I recently picked up an 02 TB for my daughter to drive when she turns 16 early next year. Had 193k and needed a little work but ran and drove and was only $1500. Body and interior are in great shape and thought we got a great deal.

Got it home, changed the oil, air filter and spark plugs and topped off the tranny fluid. Took it for a test drive and engine died down the street and wouldnt restart. Engine seized up and wont turn over by hand 😭 turned out to be a spun rod bearing on #3 cylinder.

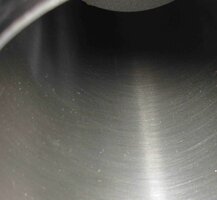

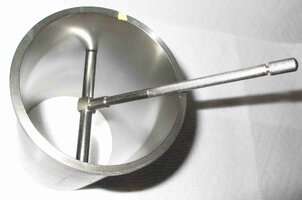

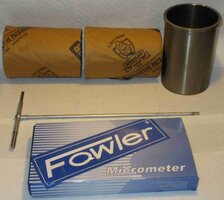

Fast forward to me reading alot of stuff on the web, including this forum and MRRSM’s thread on his rebuild. I currently have the engine down to bare block for the rebuild and found that my cylinder sleeves were scored and one had a crack. Sooo, I sourced the kent moore cylinder sleeve tool and the melling replacement sleeves (along with alot of other parts I have been gathering) which arrived Friday.

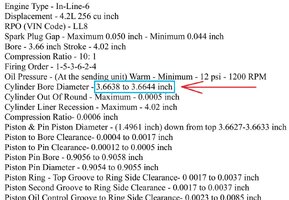

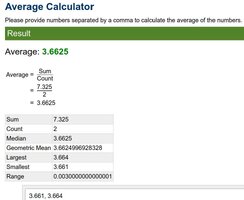

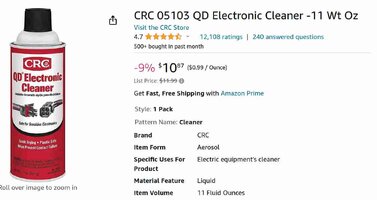

I was able to pull the factory sleeves with no issues (like butter!), but am struggling with the install of the new sleeves. I cleaned the bores in the block and the new sleeves, but the first one got down to about an inch out of the hole and became really difficult to turn any further. I tried a second sleeve/bore and it went in an inch or so and again is really hard to crank the ratchet. I don’t think it should be that hard to crank.

Can anyone provide any insight on this part of the procedure that might get me over the hump? Wife is already ready to kill me on this project 🙈 Thanks!

Got it home, changed the oil, air filter and spark plugs and topped off the tranny fluid. Took it for a test drive and engine died down the street and wouldnt restart. Engine seized up and wont turn over by hand 😭 turned out to be a spun rod bearing on #3 cylinder.

Fast forward to me reading alot of stuff on the web, including this forum and MRRSM’s thread on his rebuild. I currently have the engine down to bare block for the rebuild and found that my cylinder sleeves were scored and one had a crack. Sooo, I sourced the kent moore cylinder sleeve tool and the melling replacement sleeves (along with alot of other parts I have been gathering) which arrived Friday.

I was able to pull the factory sleeves with no issues (like butter!), but am struggling with the install of the new sleeves. I cleaned the bores in the block and the new sleeves, but the first one got down to about an inch out of the hole and became really difficult to turn any further. I tried a second sleeve/bore and it went in an inch or so and again is really hard to crank the ratchet. I don’t think it should be that hard to crank.

Can anyone provide any insight on this part of the procedure that might get me over the hump? Wife is already ready to kill me on this project 🙈 Thanks!