Hey everyone, I'm having an issue with my 2003 Silverado 1500 LS where it turns over just fine, then immediately stalls out. I've searched all over and cannot find a solution. The fuel pump is less than a year old and I've tried the security system re set. It also doesn't do it all the time, it began the issue then seemed to solve itself for about 3 weeks then stalled out again. It doesn't have a rough idle and hasn't stalled out while driving, even with excessive miles on the highway. Just getting the thing to start is the issue

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

NEED HELP Start-Stall on a 2003 Chevy 5.3

- Thread starter Kgurn1020

- Start date

Mooseman

Moderator

or a complete tune up?

What brand fuel pump did you use? Check the fuel pressure as it could also be the fuel pressure regulator or a leak. Check for vacuum leaks, especially around the intake manifold.

What brand fuel pump did you use? Check the fuel pressure as it could also be the fuel pressure regulator or a leak. Check for vacuum leaks, especially around the intake manifold.

I replaced the fuel pump with a new one about 6-7 month's ago, I checked the fuel pressure and seemed normalWhen was the fuel filter last replaced?

I found a broken ground near the fuel tank on the rear drivers side. Looks to have snapped years ago but idk if that's the issue, also have no idea as to where the other end goes.Check out the Ground (Bonding Strap) connecting the Firewall to the Back Passenger side of the Engine Head. These Video describes many of the Electrical problems that can occur if that Ground BREAKS Loose:

Attachments

Good Searching... First... Visit THIS Link and after identifying the GM OEM Digital Service Manual... Follow the Login and Password Instructions provided by @Mooseman that will allow you to Download a FREE version for your Silverado:

gmtnation.com

gmtnation.com

Next... have a look at this Article:

vehiclefreak.com

vehiclefreak.com

Because ALL Trucks have the Three Major Sections that MUST be Bonded and Grounded together (The Cab, Truck Frame and Bed) ...AND... due to the Crusted - Up deeply Rusted Under Body conditions present in your images, *Best Practices* would suggest performing an R&R of ALL of those Under Body and Frame Ground Contact Points and follow the suggestions outlined in the First Video.

After cleaning their surfaces back down to Bare Metal... apply a small amount of Dielectric Grease and then secure all those Straps with the correct Fasteners and Spray a Splash of Under-Body Black Paint over them.

Under ordinary circumstances...whenever "EZ Grounds" are compromised in any circuit bad enough to pose any difficulty with Current Flow... for say the PCM ...or any other circuit impeded by Rust and Corrosion, the Electrical Current will STILL try to reach Ground to the B(-) Battery Negative through any other available means possible and FUBAR other Electrical Circuits in the Vehicle.

Check the Service Manual for the Ground Locations

Wear Protective Goggles

Use a Bright Flashlight

Use Dielectric Grease and Black Under-Body Paint for Final Prep

Charge the Battery

Start the Vehicle and TEST the system by turning on High Current Accessories and observe the Dash-IPC Volt-Meter for excessive Low Voltage Fluctuations.

Check the Connections at the Alternator if the Voltage drops TOO Low.

Full Size Service Manuals

Thanks to our good friend @Reprise , we now have a set for full size trucks. Although these are specifically for 1998-2006 Silverado and Sierra, these will also be useful for Tahoe and Suburban owners. Full Size GM Truck Service Manuals (655.7 MB) NOTE: This is a specific login to download...

Next... have a look at this Article:

Where Are The Chevy Truck Ground Locations?

Electrical systems in vehicles are grounded to the frame or body to complete the circuit. The Chevy truck is no different and has multiple grounding points

Because ALL Trucks have the Three Major Sections that MUST be Bonded and Grounded together (The Cab, Truck Frame and Bed) ...AND... due to the Crusted - Up deeply Rusted Under Body conditions present in your images, *Best Practices* would suggest performing an R&R of ALL of those Under Body and Frame Ground Contact Points and follow the suggestions outlined in the First Video.

After cleaning their surfaces back down to Bare Metal... apply a small amount of Dielectric Grease and then secure all those Straps with the correct Fasteners and Spray a Splash of Under-Body Black Paint over them.

