I reinstall that intake, I start with a single front bolt, just get it started, then lower middle bolt.

Be aware of the angle of the manifold, takes a little bit of finesse but it should start, just don't force it.

gmcman

Member

- Dec 12, 2011

- 4,656

Is it possible to strip it out???

I suppose but you would have likely felt it cross-threading.

Those bolts are somewhat held in the intake to aid in R&R. Are you sure you have fully pushed them in so they make contact with the head? May give a false sense of grabbing the threads on the head, when actualy they are gripping the intake.

You could easily back them out far enough when removing the intake to do this.

Just go easy, they only require 89 INCH POUNDS.

You may want to source a new bolt if the threads looked messed up. Also clean the threads with a thread chaser, don't use a tap unless absolutely necessary.

Dadwagon

Member

Why is the idle so low? Should be just above 600rpm normally at idle. Did the throttle body get relearned?

if you have an obd interface (elm327 / bluetooth based) then an android app called torque will give you access to all the data about misfires that you need.Cheap bluetooth what ?? I do have thie fixed ob2 reader that's blue tooth and a plug in actron

Is it possible to strip it out???

I think you may have accidentally put your finger on the possible source of the P0303 problem. The (10) 'Trapped' Fasteners staggered along the Intake Manifold Plastic Flange are designed with very small Metric Threaded ends that are susceptible to easy breakage. M6 X 1.00 Thread Count seems correct. GM and GMPartsDirectdotcom do NOT carry any replacements, so either a salvage yard or eBay may be your only recourse to obtain the correct replacement consistent with the other OEM 'Trapped' Bolts.

The OTHER possibility would be Stripping Out the Threaded IM Bolt Hole inside the Engine Head. If that proves to be the issue, Do NOT Despair. Check out Post # 9-11 in THIS Thread where I explain how to use a TIME-SERT Repair Kit that employs a unique " Sert STI" Screw Thread Insert Steel Cylinder to permanently fix this problem. Note that the COP Bolt Holes and the Intake Manifold "Trapped" Bolt Holes share the SAME Dimensions of M6 X 1.00:

gmtnation.com

gmtnation.com

The Sealing force demanded of them is a Maximum of 89 Inch Pounds because they are only supposed to compress the Plastic IM Shell inwards just enough to*Squash* down on the hopefully Brand New Rubber "O" Ring Style Gaskets and then STOP. These Three "Plump" Rubber Gaskets are roughly shaped like Figure Eights and Do NOT Seal beyond the spaces just around the Three Paired Intake Ports on the smooth surfaces of the Engine Head.

If the the One located in that "Hidden" space snapped off inside the Engine Head... then the Perfect Seal adjacent the #3 Cylinder Intake Port might be compromised and occasionally allow unregulated Ambient Air to leak in just ahead of the Intake Manifold Runner, adding in Un-Metered Air. This condition can come and go depending upon the Engine Head expanding and contracting with changes in Engine and Environmental temperatures and NOT give a consistent P0303 Misfire Code in response.

The only way to confirm this would be to examine and compare all of the remaining Fasteners on the perimeter of the IM and see if the one mentioned appears to be Foreshortened. If the lower end of the Bolt HAS snapped off inside the head, try using a Good Mechanics Pick FIRST to coax it out CCW and avoid having to use Tiny Drills and a Small EZ-Out in those very cramped quarters to get at it. Most of the time, it will come out without much difficulty. A Very Bright Flashlight and some patience works well with that Pick, too. While working, Plug Up the Intake Ports with Scott "Blue" Shop Towels to prevent dropping the Bolt Remnant inside of the nearby Cylinders.

The OTHER possibility would be Stripping Out the Threaded IM Bolt Hole inside the Engine Head. If that proves to be the issue, Do NOT Despair. Check out Post # 9-11 in THIS Thread where I explain how to use a TIME-SERT Repair Kit that employs a unique " Sert STI" Screw Thread Insert Steel Cylinder to permanently fix this problem. Note that the COP Bolt Holes and the Intake Manifold "Trapped" Bolt Holes share the SAME Dimensions of M6 X 1.00:

NEED HELP - Ignition Coils

I was cleaning my engine bay and I notice that 2 coils were loose. I tried to snug the bolts down but they're both stripped. How can I fix this problem?

The Sealing force demanded of them is a Maximum of 89 Inch Pounds because they are only supposed to compress the Plastic IM Shell inwards just enough to*Squash* down on the hopefully Brand New Rubber "O" Ring Style Gaskets and then STOP. These Three "Plump" Rubber Gaskets are roughly shaped like Figure Eights and Do NOT Seal beyond the spaces just around the Three Paired Intake Ports on the smooth surfaces of the Engine Head.

If the the One located in that "Hidden" space snapped off inside the Engine Head... then the Perfect Seal adjacent the #3 Cylinder Intake Port might be compromised and occasionally allow unregulated Ambient Air to leak in just ahead of the Intake Manifold Runner, adding in Un-Metered Air. This condition can come and go depending upon the Engine Head expanding and contracting with changes in Engine and Environmental temperatures and NOT give a consistent P0303 Misfire Code in response.

