- Apr 9, 2012

- 979

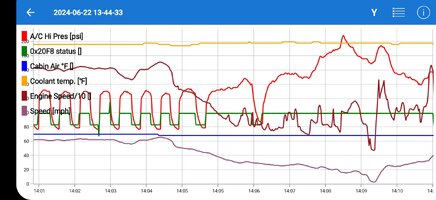

I forgot to setup Torque to data log everything while driving home from work this afternoon.

With the truck idling/at operating temp, Torque is reading about 220-245 PSI. While driving *during moderator acceleration* it went up to 240-280. While coasting, I noticed the pressure would fluctuate a lot (this is where I question if its normal).

Temps today at 94* at 43% humidity.

Driving steady @ 40 MPH (with phone mounted in eye sight) these were the readings I was able to catch. I didn't catch the rate/how high it got during moderate/light acceleration.

230

240

224

228

230

200

198

190

185

200

215

218

220

236

245

255

225

Slowing down from 40 by letting off the gas/braking and staying at a stop (at this point I could feel the vents start blowing luke warm, before it switched back to being cool. It stayed at 50* from the vents, and would go back to 60* when coming to a stop, or slowing down.

190

198

170

160

130

142

140

130

124

150

170

180

200

230

250

I tried my best to memorize each point it reached, like I said I'm going to configure Torque to record the data logs for the high pressure side tomorrow, and upload them here to get a better/more consistent idea of how much its fluctuating.

With the truck idling/at operating temp, Torque is reading about 220-245 PSI. While driving *during moderator acceleration* it went up to 240-280. While coasting, I noticed the pressure would fluctuate a lot (this is where I question if its normal).

Temps today at 94* at 43% humidity.

Driving steady @ 40 MPH (with phone mounted in eye sight) these were the readings I was able to catch. I didn't catch the rate/how high it got during moderate/light acceleration.

230

240

224

228

230

200

198

190

185

200

215

218

220

236

245

255

225

Slowing down from 40 by letting off the gas/braking and staying at a stop (at this point I could feel the vents start blowing luke warm, before it switched back to being cool. It stayed at 50* from the vents, and would go back to 60* when coming to a stop, or slowing down.

190

198

170

160

130

142

140

130

124

150

170

180

200

230

250

I tried my best to memorize each point it reached, like I said I'm going to configure Torque to record the data logs for the high pressure side tomorrow, and upload them here to get a better/more consistent idea of how much its fluctuating.

Is possible that the high pressure sensor works in both directions. Basically, cycling the system on and off ... on when the pressure is low but NOT as low as the low pressure "safety switch" and then off when the pressure reaches some point as determined by the pcm for the system and environment.

Is possible that the high pressure sensor works in both directions. Basically, cycling the system on and off ... on when the pressure is low but NOT as low as the low pressure "safety switch" and then off when the pressure reaches some point as determined by the pcm for the system and environment.