Under ordinary circumstances...whenever "EZ Grounds" are compromised in any circuit bad enough to pose any difficulty with Current Flow... for say the PCM ...or any other circuit impeded by Rust and Corrosion, the Electrical Current will STILL try to reach Ground to the B(-) Battery Negative through any other available means possible and FUBAR other Electrical Circuits in the Vehicle.

Check the Service Manual for the Ground Locations

Wear Protective Goggles

Use a Bright Flashlight

Use Dielectric Grease and Black Under-Body Paint for Final Prep

Charge the Battery

Start the Vehicle and TEST the system by turning on High Current Accessories and observe the Dash-IPC Volt-Meter for excessive Low Voltage Fluctuations.

Check the Connections at the Alternator if the Voltage drops TOO Low.

Last edited:

I will definitely be trying that tomorrow, would you be able to know how many body grounds there are? I don't know how knowledgeable you are on that series of Silverado's. I located 2 towards the front drivers side as well as the broken one near the fuel pump. However I can't seem to find where that one (near fuel pump in photos) grounds too.Good Searching... First... Visit THIS Link and after identifying the GM OEM Digital Service Manual... Follow the Login and Password Instructions provided by @Mooseman that will allow you to Download a FREE version for your Silverado:

Full Size Service Manuals

Thanks to our good friend @Reprise , we now have a set for full size trucks. Although these are specifically for 1998-2006 Silverado and Sierra, these will also be useful for Tahoe and Suburban owners. Full Size GM Truck Service Manuals (655.7 MB) NOTE: This is a specific login to download...gmtnation.com

Next... have a look at this Article:

Where Are The Chevy Truck Ground Locations?

Electrical systems in vehicles are grounded to the frame or body to complete the circuit. The Chevy truck is no different and has multiple grounding pointsvehiclefreak.com

Because ALL Trucks have the Three Major Sections that MUST be Bonded and Grounded together (The Cab, Truck Frame and Bed) ...AND... due to the Crusted - Up deeply Rusted Under Body conditions present in your images, *Best Practices* would suggest performing an R&R of ALL of those Under Body and Frame Ground Contact Points and follow the suggestions outlined in the First Video.

After cleaning their surfaces back down to Bare Metal... apply a small amount of Dielectric Grease and then secure all those Straps with the correct Fasteners and Spray a Splash of Under-Body Black Paint over them.

Under ordinary circumstances...whenever "EZ Grounds" are compromised in any circuit bad enough to pose any difficulty with Current Flow... for say the PCM ...or any other circuit impeded by Rust and Corrosion, the Electrical Current will STILL try to reach Ground to the B(-) Battery Negative through any other available means possible and FUBAR other Electrical Circuits in the Vehicle.

Check the Service Manual for the Ground Locations

Wear Protective Goggles

Use a Bright Flashlight

Use Dielectric Grease and Black Under-Body Paint for Final Prep

Charge the Battery

Start the Vehicle and TEST the system by turning on High Current Accessories and observe the Dash-IPC Volt-Meter for excessive Low Voltage Fluctuations.

Check the Connections at the Alternator if the Voltage drops TOO Low.

Sure... (RTFM) and ALL of the Body Grounds are mentioned in THIS Article:

vehiclefreak.com

vehiclefreak.com

The Fuel Pump Harness includes Three Wires:

(1) 12 Volts DC Power

(2) PWM (Pulse Width Modulation) Signal Wire

(3) Discreet Ground Wire (...because the FP is nested inside of the Plastic Fuel Tank)

ALL Braided Copper or Tinned-Copper Straps are Grounds that get bolted up to The Chassis, The Cab Body or the Under-Frame areas and other components and are readily visible all around most vehicles with a careful inspection. So wherever you find any of them... Just R&R and Prep them as per the aforementioned suggestions.

Where Are The Chevy Truck Ground Locations?

Electrical systems in vehicles are grounded to the frame or body to complete the circuit. The Chevy truck is no different and has multiple grounding points

The Fuel Pump Harness includes Three Wires:

(1) 12 Volts DC Power

(2) PWM (Pulse Width Modulation) Signal Wire

(3) Discreet Ground Wire (...because the FP is nested inside of the Plastic Fuel Tank)

ALL Braided Copper or Tinned-Copper Straps are Grounds that get bolted up to The Chassis, The Cab Body or the Under-Frame areas and other components and are readily visible all around most vehicles with a careful inspection. So wherever you find any of them... Just R&R and Prep them as per the aforementioned suggestions.