The only way to confirm this would be to examine and compare all of the remaining Fasteners on the perimeter of the IM and see if the one mentioned appears to be Foreshortened. If the lower end of the Bolt HAS snapped off inside the head, try using a Good Mechanics Pick FIRST to coax it out CCW and avoid having to use Tiny Drills and a Small EZ-Out in those very cramped quarters to get at it. Most of the time, it will come out without much difficulty. A Very Bright Flashlight and some patience works well with that Pick, too. While working, Plug Up the Intake Ports with Scott "Blue" Shop Towels to prevent dropping the Bolt Remnant inside of the nearby Cylinders.

Last edited:

gmcman

Member

- Dec 12, 2011

- 4,656

Why is the idle so low? Should be just above 600rpm normally at idle. Did the throttle body get relearned?

I should have been more clear on the idle, when talking about raising the idle slightly that's to increase pump pressure.

I would like to re quote this, again, and state that I apologize I was thinking of a transmission thread.

Ok will give it a tryI suppose but you would have likely felt it cross-threading.

Those bolts are somewhat held in the intake to aid in R&R. Are you sure you have fully pushed them in so they make contact with the head? May give a false sense of grabbing the threads on the head, when actualy they are gripping the intake.

You could easily back them out far enough when removing the intake to do this.

Just go easy, they only require 89 INCH POUNDS.

You may want to source a new bolt if the threads looked messed up. Also clean the threads with a thread chaser, don't use a tap unless absolutely necessary.

Ok sweet is the elms/327 a good one to get??if you have an obd interface (elm327 / bluetooth based) then an android app called torque will give you access to all the data about misfires that you need.

Goo

well I believe I may have fouty6I suppose but you would have likely felt it cross-threading.

Those bolts are somewhat held in the intake to aid in R&R. Are you sure you have fully pushed them in so they make contact with the head? May give a false sense of grabbing the threads on the head, when actualy they are gripping the intake.

You could easily back them out far enough when removing the intake to do this.

Just go easy, they only require 89 INCH POUNDS.

You may want to source a new bolt if the threads looked messed up. Also clean the threads with a thread chaser, don't use a tap unless absolutely necessary.

Well the reason I couldn't feel the bolt stI suppose but you would have likely felt it cross-threading.

Those bolts are somewhat held in the intake to aid in R&R. Are you sure you have fully pushed them in so they make contact with the head? May give a false sense of grabbing the threads on the head, when actualy they are gripping the intake.

You could easily back them out far enough when removing the intake to do this.

Just go easy, they only require 89 INCH POUNDS.

You may want to source a new bolt if the threads looked messed up. Also clean the threads with a thread chaser, don't use a tap unless absolutely necessary.

Okay turns out those two bolts weren't stripped the reason they were just spinning is because they broke off in the head. I was able to move one of the boats from head using the weld method but there's really nothing to grab a hold up on the other one what do I do? I know,I know stop breaking bolts a know the torque. This is all new to me gentlemen so please bear with me. So hear I stand stuck with one bolt in manifold, what's next? Oh yes I also thought it was weird that the carb cleaner didn't show up a vac leak when I sprayed it in that area.. well we're heading to the right direction guys thanks again I appreciate it..I suppose but you would have likely felt it cross-threading.

Those bolts are somewhat held in the intake to aid in R&R. Are you sure you have fully pushed them in so they make contact with the head? May give a false sense of grabbing the threads on the head, when actualy they are gripping the intake.

You could easily back them out far enough when removing the intake to do this.

Just go easy, they only require 89 INCH POUNDS.

You may want to source a new bolt if the threads looked messed up. Also clean the threads with a thread chaser, don't use a tap unless absolutely necessary.

gmcman

Member

- Dec 12, 2011

- 4,656

At least the broken bolt is in a workable area and not in the rear of the head.

You might be able to source a diesel mechanic with a service truck and it might cost you a little bit but he might be able to come out and weld a nut on to the broken part and get it right out.

You might be able to source a diesel mechanic with a service truck and it might cost you a little bit but he might be able to come out and weld a nut on to the broken part and get it right out.

That is how I got the first one out and I can't seem to get this other I guess I can look for someone like that.At least the broken bolt is in a workable area and not in the rear of the head.

You might be able to source a diesel mechanic with a service truck and it might cost you a little bit but he might be able to come out and weld a nut on to the broken part and get it right out.

You could also try using a Small Left-Hand Drill Bit in that space... again with VERY Gentle Drill Pressure and VERY Low Drilling Speed. The attached image is just an example of the Left Hand Titanium-Nitride Drill Bit Sets that Amazon, AutoZone, NAPA and perhaps Home Depot carry as well. The Tiny Drill Bits will break apart if they are not directed in at a Right Angle to the Aluminum Engine Head.

Any lateral motions of the Drill that mis-align them will snap them right off. Try guiding in a slender Center Punch capable of reaching the upper part of the broken stud first and lightly Dimple the middle of that bolt shank. Just Remember... Using Low Speed and Light Pressure is half the battle here. Sometimes... the mere action of the Counter-Clockwise Left Hand turning Drill Bit Teeth is often just enough to Bite into and guide that broken bolt portion right on out of the Aluminum Engine Head. Good Luck...

