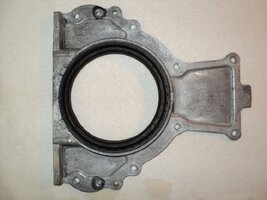

@Sparky ... Yes... it would seem very logical to use the High Grade Steel Studs and Bolts from ARP... but the problem in doing so involves how much the Aluminum Block Substrate is capable of EXPANDING and CONTRACTING. Ordinarily... Cast Iron and Steel expand and contract at the rate of 1/64,000,000" per degree Fahrenheit as it either Heats up ...or Cools down. Aluminum, however responds to those increases and decreases in temperature with a much greater level of Expansion and Contraction... such to the extent that with RIGID STEEL STUDS AND BOLTS... the affect of such a restrictive holding force would either damage the Aluminum Mating Points and Strip Out the Bolt Holes and Thread lines inside the softer Aluminum Block...or simply fracture and break off the Hardened Steel Fasteners.

The GM Engineers decided to give a kind of "Systemic Stretchability" to the Aluminum Engine Block and Head that is allowed because the TTY Fasteners STRETCH when the Engine Block and Head HEAT UP... and have a kind of "Elastic Rebound" to return to their more relaxed state when the Engine Cools Down... and yet...STILL maintain their Torque and Gripping Power.

This entire Atlas Engine behaves more like a "Metal Balloon" in this regard and this gives a wonderful reason of what happens to the Non-TTY Fasteners that repeatedly Snap Off and fail that hold the Rigid Cast Iron Exhaust Manifold alongside the more Balloon like Aluminum Head. Part of the reason they break off is because these large, very different metal surfaces expand and contract at markedly different rates and the Bolts holding them together lack the matching elasticity of the HEAD BOLTS, and CRANKSHAFT CRADLE BOLTS... and all too often...Fail as the result.

The GM Engineers decided to give a kind of "Systemic Stretchability" to the Aluminum Engine Block and Head that is allowed because the TTY Fasteners STRETCH when the Engine Block and Head HEAT UP... and have a kind of "Elastic Rebound" to return to their more relaxed state when the Engine Cools Down... and yet...STILL maintain their Torque and Gripping Power.

This entire Atlas Engine behaves more like a "Metal Balloon" in this regard and this gives a wonderful reason of what happens to the Non-TTY Fasteners that repeatedly Snap Off and fail that hold the Rigid Cast Iron Exhaust Manifold alongside the more Balloon like Aluminum Head. Part of the reason they break off is because these large, very different metal surfaces expand and contract at markedly different rates and the Bolts holding them together lack the matching elasticity of the HEAD BOLTS, and CRANKSHAFT CRADLE BOLTS... and all too often...Fail as the result.