Last edited:

I believe the snapped ground is the fuel neck ground. it looks like it broke years ago so I doubt that's the issue. However it's a start. Other than the electrical system I'm not sure what else could be causing the issue. It's sporadic with its issue, not starting for days then randomly running fine and being able to drive hundreds of miles before stalling out next time I start it days laterSure... (RTFM) and ALL of the Body Grounds are mentioned in THIS Article:

Where Are The Chevy Truck Ground Locations?

Electrical systems in vehicles are grounded to the frame or body to complete the circuit. The Chevy truck is no different and has multiple grounding pointsvehiclefreak.com

The Fuel Pump Harness includes Three Wires:

(1) 12 Volts DC Power

(2) PWM (Pulse Width Modulation) Signal Wire

(3) Discreet Ground Wire (...because the FP is nested inside of the Plastic Fuel Tank)

ALL Braided Copper or Tinned-Copper Straps are Grounds that get bolted up to The Chassis, The Cab Body or the Under-Frame areas and other components and are readily visible all around most vehicles with a careful inspection. So wherever you find any of them... Just R&R and Prep them as per the aforementioned suggestions.

Update: I just checked the fuel pressure, at idle it's around 45 psi, and with acceleration it doesnt even top 50. I think that may be the issue. Would that be the new pump or possibly the pressure regulator ?

According to AllData-DIY... The 2006 GMC Envoy Denali with the 5.3L Engine A4 4L60E Transmission, Fuel Pressure should be in THIS Range:

(Key ON, Engine OFF) 385-425 kPa (55-62 psi)

However... If the Engine runs nominally and neither Stalls nor Runs Rough and Fails to throw any P0300-P0306 Codes for signs of Lean Conditions or Stumbling... Then Fuel Pressure is probably not a factor, especially if the replacement Fuel Pump was an OEM Bosch, ACDelco or even a Delphi Brand of Pump.

Source:

gmtnation.com

gmtnation.com

(Key ON, Engine OFF) 385-425 kPa (55-62 psi)

However... If the Engine runs nominally and neither Stalls nor Runs Rough and Fails to throw any P0300-P0306 Codes for signs of Lean Conditions or Stumbling... Then Fuel Pressure is probably not a factor, especially if the replacement Fuel Pump was an OEM Bosch, ACDelco or even a Delphi Brand of Pump.

Source:

What is the correct fuel pressure, 5.3 engine?

So I'm dealing with a hesitation and misfire, in another thread I will start, long story. I just need to know right now what the correct fuel pressure is. I checked the fuel pressure and had a reading of 40 psi. Jumps to 50 when I blip the throttle. I replaced the pump, Bosch. Replaced the...

Last edited:

It doesn't even hit 50 at around 2000rmps. 45 at idle. I'll have to check with the key in the on position although I am afraid to turn it off againAccording to AllData-DIY... The 2006 GMC Envoy Denali with the 5.3L Engine... Fuel Pressure should be in THIS Range: (Key ON, Engine OFF) 385-425 kPa (55-62 psi)

Source:

What is the correct fuel pressure, 5.3 engine?

So I'm dealing with a hesitation and misfire, in another thread I will start, long story. I just need to know right now what the correct fuel pressure is. I checked the fuel pressure and had a reading of 40 psi. Jumps to 50 when I blip the throttle. I replaced the pump, Bosch. Replaced the...gmtnation.com

You know... Just on occasion...there are TSBs that come out indicating that annoying issues like this one might be helped by simply Updating the PCM Calibration with a Tech 2 (and using TIS2000), or by using an MDI or a VXDIAG NANO with access to the ACDelco TDS Online Site and a modest per vehicle fee:

You should also consider examining your Front Suspension for anything in need of replacement as well such As Sketchy Ball Joints, Loosened Brackets, Broken Bumper or Fascia attachments etc. that can act to pick up and amplify vibrations enough to become obvious... only at certain frequencies and amplitudes..

You should also consider examining your Front Suspension for anything in need of replacement as well such As Sketchy Ball Joints, Loosened Brackets, Broken Bumper or Fascia attachments etc. that can act to pick up and amplify vibrations enough to become obvious... only at certain frequencies and amplitudes..