Any lateral motions of the Drill that mis-align them will snap them right off. Try guiding in a slender Center Punch capable of reaching the upper part of the broken stud first and lightly Dimple the middle of that bolt shank. Just Remember... Using Low Speed and Light Pressure is half the battle here. Sometimes... the mere action of the Counter-Clockwise Left Hand turning Drill Bit Teeth is often just enough to Bite into and guide that broken bolt portion right on out of the Aluminum Engine Head. Good Luck...

Last edited:

I still have a Miss on 3 only at idle.. I think I've checked everything plugs are fine coils are good compressions reading 180 across the board can't figure this out. What should my timing be reading on my obd2?

Mooseman

Moderator

Not sure why you want to know the timing since it's controlled by the PCM and non-adjustable. I'd be looking at the live data for misfires on all cylinders.

However, looking at your fuel trims in your first post, they're a little out of whack. The STFT is high negative (taking fuel away) but LTFT is adding fuel. Has that changed?

However, looking at your fuel trims in your first post, they're a little out of whack. The STFT is high negative (taking fuel away) but LTFT is adding fuel. Has that changed?

I repaired the broken bolts and put the manifold all back together. There doesn't seem to be any leaks that I can hear nor find with propane. Redone compression test and it was about 180ish all across the board. I got my new elm/327 in the mail yesterday so I'm trying to put together a few things right now I'll take some pics and post them up and then hopefully you guys can give me some information. I already did and misfire count graph and in 2 days I logged over 40,000 misses on cylinder 3 and so under three alone no this is anywhere else. All right thanks for everything guys I really appreciate it be back in a few with some pics.

It doesn't, that was the first thing I did then plugs then injectors and finally compression. But that damn miss on 3 will not go away and it only happens at idle. Anyways my girlfriend and I both have trailblazers hers is a 2006 lt my is a 2005 ls. So I decided to check her real time data and compare it to mine to see if that got me anywhere the only problem is that's the year they changed the tb it now has a MAF sensor and different coils plus more 🐴 power. But I did notice that my advance timing goes alot higher than hers and a erratically topping off at like 26-27 at idle.. Then again I have a tune from pcmofnc ughhhhh.

Asked about the timing because I have a tune from pcmofnc and wonderd if that could be causing it. Yes fuel trims have changed but I'll have to post them in the morning because I can't remember exactly what they are...Not sure why you want to know the timing since it's controlled by the PCM and non-adjustable. I'd be looking at the live data for misfires on all cylinders.

However, looking at your fuel trims in your first post, they're a little out of whack. The STFT is high negative (taking fuel away) but LTFT is adding fuel. Has that changed?

gmcman

Member

- Dec 12, 2011

- 4,656

This is a valid point. Was it a screenshot during fluctuation? Can it hold 600 RPM when warm, +- 5-ish RPM?Why is the idle so low? Should be just above 600rpm normally at idle. Did the throttle body get relearned?

What is your alternator output voltage at idle? Use a DMM, not the dash gauge.

I would want to make sure the valves are seating. Using a vacuum gauge, you can connect to the evap port on the TB, or the port on the intake resonator, I would use the TB.

If the needle is steady, meaning a very slow, gentle swing, almost imperceivable, when the TB is controlling the idle is good. If the needle bounces back and forth rapidly, even a little bit, that would indicate an intake valve not fully seating.

Take an index card, or envelope, hold against the exhaust flow of the tailpipe, the exhaust should keep it pushed away. If it slaps back to the tailpipe, then you might have an exhaust valve fully seating.

I would still try another known good coil one more time, only since you have done other things since then.

Make absolutely sure the coil connection is good, use some electronics cleaner but MAKE SURE the connector is DRY before re-connecting.

My go-to in a situation like this will always be a can of BG44K, not any other treatment, but 44K specifically. Then I would re-evaluate after a tankful. It's pricey, but no snake oil.

Still not ruling out another plug/coil if all else fails. After that, then more in-depth digging will be needed.

I did the thing with the exhaust about 2-3 days ago and the piece of paper kept getting sucked back to the tailpipe.... What's this actually mean????

Okay where can I purchase this and what do I do with it????Usually means an exhaust valve isn't fully seating. When the piston moves back down, it momentarily pulls the exhaust gases back.

I would run a can of BG44K.

gmcman

Member

- Dec 12, 2011

- 4,656

Amazon has decent prices, most dealerships. Empty contents into fuel tank when you fill it up. Needs a full tank and best to add during fill up.

Will it fix your problem? Hard to say. But given the symptoms, IMHO, it's worth the $30 to try. I would absolutely take the chance.

If you have any carbon under the valve seat, this stuff works quick to dissolve it.

Will it fix your problem? Hard to say. But given the symptoms, IMHO, it's worth the $30 to try. I would absolutely take the chance.

If you have any carbon under the valve seat, this stuff works quick to dissolve it.