Last edited:

Key in the ON position sits at 25 psi the first time. Turned the key off then back to the ON position now it's at 55It doesn't even hit 50 at around 2000rmps. 45 at idle. I'll have to check with the key in the on position although I am afraid to turn it off again

With a Returnless Fuel Pump System... There could be a weakness in the Internal Check Valve allowing the Pressure to Bleed Off...What was the Brand name of this Year Old Fuel Pump...Non-OEM...Perhaps?

Forgot to ask this earlier...Is the Air Intake System "Stock As A Clock" ? If not...removing the Resonance Chamber designed to absorb and dampen the supersonic sound waves pulsing out of all the Cylinders on each Intake Stroke and then Reflecting back and out through the Intake Manifold ...can become evident afterwards with any Modified or Non-Stock Tubing.

Forgot to ask this earlier...Is the Air Intake System "Stock As A Clock" ? If not...removing the Resonance Chamber designed to absorb and dampen the supersonic sound waves pulsing out of all the Cylinders on each Intake Stroke and then Reflecting back and out through the Intake Manifold ...can become evident afterwards with any Modified or Non-Stock Tubing.

Last edited:

Car Quest I believeWith a Returnless Fuel Pump System... There could be a weakness in the Internal Check Valve allowing the Pressure to Bleed Off...What was the Brand name of this Year Old Fuel Pump...Non-OEM...Perhaps?

Forgot tp ask this earlier...Is the Air Intake System "Stock As A Clock" ? If not...removing the Resonance Chamber designed to absorb and dampen the supersonic sound waves pulsing out of all the Cylinders on each Intake Stroke and then Reflecting back and out through the Intake Manifold ...can become evident afterwards with any Modified or Non-Stock Tubing.

How should I go about diagnosing the fuel injector regulator? Seems like that could be the issueHmmm...

If you are having any problems with the Fuel Pressure Regulator...it may be Leaking Fuel into the FPR Vacuum Line as an indication of an impending failure. THIS Article should Help:

www.motoraudit.com

www.motoraudit.com

HERE is How to R&R The Fuel Pressure Regulator:

...and another Pro Mechanic's impression...

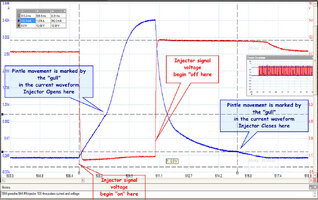

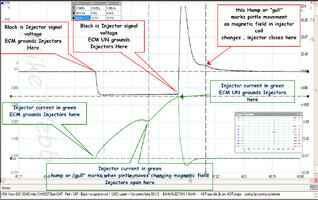

EFI Diagnostics:

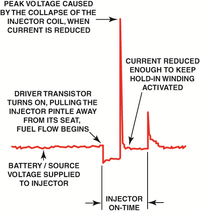

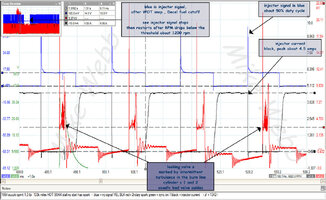

Modern GM Multec II Fuel Injectors are simply "Fancy Solenoids" that are controlled using PWM Signals (Pulse Width Modulation) coming from the PCM (Power Train Control Module) and produce very discreet bursts of Atomized Fuel controlling the ON Time that the EFI Pintles assume to stay Open, supported by the Constant, Regulated Fuel Pressure feeding through the Fuel Rail(s) from the Electric Fuel Pump.

Caveat Emptor:

If the EFIs are NOT Performing Properly... the PCM WILL Flag itself due to Lean Misfires; either a P0300 (possibly caused by a Vacuum Leak or Ignition Issues) ...or... a P0301 - P0308 on a V8 Engine as occurring on either Bank 0 or Bank 1, depending upon where the Poorly Performing EFI is situated. The Chances that a P0300 will occur and point to a Failure of ALL of the EFIs at once... is simply Astronomically Unlikely.

To be more comprehensive... Modern GM Engines control the AIR entering the Intake System by measuring it as fractions of Gram Weight - Per Second by means of a (MAF) Mass Air Flow Sensor informing the PCM to add this information and adding to its Engine Regulation calculus. Likewise, taking the Temperature of the Air on the way into the Throttle Body using the (IAT) Inlet Air Temperature Sensor is a necessary part of this calculus.

The PCM is always trying to establish the "Driver's Intent" by using the position of the (ACC) Module (Gas Pedal) along with the positions registered by the (TBS) Throttle Body Sensor AKA (TAC) Throttle Actuator Control Module for determining the physical location of the Butterfly Throttle Plate at all times. These Multiple inputs help to inform the PCM.

Other Sensors are also at play here that include the (MAP) Maximum Absolute Pressure Sensor present to measure the amount of Vacuum inside the Intake Manifold as well as the (VSS) Vehicle Speed Sensor mounted to pick up the RPM at the Transmission Output Drive Shaft all coordinating as a protective mechanism against allowing Fuel to be injected if the "Driver's Intent" is to either Drive SLOWLY or if the Driver has applied the Brake Pedal in order to STOP or SLOW the Vehicle.

The Upstream O2 Sensor mounted in the Exhaust Manifold gets the First Taste of the Exhaust Plume coming from all of the Cylinders to determine whether or not the "MIX" or 'Right Ratio of Air to Fuel' (14.7:1) at Sea Level is occurring at all times.

The Oxygen Sensor measures the amount of "Spare Oxygen" left over in the Exhaust Stream AFTER Combustion and thus, will inform the PCM of just how Efficient (or Inefficient) its Decision Making has been with allowing Sufficient (or NOT Enough) Fuel to get Sprayed from the EFI's into all of the Cylinders at any given moment In Balance with the Weighed-In Naturally Aspirated AIR.

This entire process is accomplished by the PCM being able to use "Controlled, Measured, Metered Amsounts of AIR" as its Prime Concern ...and is NOT like The Carburetors of Old, where the Fuel Delivery Method was provoked using the Cylinder Vacuum and a Venturi Shaped Intake Throat in its Opening (Bernoulli's Principle) as the Dominant means for ingesting Gasoline Vapors. But ... If the Modern GM PCM gets even slightly *confused* by the misdirection from ANY of these Sensors... its Default Software Calibration Safety Protocol response is to cause the Engine to SHUNT into a Reduced Power Mode.

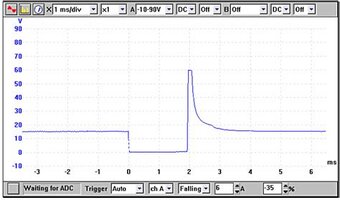

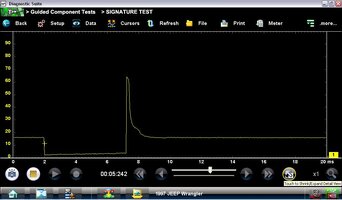

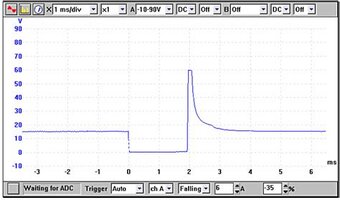

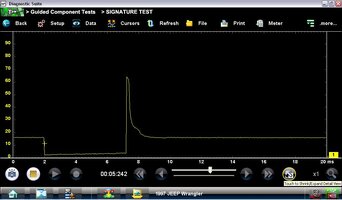

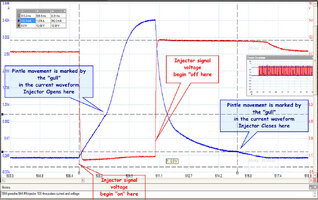

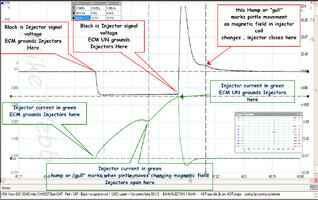

It is impossible to visualize how well or how inefficient the EFIs are performing without using an Oscilloscope. This device is capable of taking a VERY High Number of Signal Samples in Minuscule Slices of Time, either ALL AT ONCE by using a Low Amperage Current Clamp (By Induction) applied upon the 12 Volt Power Feed Wire (Primary Voltage Side) of the EFI Array in what is called a "Parade" or... Singly of only One Fuel Injector IN ACTION at a time after Back-Probing its Signal Wire and then viewing its LIVE (Secondary Voltage Side) Wave Form Behavior On Screen.

The "SHAPES" or "WAVE FORMS" of these Electrical Signals are displayed On Screen as "Voltage Over Time" using an X-Y Axis and with the knowledge of useful "Known GOOD Wave Forms" versus whatever Live Wave Forms show up on the Oscilloscope Screen that lend themselves to make such comparisons. Using the unique, collected examples of "Known GOOD Wave Forms " from other's Library of Experiences... a Good Automotive Diagnostician will be able to determine just How Well (or How Poorly) the EFIs are performing.

THIS Video is a CLASSIC Example of How to Use an Inexpensive Hantek Model #1008C Oscilloscope to Back Probe an array of Fuel Injectors and View their Performances On Screen. THIS is an Illustration of what a Normal "GOOD KNOWN" EFI Wave Form SHOULD look like:

If you are interested... More Training and Instructions on "How To Use An Inexpensive Oscilloscope" can be found at THIS Link:

gmtnation.com

gmtnation.com

9 Symptoms Of A Bad Fuel Pressure Regulator On 5.3 Vortec

Are you experiencing fuel pressure issues with your 5.3 Vortec engine? It could be a faulty fuel pressure regulator. Learn more and fix the issue today!

HERE is How to R&R The Fuel Pressure Regulator:

...and another Pro Mechanic's impression...

EFI Diagnostics:

Modern GM Multec II Fuel Injectors are simply "Fancy Solenoids" that are controlled using PWM Signals (Pulse Width Modulation) coming from the PCM (Power Train Control Module) and produce very discreet bursts of Atomized Fuel controlling the ON Time that the EFI Pintles assume to stay Open, supported by the Constant, Regulated Fuel Pressure feeding through the Fuel Rail(s) from the Electric Fuel Pump.

Caveat Emptor:

If the EFIs are NOT Performing Properly... the PCM WILL Flag itself due to Lean Misfires; either a P0300 (possibly caused by a Vacuum Leak or Ignition Issues) ...or... a P0301 - P0308 on a V8 Engine as occurring on either Bank 0 or Bank 1, depending upon where the Poorly Performing EFI is situated. The Chances that a P0300 will occur and point to a Failure of ALL of the EFIs at once... is simply Astronomically Unlikely.

To be more comprehensive... Modern GM Engines control the AIR entering the Intake System by measuring it as fractions of Gram Weight - Per Second by means of a (MAF) Mass Air Flow Sensor informing the PCM to add this information and adding to its Engine Regulation calculus. Likewise, taking the Temperature of the Air on the way into the Throttle Body using the (IAT) Inlet Air Temperature Sensor is a necessary part of this calculus.

The PCM is always trying to establish the "Driver's Intent" by using the position of the (ACC) Module (Gas Pedal) along with the positions registered by the (TBS) Throttle Body Sensor AKA (TAC) Throttle Actuator Control Module for determining the physical location of the Butterfly Throttle Plate at all times. These Multiple inputs help to inform the PCM.

Other Sensors are also at play here that include the (MAP) Maximum Absolute Pressure Sensor present to measure the amount of Vacuum inside the Intake Manifold as well as the (VSS) Vehicle Speed Sensor mounted to pick up the RPM at the Transmission Output Drive Shaft all coordinating as a protective mechanism against allowing Fuel to be injected if the "Driver's Intent" is to either Drive SLOWLY or if the Driver has applied the Brake Pedal in order to STOP or SLOW the Vehicle.

The Upstream O2 Sensor mounted in the Exhaust Manifold gets the First Taste of the Exhaust Plume coming from all of the Cylinders to determine whether or not the "MIX" or 'Right Ratio of Air to Fuel' (14.7:1) at Sea Level is occurring at all times.

The Oxygen Sensor measures the amount of "Spare Oxygen" left over in the Exhaust Stream AFTER Combustion and thus, will inform the PCM of just how Efficient (or Inefficient) its Decision Making has been with allowing Sufficient (or NOT Enough) Fuel to get Sprayed from the EFI's into all of the Cylinders at any given moment In Balance with the Weighed-In Naturally Aspirated AIR.

This entire process is accomplished by the PCM being able to use "Controlled, Measured, Metered Amsounts of AIR" as its Prime Concern ...and is NOT like The Carburetors of Old, where the Fuel Delivery Method was provoked using the Cylinder Vacuum and a Venturi Shaped Intake Throat in its Opening (Bernoulli's Principle) as the Dominant means for ingesting Gasoline Vapors. But ... If the Modern GM PCM gets even slightly *confused* by the misdirection from ANY of these Sensors... its Default Software Calibration Safety Protocol response is to cause the Engine to SHUNT into a Reduced Power Mode.

It is impossible to visualize how well or how inefficient the EFIs are performing without using an Oscilloscope. This device is capable of taking a VERY High Number of Signal Samples in Minuscule Slices of Time, either ALL AT ONCE by using a Low Amperage Current Clamp (By Induction) applied upon the 12 Volt Power Feed Wire (Primary Voltage Side) of the EFI Array in what is called a "Parade" or... Singly of only One Fuel Injector IN ACTION at a time after Back-Probing its Signal Wire and then viewing its LIVE (Secondary Voltage Side) Wave Form Behavior On Screen.

The "SHAPES" or "WAVE FORMS" of these Electrical Signals are displayed On Screen as "Voltage Over Time" using an X-Y Axis and with the knowledge of useful "Known GOOD Wave Forms" versus whatever Live Wave Forms show up on the Oscilloscope Screen that lend themselves to make such comparisons. Using the unique, collected examples of "Known GOOD Wave Forms " from other's Library of Experiences... a Good Automotive Diagnostician will be able to determine just How Well (or How Poorly) the EFIs are performing.

THIS Video is a CLASSIC Example of How to Use an Inexpensive Hantek Model #1008C Oscilloscope to Back Probe an array of Fuel Injectors and View their Performances On Screen. THIS is an Illustration of what a Normal "GOOD KNOWN" EFI Wave Form SHOULD look like:

If you are interested... More Training and Instructions on "How To Use An Inexpensive Oscilloscope" can be found at THIS Link:

How To Use PICO #2204A & HANTEK #1008C Oscilloscopes

You don't need a Huge Bag of Coins in order to obtain and use an Oscilloscope for performing In-Depth Wave Form Analysis in Automotive Applications on everything from Problematic Electronic Fuel Injection to obtaining accurate Compression Tests to Diagnose Internal Engine Conditions. HANTEK...

Attachments

Last edited:

Funny enough, I did the Passlock Reset for the passlock system (turning the key to ON for 10 minutes for 3 times) and the Truck started right up. Not sure if that was the issue but it could be. It also through up that P0300 code you mentioned when I put the OBD to it after it started. So it seems like everytime I take 1 step closer to pinpointing the issue I take 2 back and 1 to the sideModern GM Multec II Fuel Injectors are simply "Fancy Solenoids" that are controlled using PWM Signals (Pulse Width Modulation) coming from the PCM (Power Train Control Module) and produce very discreet bursts of Atomized Fuel controlling the ON Time that the EFI Pintles stay Open supported by the constant Fuel Pressure feeding through the Fuel Rail(s) from the Electric Fuel Pump.

Caveat Emptor:

If the EFIs are NOT Performing Properly... the PCM WILL Flag a P0300 (caused by a Vacuum Leak) ...or... a P0301 - P0308 on a V8 Engine as occurring on either Bank 0 or Bank 1, depending upon where the Poorly Performing EFI is situated. The Chances that a P0300 will occur and point to a Failure of ALL of the EFIs at once... is simply Astronomically Unlikely.

To be more comprehensive... GM controls AIR entering the Intake System measuring it by Gram Weight - per second by means of a (MAF) Mass Air Flow Sensor and by taking its Temperature on the way into the Throttle Body using the (IAT) Inlet Air Temperature Sensor. The PCM is always trying to establish the "Driver's Intent" using the position of the (ACC) Module (Gas Pedal) along with the positions registered by the (TBS) Throttle Body Sensor for the physical location of the Butterfly Throttle Plate.

Other Sensors are also at play here that include the (MAP) Maximum Absolute Pressure) sensor present to measure the amount of Vacuum inside the Intake Manifold as well as the (VSS) Vehicle Speed Sensor mounted to pick up the RPM at the Transmission Output Drive Shaft all coordinating as a protective mechanism against allowing Fuel to be injected if the "Driver's Intent" is to either Drive SLOWLY or if the Driver has applied the Brake Pedal in order to STOP or SLOW the Vehicle.

The Upstream O2 Sensor mounted in the Exhaust Manifold gets the First Taste of the Exhaust plume coming from all of the Cylinders to determine whether or not the "MIX" or Right Ratio of Air to Fuel (14.7:1) at Sea Level is occurring at all times. The Oxygen Sensor informs the PCM of just how efficient (or inefficient) its Decision Making has been with allowing sufficient (or NOT enough) Fuel to get sprayed from the EFI's into all of the Cylinders at any given moment In Balance with the Weighed-In Naturally Aspirated AIR.

This entire process is accomplished by the PCM being able to use "Controlled, Measured, Metered AIR" as its Prime Concern ...and is NOT like the Carburetors of Old, where the Fuel Delivery Method was Dominant. IF the PCM gets even slightly *confused* by ANY of these Sensors... its Safety Protocol Response is to cause the Engine to SHUNT into a Reduced Power Mode.

It is impossible to visualize how well or how inefficient the EFIs are performing without using an Oscilloscope. This device is capable of taking a VERY High Number of Signal Samples, either ALL AT ONCE on what is called "A Parade" and Singly of Only One Fuel Injector IN ACTION and view its behavior On Screen.

The "SHAPES" or "WAVE FORMS" of these Electrical Signals are displayed On Screen as "Voltage Over Time" using an X-Y Axis and the use of "Known GOOD wave Forms" versus what shows up on the Oscilloscope Screen lend themselves to comparison. Using the collected examples of GOOD Wave Forms from other's experiences... a Good Automotive Diagnostician will be able to determine How Well (or How Poorly) the EFIs are performing.

THIS Video is a CLASSIC Example of How to Use an Inexpensive Hantek Model #1008C Oscilloscope to Back Probe an array of Fuel Injectors and View their Performances On Screen. THIS is an Illustration of what a Normal "GOOD KNOWN" EFI Wave Form SHOULD look like:

View attachment 107693View attachment 107696View attachment 107697View attachment 107698View attachment 107702

If the Fuel Filter needed replacement when the Year Old CarQuest Fuel Pump R&R was done... Consider doing so now by using THIS Quality K&N Brand In-Line Fuel Filter...

...and if the Fuel Pressure Regulator Vacuum Line or its Rubber End Fittings are damaged... This is the Replacement Part to get:

...and if the Fuel Pressure Regulator Vacuum Line or its Rubber End Fittings are damaged... This is the Replacement Part to get:

Attachments

There IS another High Quality OEM replacement Fuel Pressure Regulator made by Delphi that is made of Stainless Steel and fitted with a Large and a Small set of "Fuel Proof" Pale Green Silicone Rubber "O" Rings. They deserve a light coating of Motor Oil prior to the insertion of this Unit AFTER ensuring that the smaller of the two on the Old Unit gets pulled loose using a Curved Pick if it happens to gets stuck inside the Port upon its removal.

Paying attention to these details matter because in the case of performing this exchange on the 1/2 Ton Full Size GM and GMC Trucks, it won't be obvious and thus, it will otherwise be impossible to install the new one since it requires a difficult look and a reach without standing on a Small Foot Stool in order to improve your comfortable access to that area.

Here is a Photo-Play of this Fuel Pressure Regulator:

Paying attention to these details matter because in the case of performing this exchange on the 1/2 Ton Full Size GM and GMC Trucks, it won't be obvious and thus, it will otherwise be impossible to install the new one since it requires a difficult look and a reach without standing on a Small Foot Stool in order to improve your comfortable access to that area.

Here is a Photo-Play of this Fuel Pressure Regulator:

Last edited:

Hello everyone I apologize for the late response but I wanted to give it a month or so to make sure I had solved the issue. Turns out it was the anti theft system. For whatever reason it decided to freak out and cause the issue. The reset method with turning the key in the on position 3 times for 30 minutes worked.